Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

A thermal insulation template and fiber-reinforced technology, which is applied in the direction of formwork/formwork components, walls, building components, etc., can solve the problems of low rigidity and low template strength, achieve good thermal insulation and waterproof performance, improve functional quality, and save energy. Material and Artificial Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The thickness of the fiber concrete slab is 18-22mm, and the thickness of the EPS aggregate layer is 47-52mm.

[0024] Among them, the thickness of the fiber concrete slab is 20mm, and the thickness of the EPS aggregate layer is 50mm.

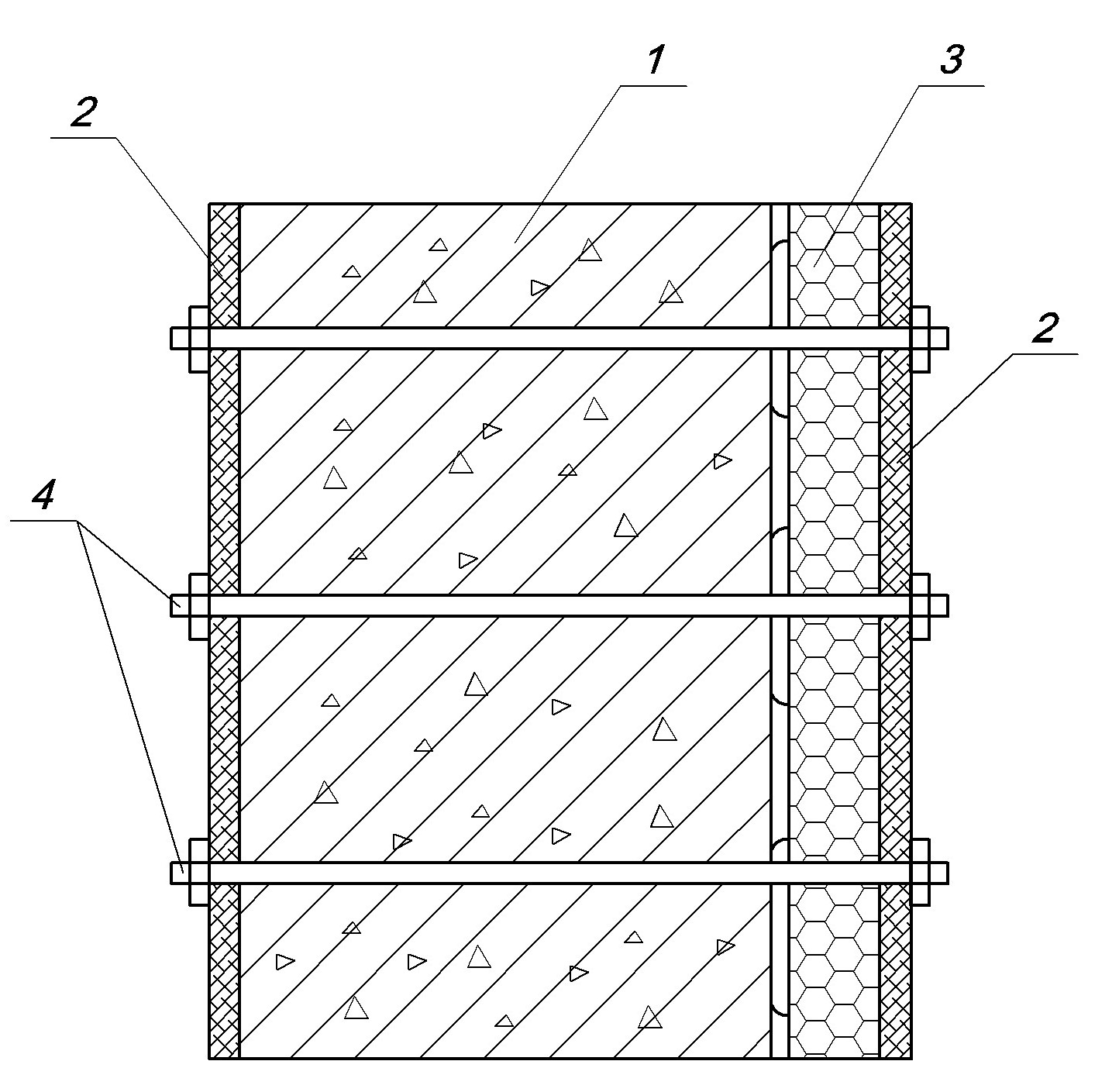

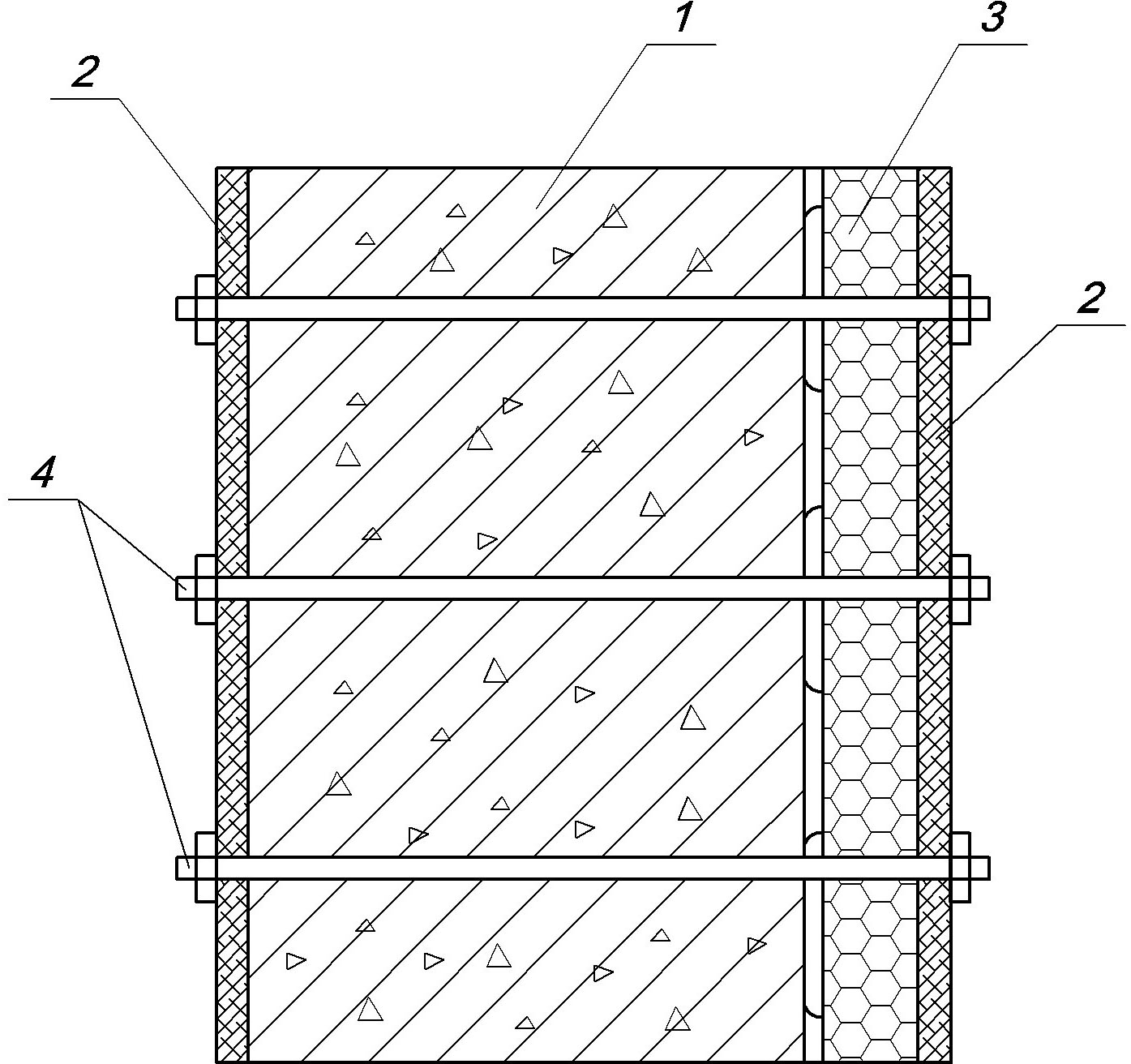

[0025] Embodiment two: see figure 1 , an exterior wall thermal insulation construction process, comprising the following steps:

Embodiment 2

[0026] (1) Prefabricated fiber concrete slabs;

[0027] (2) Prefabricate the fiber-concrete integrated thermal insulation formwork: a. First, make a fiber concrete layer at the bottom of the mold, and b. Make a layer of EPS aggregate layer on the upper side of the fiber concrete layer of the mold;

[0028] (3) On both sides of the position of the pre-built wall, the fiber concrete formwork and the fiber concrete composite insulation board are vertically fixed respectively with the thickness of the wall as the distance, and the fiber concrete formwork and the fiber concrete composite insulation board pass through Carbon fiber reinforced polymer ribs hold the bolts together.

[0029] (4) Set reinforcement between the fiber concrete formwork and fiber concrete composite insulation board and pour concrete to form a reinforced concrete load-bearing wall.

[0030] In this embodiment, the integrated thermal insulation formwork is made of industrial waste EPS particles, cement materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com