Carbon steel sheet having excellent carburization properties, and method for producing same

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve the problems of not seeing the process and technology not being disclosed

Active Publication Date: 2011-08-10

NIPPON STEEL CORP

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] Regarding the production conditions of the B-containing steel sheet, Patent Document 1 discloses that annealing is performed in a hydrogen atmosphere or an Ar atmosphere with the nitrogen content suppressed to 10% by volume or less, but there is no mention of the processes before and after the annealing.

In addition, the technology considering the carburizing treatment under the low-carbon potential targeted by the present invention has not been disclosed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0120] The present invention will be described based on examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

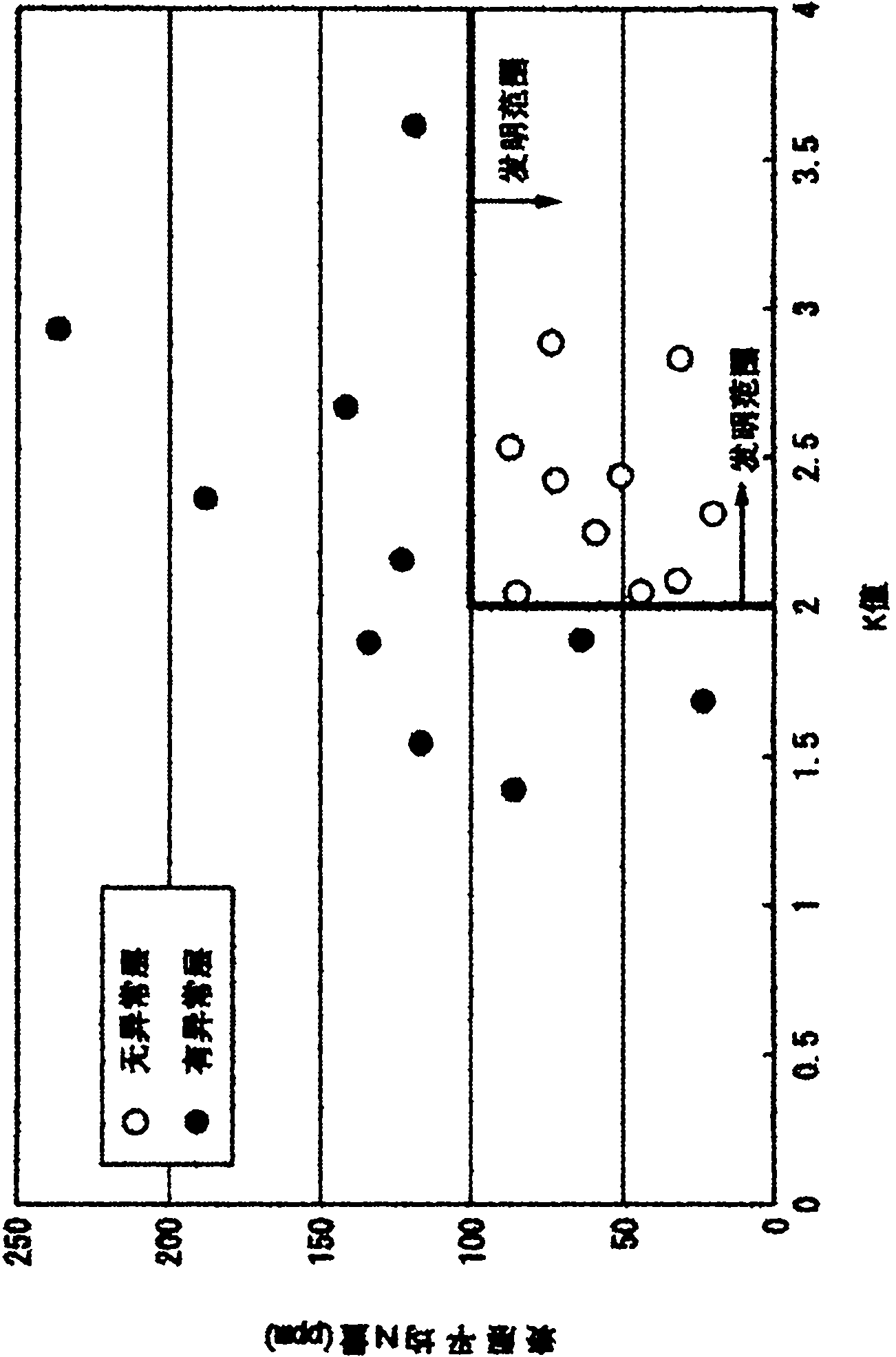

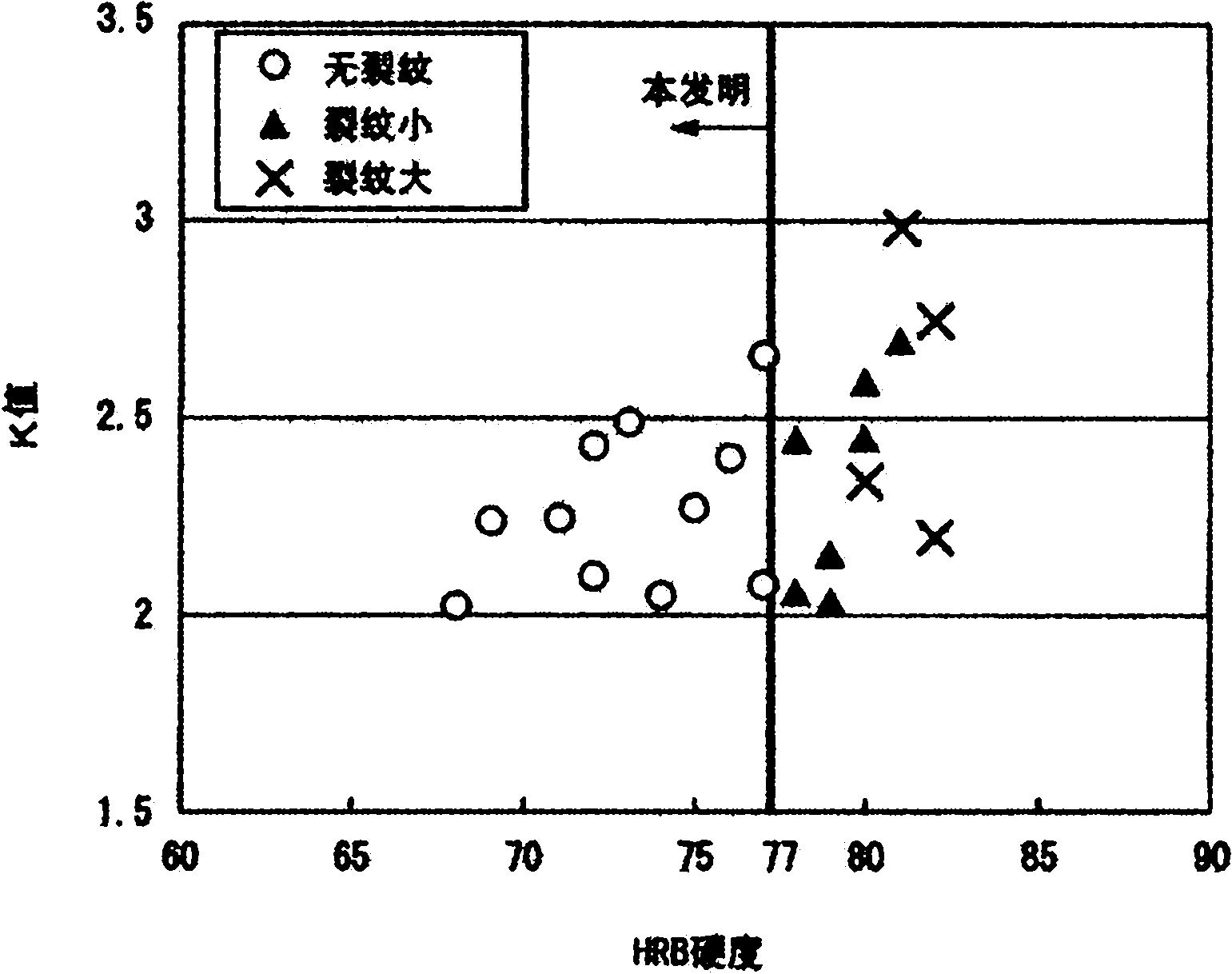

Disclosed is a carbon steel sheet which contains not less than 0.20% by mass but not more than 0.45% by mass of C, not less than 0.05% by mass but not more than 0.8% by mass of Si, not less than 0.85% by mass but not more than 2.0% by mass of Mn, not less than 0.001% by mass but not more than 0.04% by mass of P, not less than 0.0001% by mass but not more than 0.006% by mass of S, not less than 0.01% by mass but not more than 0.1% by mass of Al, not less than 0.005% by mass but not more than 0.3% by mass of Ti, not less than 0.0005% by mass but not more than 0.01% by mass of B, and not less than 0.001% by mass but not more than 0.01% by mass of N. The carbon steel sheet has a K value, which is expressed by 3C + Mn + 0.5Si, of not less than 2.0, a surface hardness, namely a Rockwell hardness of not more than 77 on the B scale, and an average N content of not more than 100 ppm in the region from the surface to the depth of 100 [mu]m. The carbon steel sheet is carburized in a carburizing atmosphere having a carbon potential of not more than 0.6.

Description

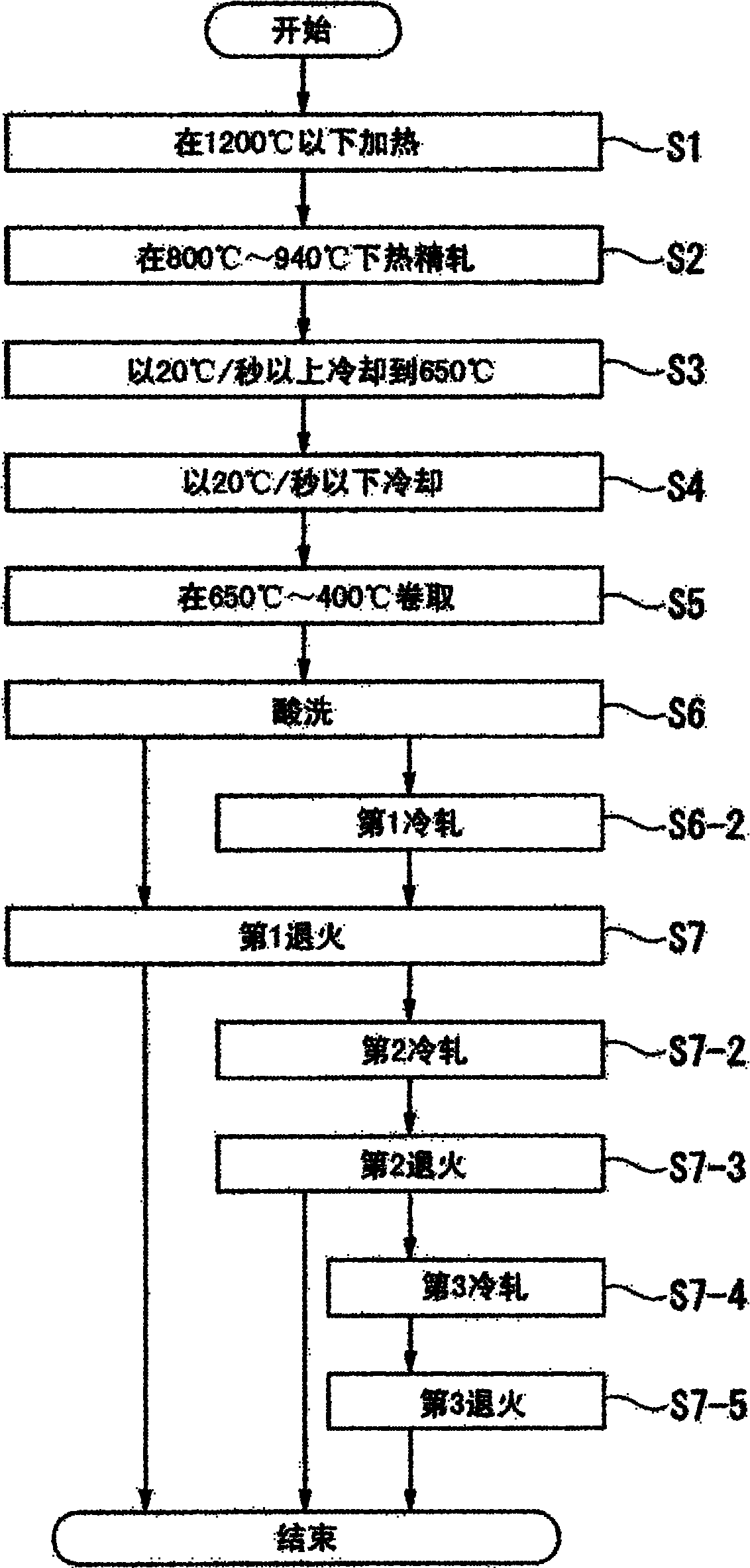

technical field [0001] The present invention relates to a carbon steel sheet excellent in carburizing and hardenability and a method for producing the same. [0002] This application claims priority based on Japanese Patent Application No. 2009-079959 for which it applied in Japan on March 27, 2009, and uses the content here. Background technique [0003] Conventionally, automotive parts such as chain parts, gear parts, and clutch parts, or industrial machine parts, have been produced by hardening the surface by heat treatment such as quenching after forming. [0004] However, in recent years, in addition to complicating the shape of parts, wear resistance and fatigue characteristics are required for the parts themselves. Therefore, not only workability to withstand complex machining when processed into parts is required for the billet, but also hardenability for surface hardening is required. The so-called hardenability and workability of the billet are opposite character...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/00C21D1/06C21D9/46C22C38/14C22C38/60

CPCC21D8/0268C22C38/32C21D8/0263C21D1/06C22C38/14C22C38/04C21D9/46C22C38/001C21D8/0236C22C38/18C21D8/0426C21D8/0226C22C38/02C23C8/22C22C38/42C21D8/0436C22C38/06C21D8/0468C21D8/0463C21D9/561C22C38/40C22C38/008C22C38/44

Inventor 阿部雅之竹田健悟矢头久齐

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com