Low-moisture coke quenching and waste heat utilizing device

A low-moisture, coke quenching technology, applied in steam engine installations, steam generation methods using heat carriers, coke ovens, etc. Small footprint, simple equipment structure and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

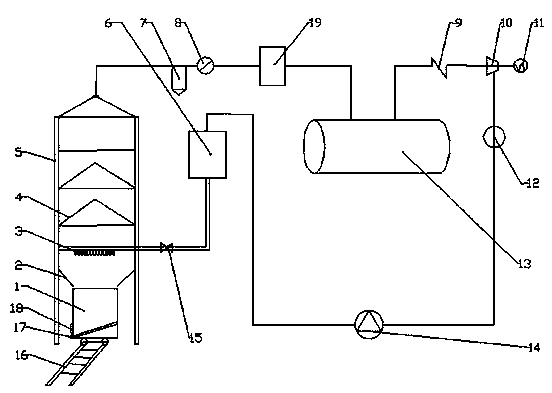

[0015] Attached below figure 1 The present invention is further described.

[0016] The present invention includes a coke quenching vehicle 1, a coke collecting hopper 2, a high-pressure water nozzle 3, a dust catcher 4, a coke quenching tower 5, a high-pressure water tank 6, a secondary dust collector 7, a purification device 8, a superheater 9, and a condensing steam turbine 10. Generator 11, condenser 12, steam heat accumulator 13, circulating water pump 14, control valve 15, guide rail 16, water outlet 17, coke outlet 18, waste heat boiler 19, among which the coke quenching tower 5 is equipped with high pressure The water nozzle 3 and the coke collection bucket 2 are equipped with a dust collector 4 on the upper part. The top pipe is connected to the waste heat boiler 19 and the steam accumulator 13 through the secondary dust collector 7 and the purification device 8, and then connected to the condensing steam through the superheater 9. type steam turbine 10, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com