Heat treatment technology for reducing deformation of spiral bevel gear for industrial robot

A technology of industrial robots and bevel gears, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as low yield, large deformation, and inability to guarantee consistent product performance, achieve hardness without soft spots, and eliminate processing stress , Appearance without variegated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

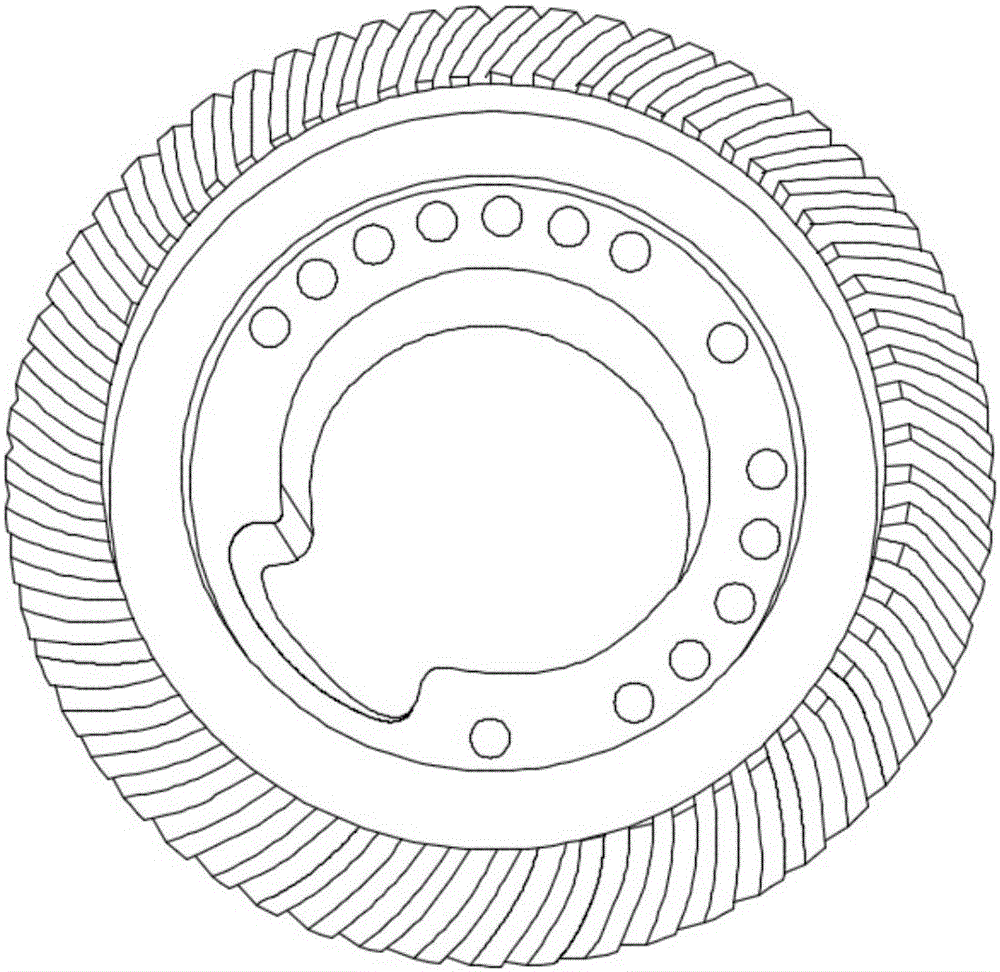

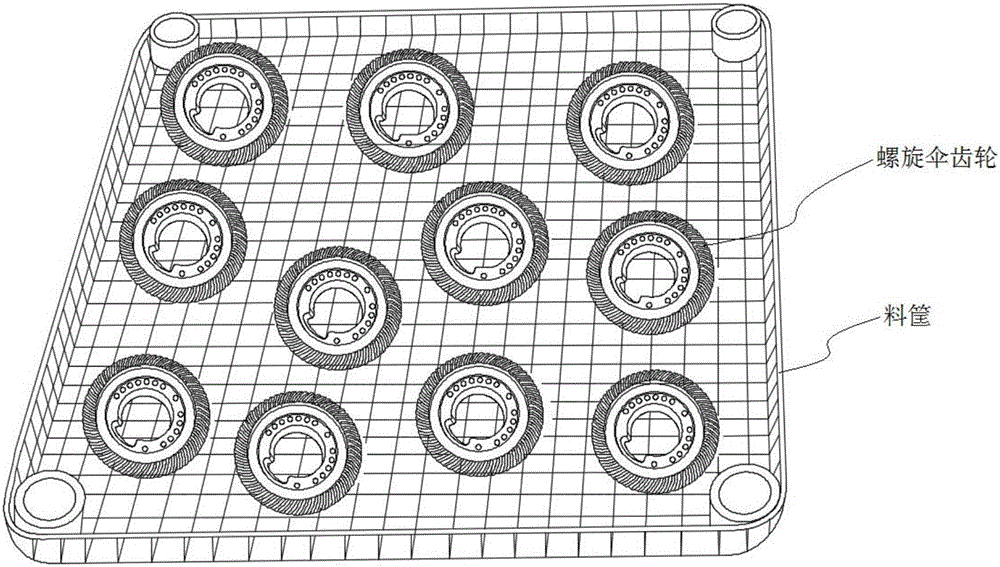

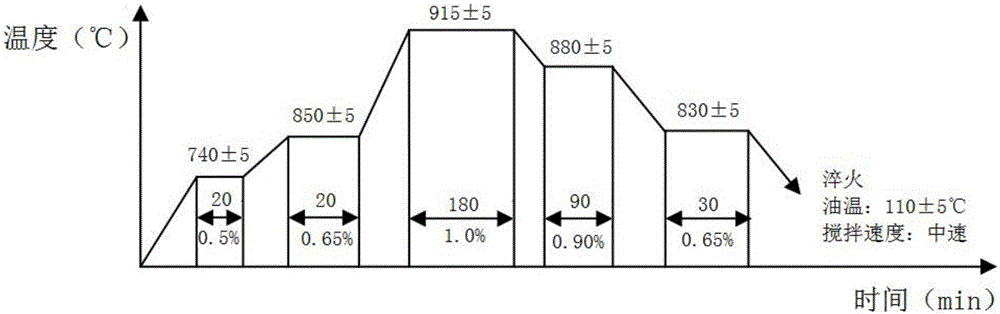

[0040] Taking the heat treatment process of a spiral bevel gear for an industrial robot with a modulus of 2.12 and a number of teeth of 60 as an example, the technical requirements for heat treatment are: surface hardness is 60-63HRC, effective hardened layer depth is 0.5-0.8mm, and the beating of ribs≤ 0.018mm (runout of ribs before heat treatment ≤ 0.01mm), deformation of inner hole ≤ 0.015mm (deformation of inner hole before heat treatment ≤ 0.008mm). In order to meet the above heat treatment requirements, a heat treatment process for reducing the deformation of the industrial robot spiral bevel gear in this embodiment includes the following steps:

[0041](1) Parts preparation: Carry out high-temperature normalizing treatment on the alloy steel billet of the brand SCM420, so that the surface hardness of the billet can reach 170-190HBW, and uniform ferrite and pearlite structures can be obtained. The preparatory heat treatment of the billet will not only affect its cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com