Necking process method and necking tool for titanium alloy self-locking nut

A technology of self-locking nut and process method, applied in nuts, metal processing equipment, forming tools, etc., can solve the problems of deformation of thread cracking at the end, and achieve the effect of eliminating processing stress, improving safety, and avoiding the possibility of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The -5 specification titanium alloy self-locking nut prepared by machining was subjected to solution treatment, the solution temperature was 940°C, kept for 30 minutes, and then water-cooled to room temperature to obtain a sample for closing processing.

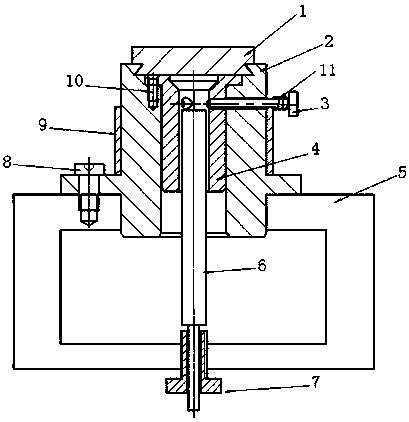

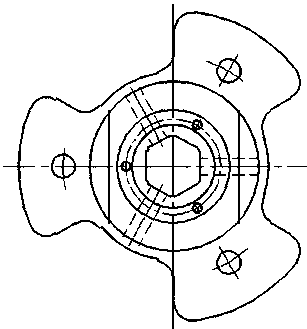

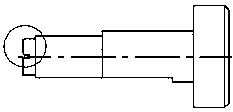

[0036] use as figure 1 The hexagonal width of the closing mold core 4 should be 0.05mm larger than the hexagonal width of the nut. The closing mold core 4 is put into the closing mold base 2, and positioning pin 10 is used for positioning, so that the three Ø5 holes evenly distributed on the side of the closing mold core 4 are concentric with the three Ø5 holes of the closing mold base 2 to ensure the closing. 3 can smoothly pass through the closing mold base 2 and the closing mold core 4, and then contact with the sample to be closed. Put the anti-rotation sleeve 9 on the closing mold base 2, and the closing push pin 3 equipped with the spring 11 passes through the hole, and its lower plane should be in contact with ...

Embodiment 2

[0039] The -8 specification titanium alloy self-locking nut prepared by machining was subjected to solution treatment, the solution temperature was 950 ° C, kept for 40 minutes, and then water-cooled to room temperature to obtain a sample for closing processing.

[0040] use as figure 1 The hexagonal width of the closing mold core 4 should be 0.10mm larger than the hexagonal width of the nut. The closing mold core 4 is put into the closing mold base 2, and positioning pin 10 is used for positioning, so that the three Ø5 holes evenly distributed on the side of the closing mold core 4 are concentric with the three Ø5 holes of the closing mold base 2 to ensure the closing. 3 can pass through the closing mold base 2 and the mold core smoothly, and then contact with the sample to be closed. Put the anti-rotation sleeve 9 on the closing mold base 2, and the closing push pin 3 equipped with the spring 11 passes through the hole, and its lower plane should be in contact with the uppe...

Embodiment 3

[0043] The -12 specification titanium alloy self-locking nut prepared by machining was subjected to solution treatment, the solution temperature was 970°C, kept for 60 minutes, and then water-cooled to room temperature to obtain a sample for closing processing.

[0044] use as figure 1 The hexagonal width of the closing mold core 4 should be 0.15mm larger than the hexagonal width of the nut. The closing mold core 4 is put into the closing mold base 2, and positioning pin 10 is used for positioning, so that the three Ø5 holes evenly distributed on the side of the closing mold core 4 are concentric with the three Ø5 holes of the closing mold base 2 to ensure the closing. 3 can pass through the closing mold base 2 and the mold core smoothly, and then contact with the sample to be closed. Put the anti-rotation sleeve 9 on the closing mold base 2, and the closing push pin 3 equipped with the spring 11 passes through the hole, and its lower plane should be in contact with the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com