Flat tube necking machine

A shrinking and flat tube technology, applied in the field of flat tube shrinking machines, can solve the problems of burning fins, product surface quality decline, flat tube surface collapse, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

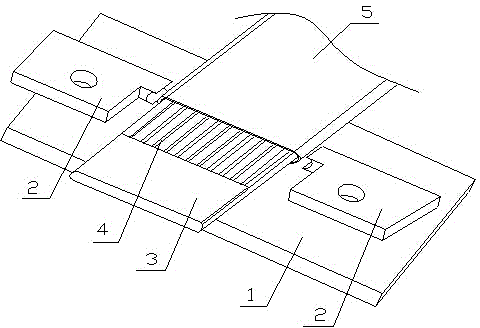

[0011] like figure 1 As shown, a flat tube necking machine includes a machine 1, a necking punch 2 arranged on the machine 1, and a steel support pin 3 is also provided on the machine 1, and the steel support pin 3 has a support pin One end of 4 is placed between the shrinking punches 2.

[0012] Put the flat tube 5 cut to length on the shrinking machine, so that the support pin 4 of the steel support pin 3 is inserted into each micropore on the flat tube 5, and then the width is narrowed, so that in the process of punching and shrinking , the tube wall cannot collapse inward due to the limitation of the support pin 4, and the outside is a cold stamping die, so it can only be thickened. In this way, a smooth necking plane is obtained, which meets the flatnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com