Zinc oxide single crystal polishing technology for substrate of photoelectric device

A zinc oxide single crystal, zinc oxide technology, applied in the direction of grinding equipment, grinding machine tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific steps of the zinc oxide single crystal polishing method that can be used for optoelectronic device substrates provided by the present invention are as follows:

[0034] 1) Single crystal rough grinding: use 320~500 Cw sandpaper to artificially grind the surface of the cut zinc oxide single crystal with a thickness of about 1.0 mm, and the surface of the zinc oxide wafer has no saw marks;

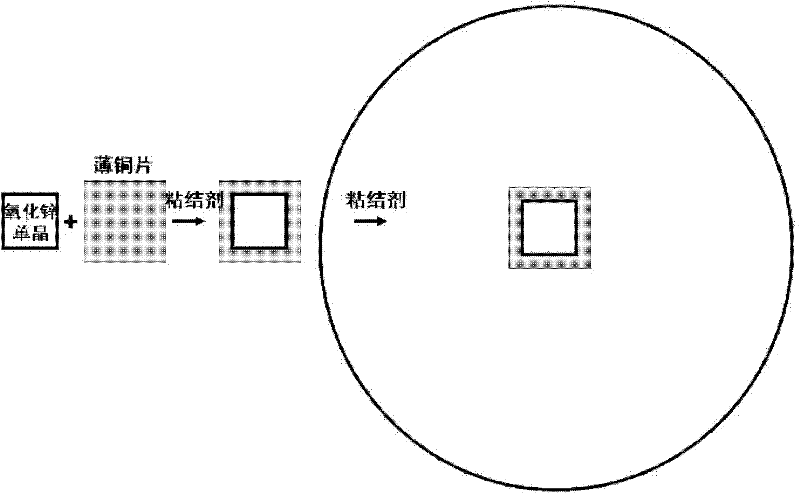

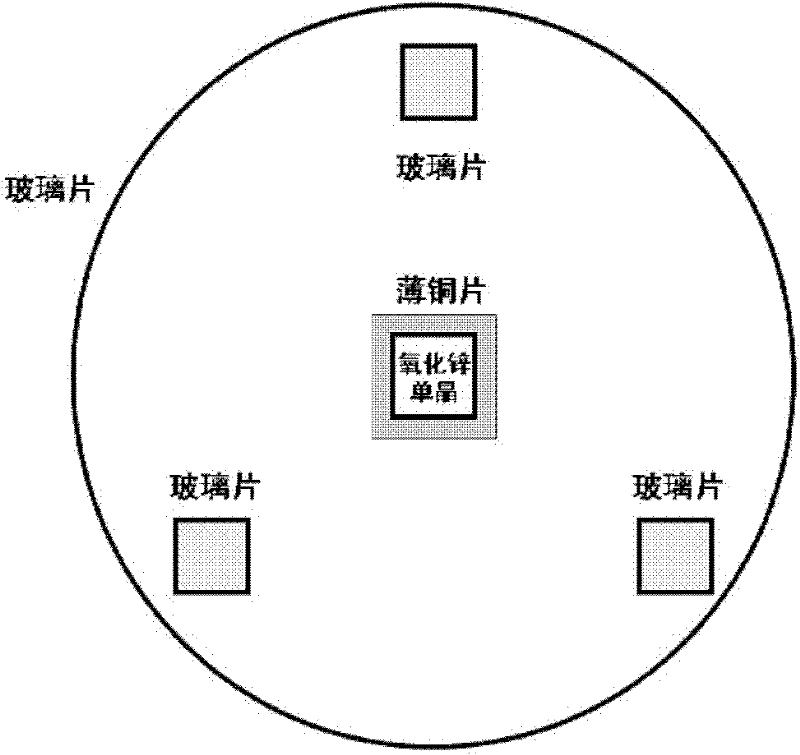

[0035]2) Bonding plate: use 320~500 Cw sandpaper to chamfer the roughly ground zinc oxide wafer with a thickness of about 0.8 mm (see the attached figure 1 ), place the chamfered wafer on the platform of a temperature-controlled / cooled pressurized die bonder for heating, the heating temperature is 80-110 °C, and then use a heated special adhesive to apply it on the upper surface of the wafer while it is hot, and finally Use a cylindrical stainless steel press cake with a diameter of 9 cm to press on the wafer, and the pressure on the wafer is 100~200 g / cm 2 ; After 5 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com