High-strength steel sheet for can manufacturing and process for manufaturing the sheet

A manufacturing method and high-strength technology, applied in manufacturing tools, furnace types, furnaces, etc., can solve the problems of increasing martensite particle size, inability to take into account strength and ductility, etc., to improve hardenability, strength, and high strength. and ductility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

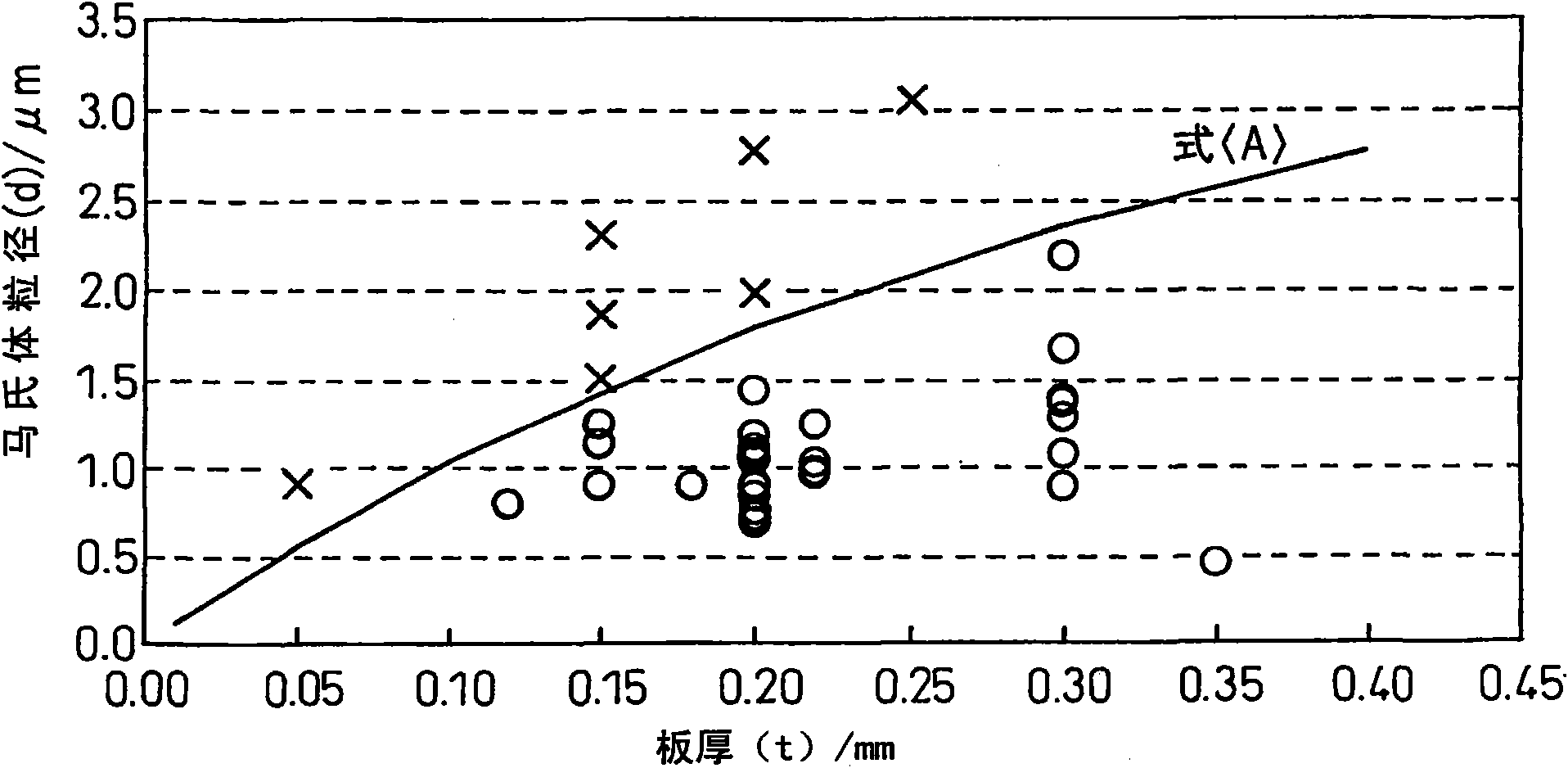

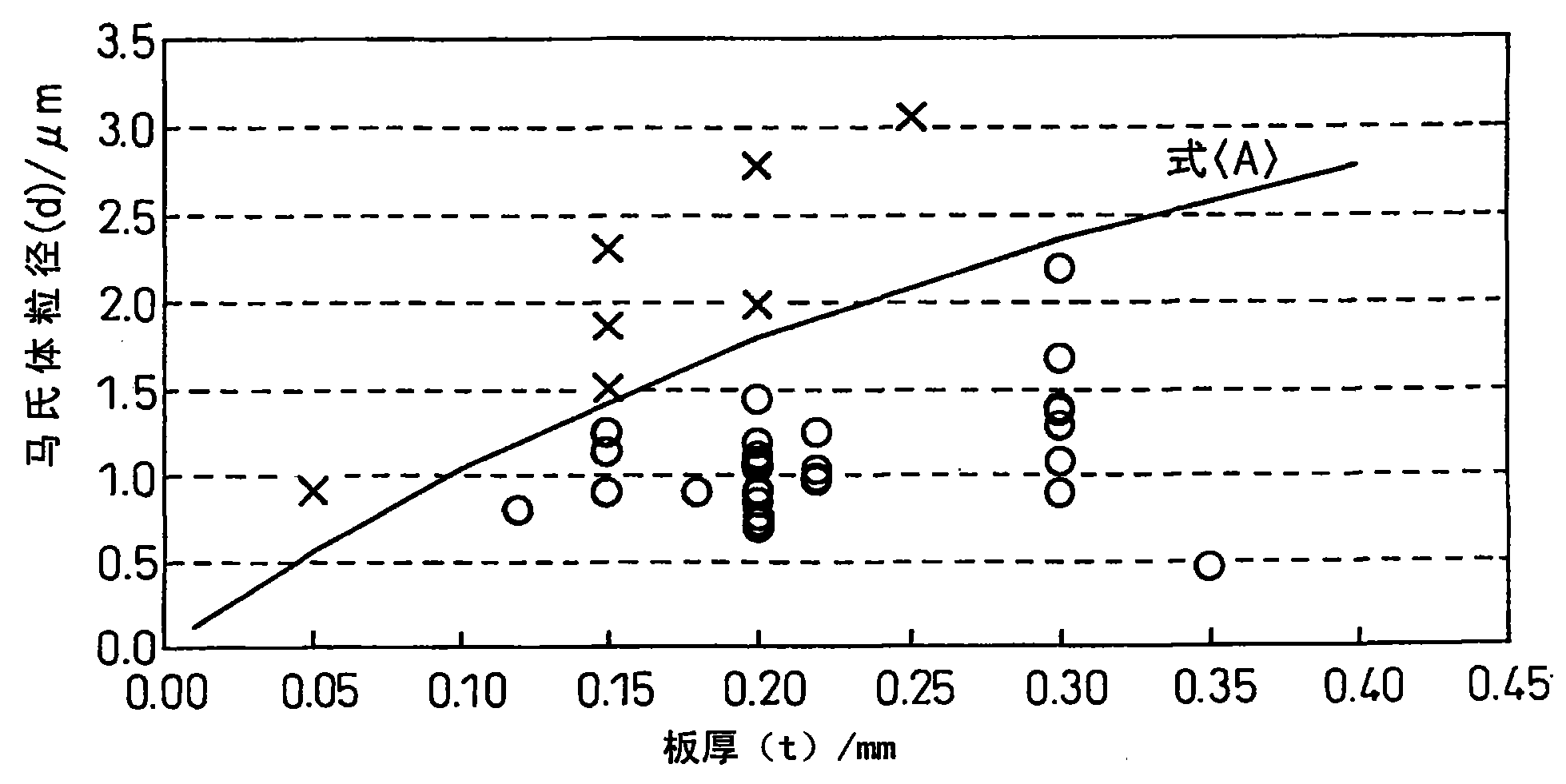

[0069] The steel with the composition shown in Table 1 was smelted, and for the steel plates A1-S1 manufactured under the manufacturing conditions shown in Table 2 and Table 3 (continued from Table 2), the state of martensite, the formula The calculation results on the left, 30T hardness, and elongation were evaluated.

[0070]

[0071]

[0072]

[0073] Here, regarding the state of martensite, the martensite was identified by LePera (レペラ-) etching, and image analysis was carried out on at least 100 fields of view with a field of view of 0.2 μm × 0.2 μm with a 1000-magnification optical microscope to obtain Martensite fraction (the area ratio of martensite in the structure). In addition, regarding the martensite grain size, the circle-equivalent diameter was calculated by the same measurement and averaged.

[0074] About hardness, it evaluated based on 30T of JISZ2245. If the 30T hardness is less than 60, the strength is insufficient when used for the...

Embodiment 2

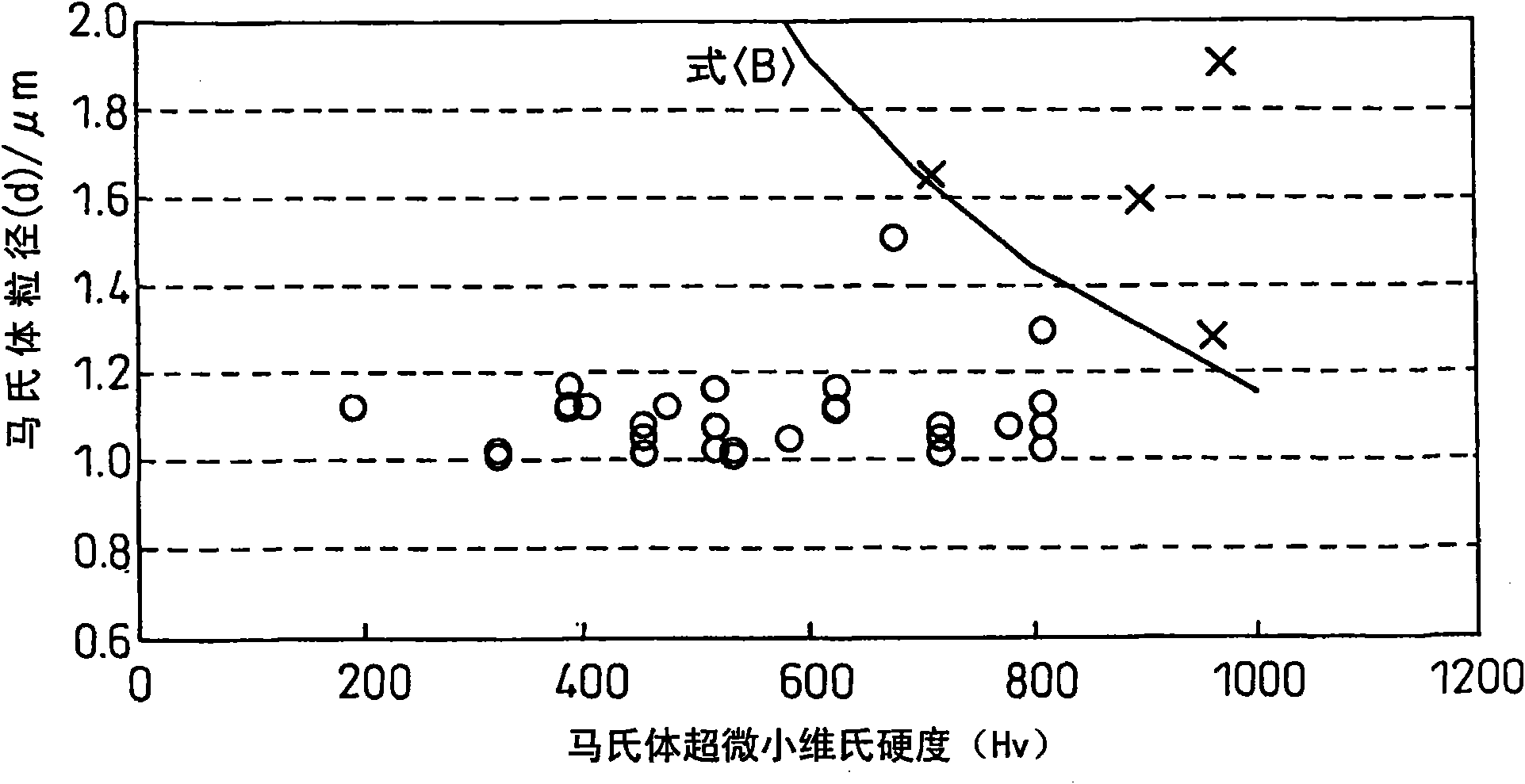

[0077] Under the manufacturing conditions shown in Table 4 and Table 5 (continued from Table 4), the steel with the composition shown in Table 1 was made into steel plates A21~Q22, and the martensitic state of the steel plate, formula The calculation results on the left, martensite ultra-fine Vickers hardness, 30T hardness, and elongation were evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com