Heat treatment technique for bolts

A bolt and process technology, applied in the field of heat treatment of bolts, can solve problems such as insufficient hardness in the quenched state, uneven hardness in the quenched state, decarburization of the bolt surface, etc., and achieve the effects of good quenching effect, improved quality, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

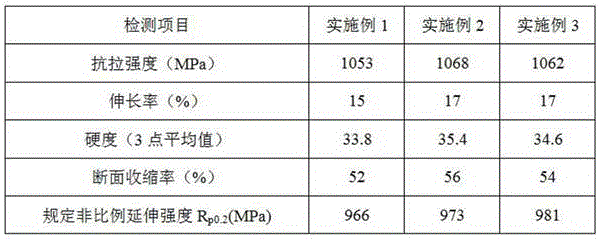

Examples

Embodiment 1

[0022] The heat treatment process of bolts includes the following steps:

[0023] S1. Phosphorus removal: Put the product into the washing machine and pour the cleaning solution until the product is completely immersed in the cleaning solution. Adjust the cleaning temperature to 40°C and stir once every 15 minutes. After cleaning for 2 hours, take the product out and put it away. Dephosphorization treatment is carried out in the dephosphorization tank;

[0024] The cleaning solution is composed of the following components in parts by mass: 20 parts of butyl acetate, 10 parts of polyglycolic acid, 16 parts of aminoacetic acid, 13 parts of ethyl acrylate, 5 parts of oleic acid triethanolamine salt, 3 parts of ethanolamine and 18 parts of water; The dephosphorization tank is equipped with a dephosphorization solution, and the dephosphorization solution is a potassium hydroxide solution with a concentration of 2.2g / L;

[0025] S2. Pretreatment: put the product into the preheating...

Embodiment 2

[0032] The present embodiment is identical with the processing step in embodiment 1, and difference is specific processing condition, comprises the following steps:

[0033] S1. Dephosphorization: Put the product into the washing machine, and pour the cleaning solution until the product is completely immersed in the cleaning solution. Adjust the cleaning temperature to 50°C, stir once every 15 minutes, and take out the product after cleaning for 3 hours. Dephosphorization treatment is carried out in the dephosphorization tank;

[0034] The cleaning solution is composed of the following components in parts by mass: 36 parts of butyl acetate, 13 parts of polyglycolic acid, 20 parts of aminoacetic acid, 22 parts of ethyl acrylate, 9 parts of triethanolamine oleic acid, 16 parts of ethanolamine and 26 parts of water; The dephosphorization tank is equipped with a dephosphorization solution, and the dephosphorization solution is a potassium hydroxide solution with a concentration of...

Embodiment 3

[0042] The present embodiment is identical with the processing step in embodiment 1, and difference is specific processing condition, comprises the following steps:

[0043] S1. Dephosphorization: Put the product into the washing machine, and pour the cleaning solution until the product is completely immersed in the cleaning solution. Adjust the cleaning temperature to 45°C, stir once every 15 minutes, and take out the product after cleaning for 2.5 hours. Put it in the dephosphorization tank for dephosphorization treatment;

[0044] The cleaning solution is composed of the following components in parts by mass: 28 parts of butyl acetate, 12 parts of polyglycolic acid, 18 parts of aminoacetic acid, 18 parts of ethyl acrylate, 7 parts of triethanolamine oleic acid, 10 parts of ethanolamine and 22 parts of water; The dephosphorization tank is equipped with a dephosphorization solution, and the dephosphorization solution is a sodium hydroxide solution with a concentration of 4.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com