Method for controlling water cooling process of quenching machine

A process control, quenching machine technology, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve problems such as drop, long water spray time, unstable water pressure in low pressure area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] figure 1 , figure 2 It is an embodiment of the present invention.

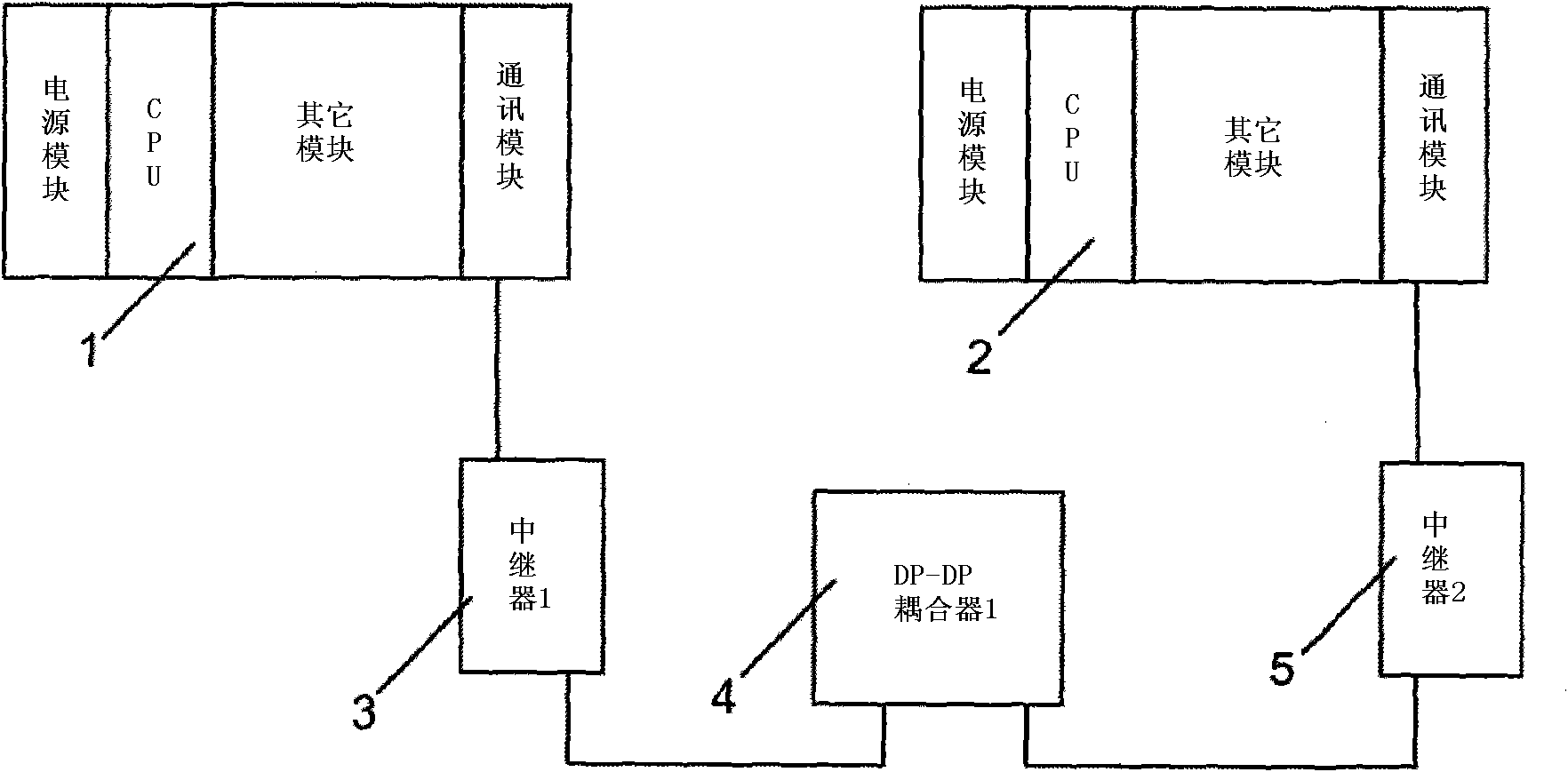

[0021] like figure 1 As shown, add a DP-DP coupler 4, pass it through figure 1 The idle channels of DP network repeater 3 and DP network repeater 5 in the network are connected to PROFIBUS-DP network, so that figure 1 The steel plate tracking PLC1 and the quenching machine PLC2 can exchange data.

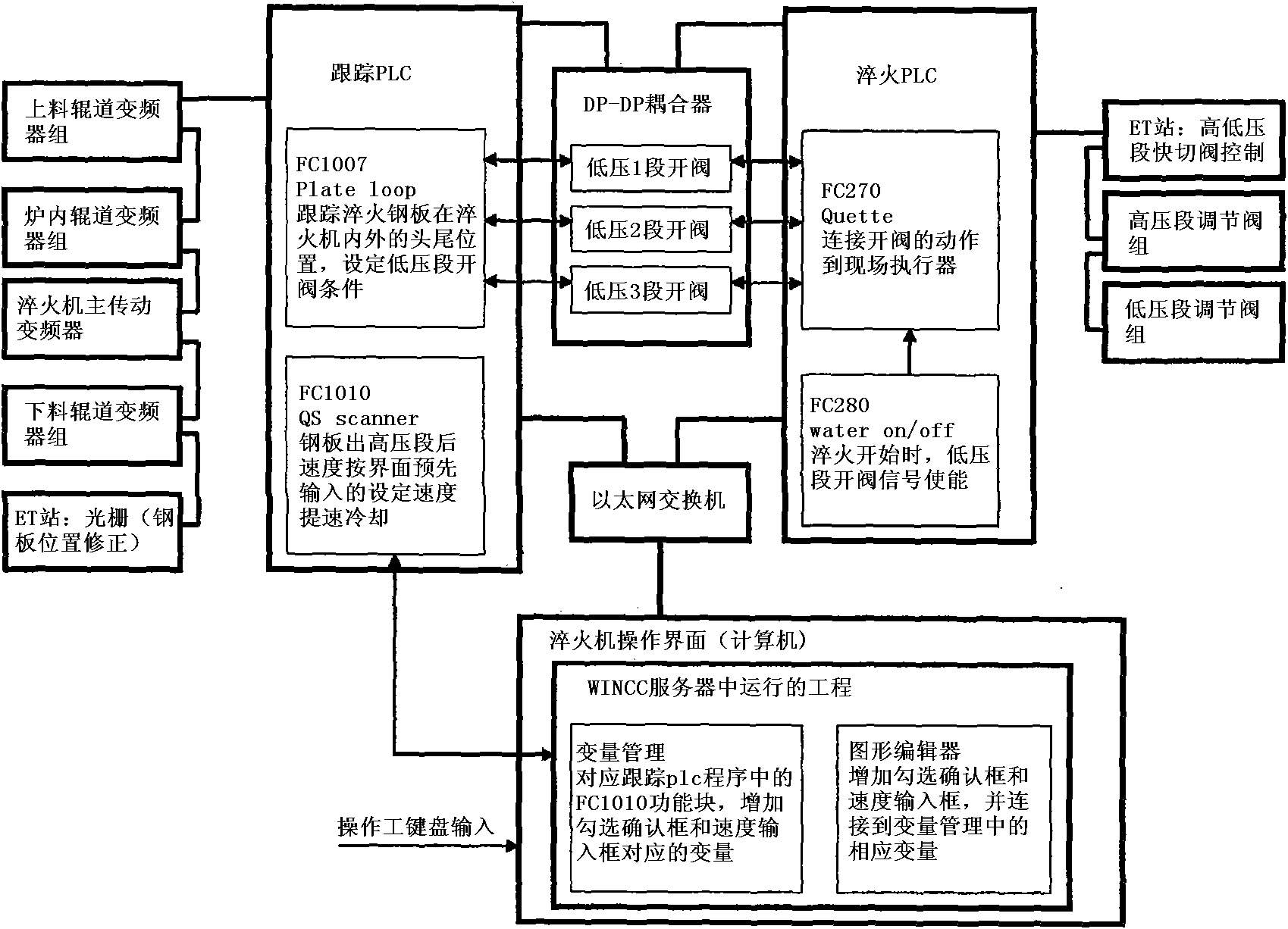

[0022] figure 2 It is the modified functional flowchart of the program. The external thick line frame is the hardware part, including PLC, DP-DP coupler, computer operation interface and field equipment controlled by PLC (roller table inverter group, regulating valve, ET station and its next-level grating and fast cutting valve) . The thin line frame contained in the thick line frame of the outer layer is the modified PLC program function block, the main chain point added and the modified WINCC project. The connecting wires without arrows between wire frames include profibus-dp network cables for da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com