Thermal treatment process for saw web

A saw blade and process technology, which is applied in the field of saw blade heat treatment process, can solve the problems of not meeting the flatness requirements of high-level saw blades, reducing the saw blade, etc., and achieve the effect of reducing the probability of deformation and improving the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

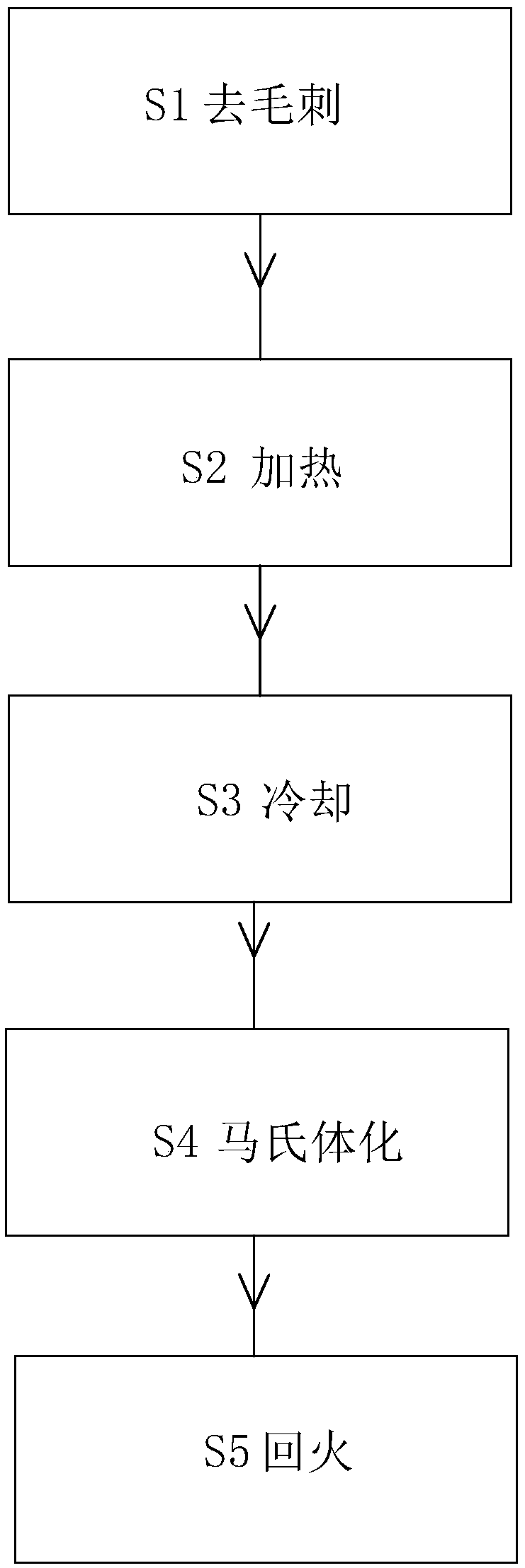

[0038] Embodiment 1: A kind of saw blade heat treatment process, refer to figure 1 , including the following steps,

[0039] S1. Deburring the circular saw blade raw material to eliminate the artificial stress concentration area and provide preliminary preparation for flattening and tempering.

[0040] S2. Put the deburred saw blade into an oven to preheat to 250°C to 400°C, and then transfer it to a heating furnace for continuous heating to 830±10°C.

[0041] S3. Make the heated saw blade stay on the furnace surface for 3 seconds, and move it to the quenching liquid surface of the quenching tank to stay for 2 to 5 seconds. After completing the stay, insert it vertically into the quenching liquid until the temperature of the saw blade drops to MS point Within the above 10°C range, then take the saw blade out of the quenching liquid; when the saw blade is immersed in the quenching liquid, stop the flow of the quenching liquid to reduce the deformation effect of the quenching l...

Embodiment 2

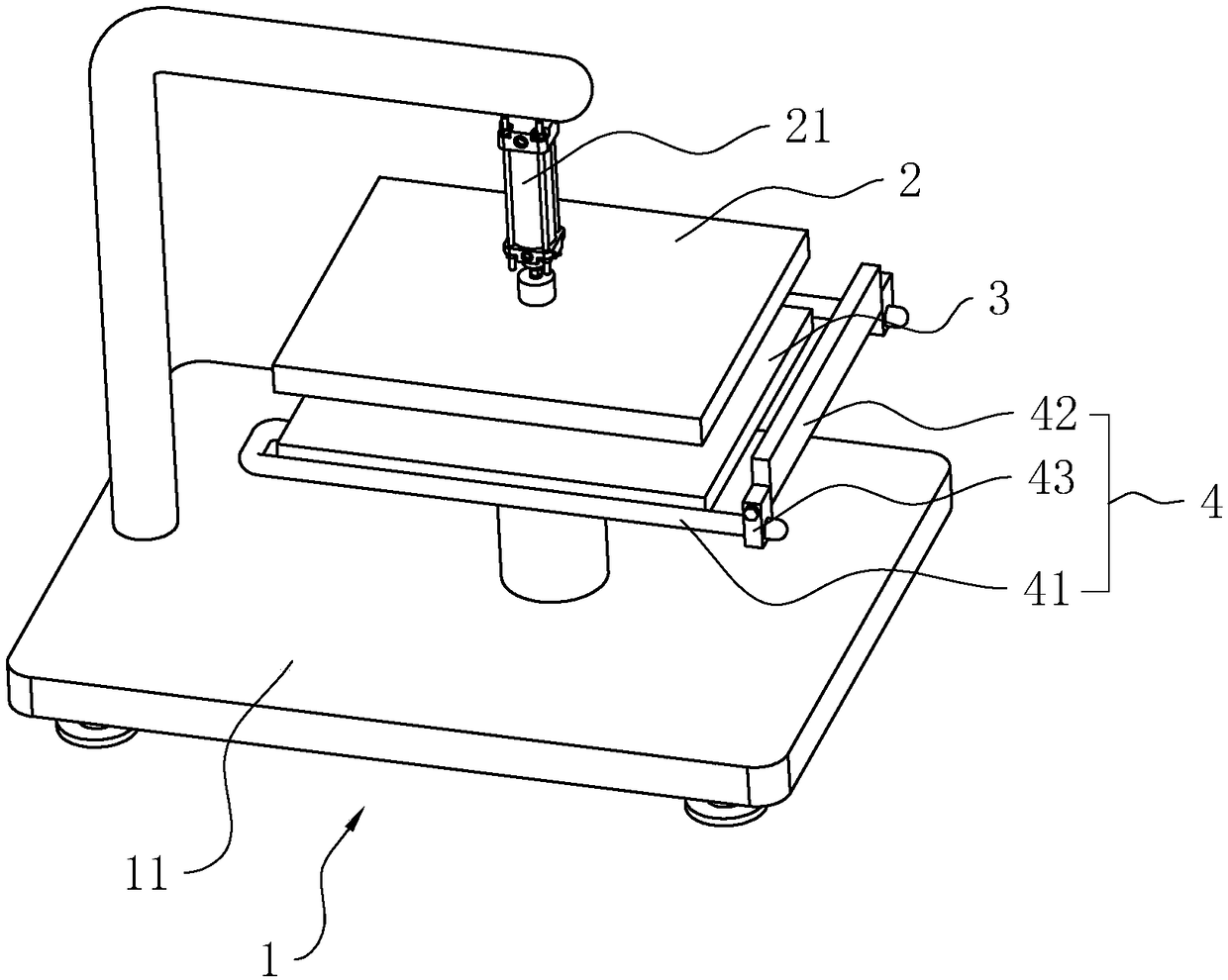

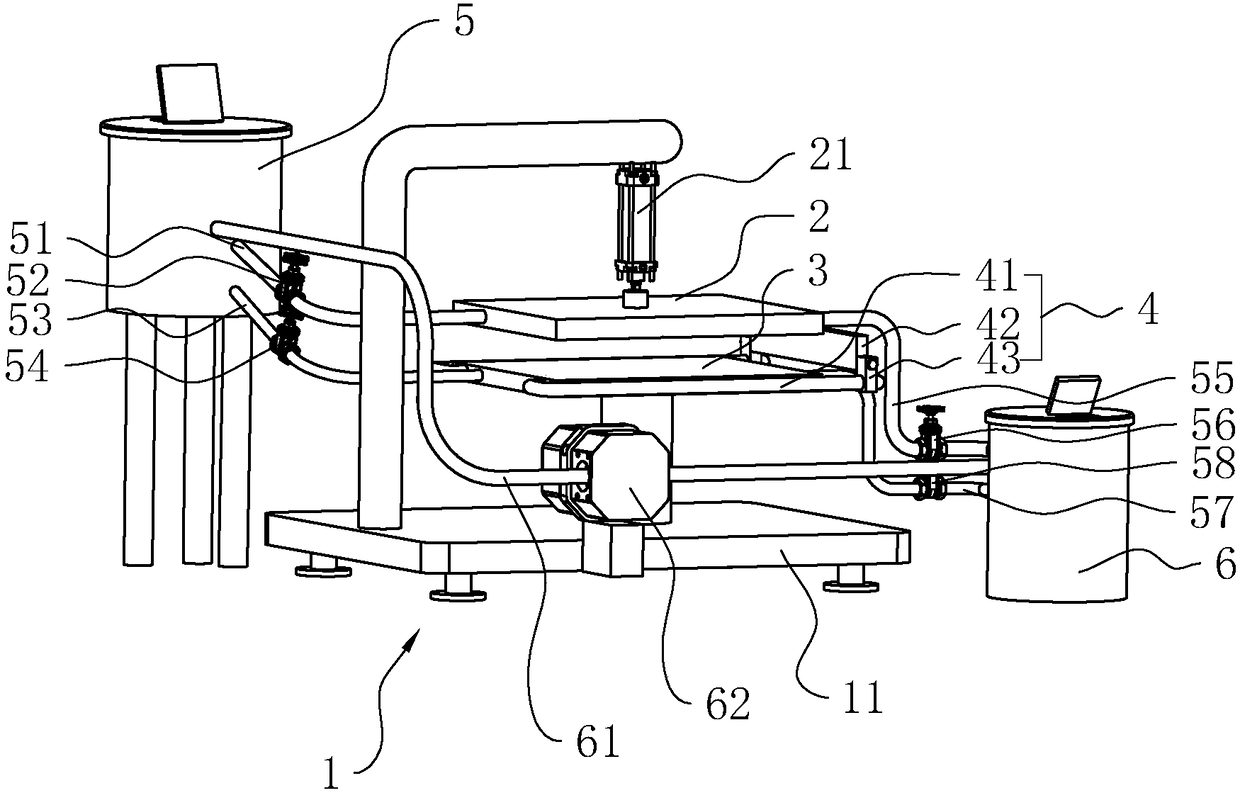

[0050] Embodiment 2: The only difference from the embodiment is that the compaction mechanism 1, refer to image 3 and Figure 4 , The pressing mechanism 1 in the present embodiment includes a frame 11 on which an upper pressing plate 2, a lower pressing plate 3, and a driver 21 for driving the upper pressing plate 2 and the lower pressing plate 3 to move relative to each other are installed. The upper platen 2 is provided with an upper liquid guide channel 22, and the side wall of the upper platen 2 is connected with an upper feed pipe 51. The upper feed pipe 51 communicates with the initial end of the upper liquid guide channel 22. The feed pipe 55 , the upper discharge pipe 55 communicates with the end of the lower liquid guiding channel 31 . The end of the upper feed pipe 51 away from the upper platen 2 is connected to the first liquid storage tank 5 , and the end of the upper discharge pipe 55 away from the upper platen 2 is connected to the second liquid storage tank 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com