Process for production of 780mpa-grade high-tensile-strength steel plates excellent in low-temperature toughness

A technology of low-temperature toughness and manufacturing method, which is applied in the field of manufacturing 780MPa grade high-tensile steel plate, and can solve the problems of toughness deterioration and unproposed manufacturing method of high-tensile steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

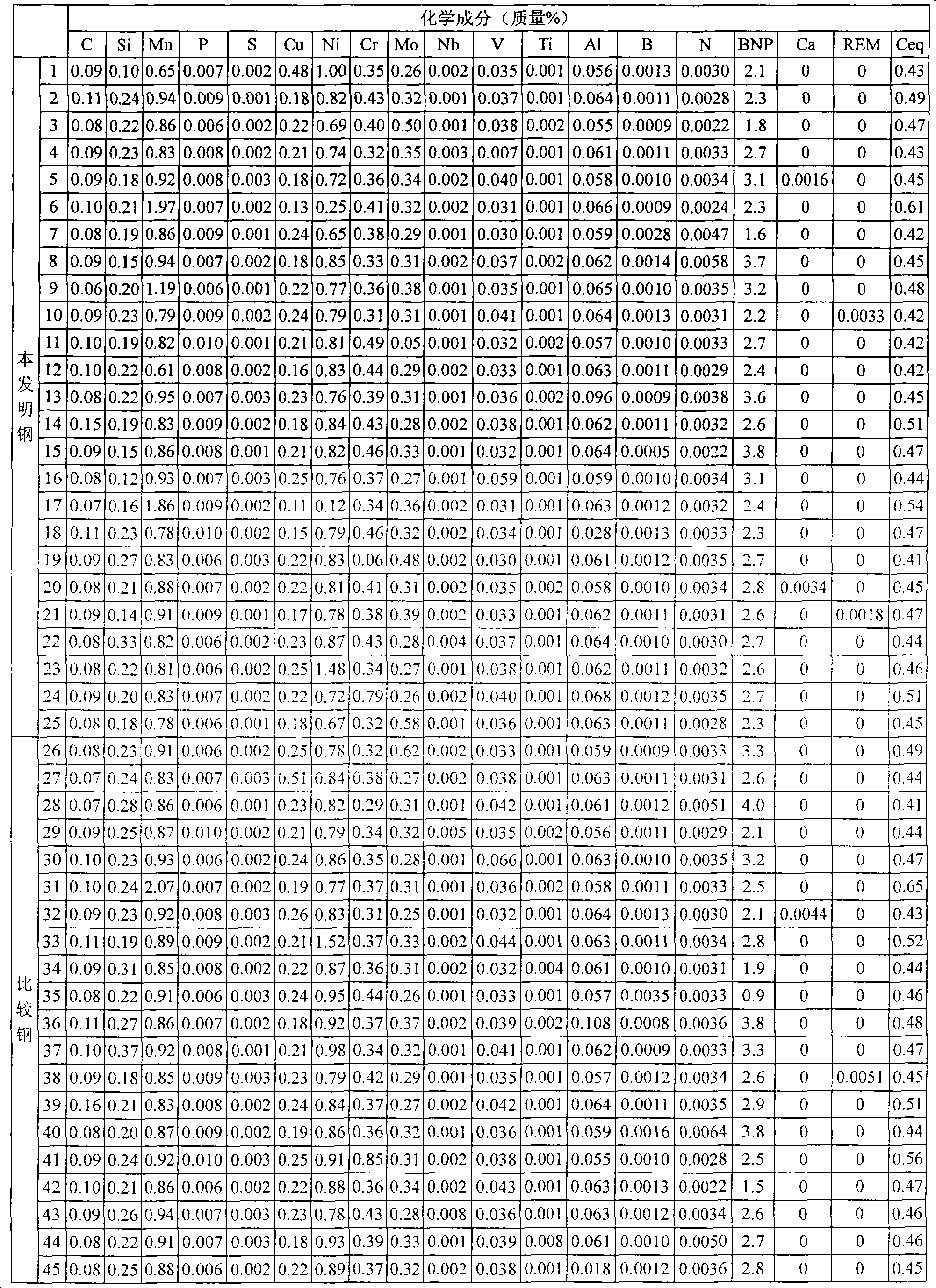

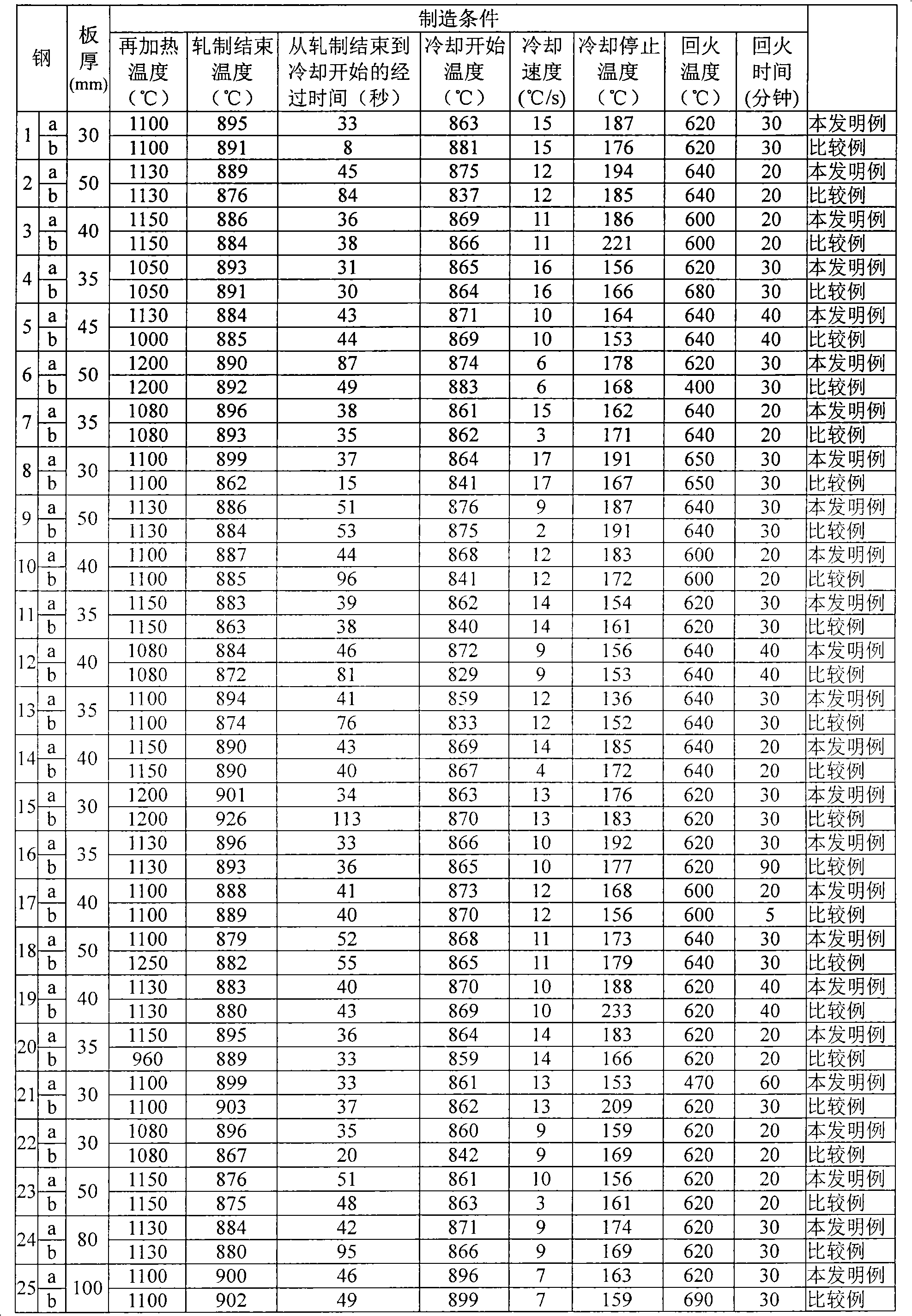

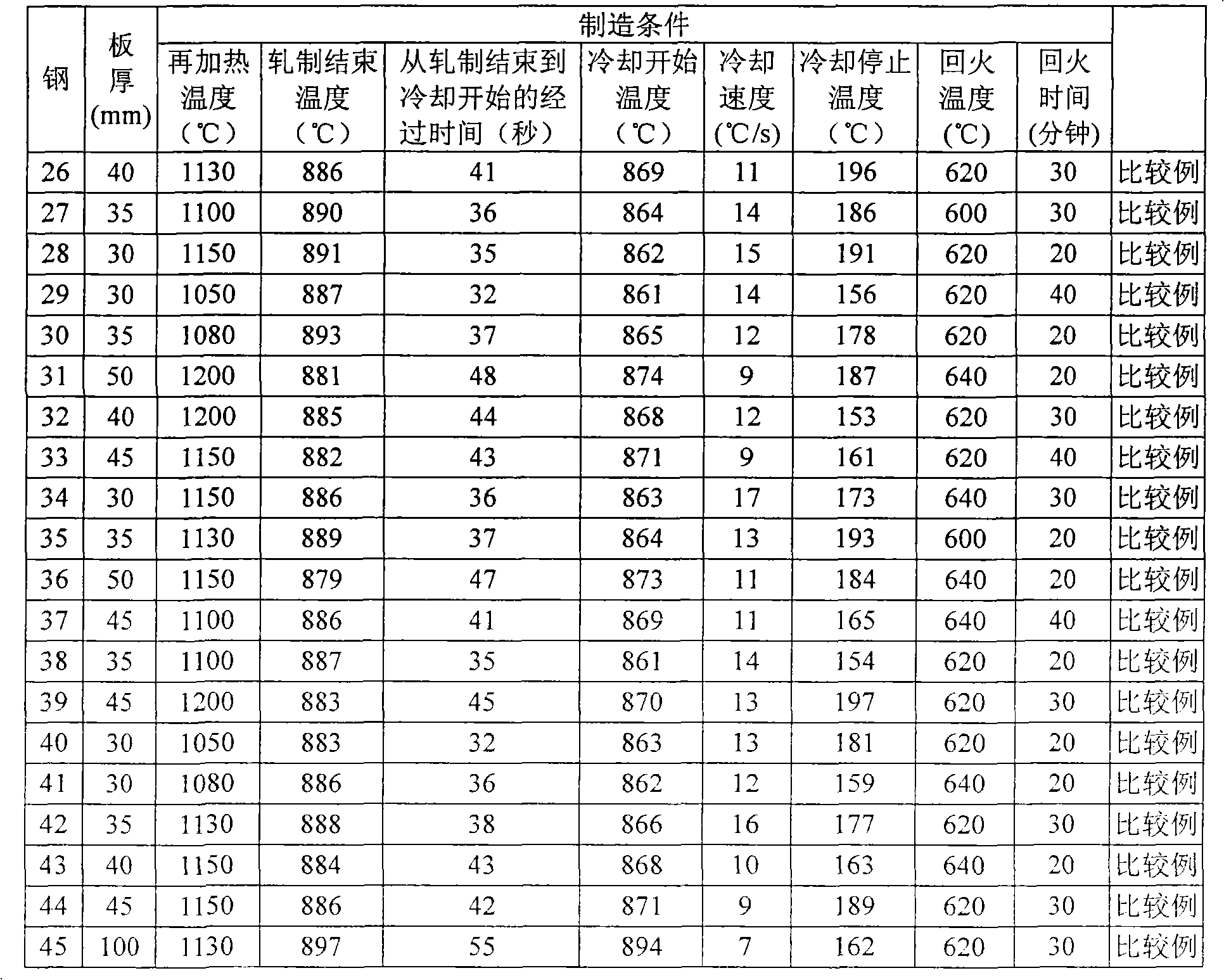

[0071] Next, examples of the present invention will be discussed.

[0072] Slabs having the chemical compositions in Table 1 were subjected to hot rolling and tempering under the conditions shown in Table 2 and Table 3, and after forming steel sheets, tests were carried out to evaluate mechanical properties. As tensile test pieces, JIS No. 4 test pieces were taken from 1 / 4 and 1 / 2 of the plate thickness of each steel plate, and YS (0.2% proof strength), TS, and El were evaluated. Regarding the toughness of the base material, JIS 2 mm V notch test pieces were taken from the 1 / 4 and 1 / 2 parts of the plate thickness of each steel plate, and the Charpy impact test was performed at -40°C, and the impact absorbed energy value obtained was evaluated. In addition, regarding HAZ toughness, steel materials subjected to a reproducible heat cycle test with a welding input energy of 5 kJ / mm were evaluated based on the impact absorbed energy value obtained from the Charpy impact test at -40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com