Thermal treatment method for improving low-temperature impact work of air blower main shaft

A heat treatment method and low-temperature impact technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low pass rate of heat treatment, high production cost, and inability to guarantee normal production of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

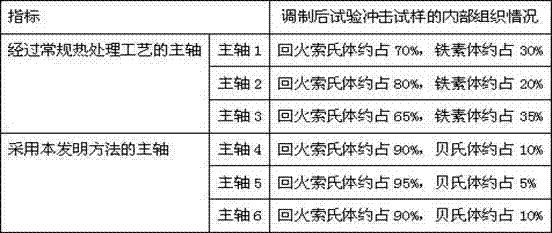

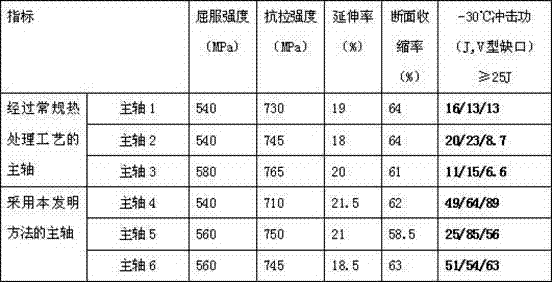

Embodiment 1

[0009] A heat treatment method for improving the low-temperature impact energy of the fan shaft. Six fan shafts made of 42CrMoA are selected, and the furnace is installed at a quenching temperature of 840°C. The heating is at an average temperature of 6-7 hours, and the furnace is released after 6-8 hours of heat preservation. The furnace temperature is 840°C. , air-cooled for 5-8 minutes and then placed in the quenching station, then sprayed with water and cooled for 2-5 minutes, then air-cooled for 1-2 minutes, then water-filled and sprayed for 10-20 minutes, then air-cooled for 2-4 minutes and then cooled by water or spraying 1 to 3 minutes, press this and repeat 3 times; after cooling, the outlet water temperature of the workpiece is controlled at 140°C, after quenching, it is tempered at a temperature of 590°C, and the tempering is kept for 25 to 30 hours; after tempering, air cooling and water cooling are alternated for 10 to 20 minutes Then air cool to room temperature. ...

Embodiment 2

[0011] A heat treatment method for improving the low-temperature impact energy of the fan shaft. Six fan shafts made of 42CrMoA are selected, and the furnace is installed at a quenching temperature of 840°C. The heating is at an average temperature of 6-7h, and the furnace is released after 6-8h of heat preservation. The furnace temperature is 860°C. ℃, air-cooled for 5-8 minutes, then placed in the quenching station, then sprayed with water to cool for 2-5 minutes, then air-cooled for 1-2 minutes, then injected with water for 10-20 minutes, then air-cooled for 2-4 minutes and then soaked in water or sprayed Cool for 1 to 3 minutes, repeat this step 4 times; after cooling, the outlet water temperature of the workpiece is controlled at 160°C, after quenching, temper at 630°C, and keep tempered for 25 to 30 hours; after tempering, air cooling and water cooling are alternated for 10 to Cool to room temperature in air after 20 min.

Embodiment 3

[0013] A heat treatment method for improving the low-temperature impact energy of the fan shaft. Six fan shafts made of 42CrMoA are selected, and the furnace is installed at a quenching temperature of 860°C. The heating is at an average temperature of 6-7 hours, and the furnace is released after 6-8 hours of heat preservation. The furnace temperature is 860°C. , air-cooled for 5-8 minutes and then placed in the quenching station, then sprayed with water and cooled for 2-5 minutes, then air-cooled for 1-2 minutes, then water-filled and sprayed for 10-20 minutes, then air-cooled for 2-4 minutes and then cooled by water or spraying 1~3min, press this and repeat 6 times; after cooling, the outlet water temperature of the workpiece is controlled at 160°C, after quenching, it is tempered at 630°C, and the tempering is kept for 25~30h; after tempering, air cooling and water cooling are alternated for 10~20min Then air cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com