Method for welding thick aluminum alloy plate

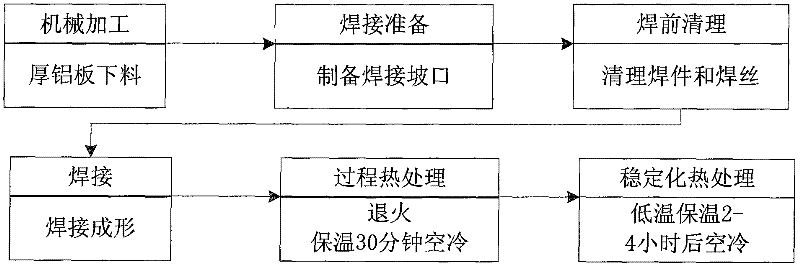

A welding method and aluminum alloy technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of difficult control of welding deformation and low connection strength, and achieve the elimination of welding residual stress and improve mechanical properties , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

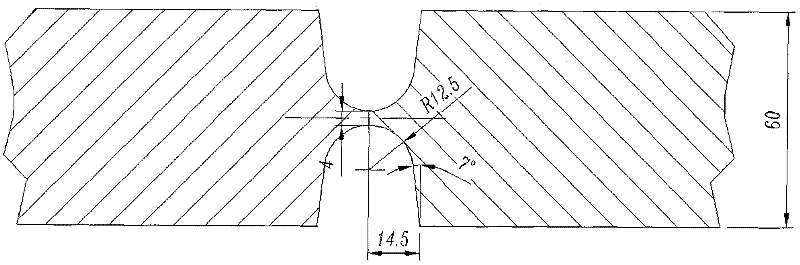

[0042] The box-type hanging frame made of Al-Mg 5A06-H112 aluminum alloy plate is tailor-welded from aluminum alloy plates with a width of about 200mm and a plate thickness of about 60mm. The frame is 1m square and large in size. Dimensional accuracy requires ±0.5mm.

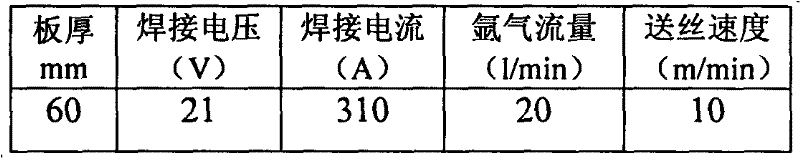

[0043] The welding of the box-type hanging frame adopts Miganic Flex 5000 melting electrode argon arc welding machine equipment, and the two ends of the aluminum plate to be welded are fixed and welded firmly by means of internal support and external pressure. The welding parameters are shown in Table 2.

[0044] Table 25A06 (60mm) MIG welding process parameters

[0045]

[0046] Conduct X-ray flaw detection on the welded joints, and evaluate the welds in accordance with QJ176A-99 "General Technical Conditions for Fusion Welding of Ground Equipment" to meet the requirements of Class I welds.

[0047] Necessary heat treatment for the welded box-type hanging frame can effectively reduce stress. After welding...

example 2

[0049] The box-type hanging frame made of Al-Mg 5A06-H112 aluminum alloy thick plate is tailor-welded from aluminum alloy plates with a width of about 220mm and a plate thickness of about 65mm. The frame is 1.2m square and large in size. Dimensional accuracy requires ±0.5mm.

[0050] The welding of the box-type hanging frame adopts Miganic Flex 5000 melting electrode argon arc welding machine equipment, and the two ends of the aluminum plate to be welded are fixed and welded firmly by means of internal support and external pressure. The welding parameters are shown in Table 3.

[0051] Table 35A06 (65mm) MIG welding process parameters

[0052]

[0053] Conduct X-ray flaw detection on the welded joints, and evaluate the welds in accordance with QJ176A-99 "General Technical Conditions for Fusion Welding of Ground Equipment" to meet the requirements of Class I welds.

[0054] Necessary heat treatment for the welded box-type hanging frame can effectively reduce stress. After...

example 3

[0056] The box-type hanging frame made of Al-Mg 5A06-H112 aluminum alloy thick plate is tailor-welded from aluminum alloy plates with a width of about 180mm and a thickness of about 55mm. The frame is 0.9m square and large in size. Dimensional accuracy requires ±0.5mm.

[0057] The welding of the box-type hanging frame adopts Miganic Flex 5000 melting electrode argon arc welding machine equipment, and the two ends of the aluminum plate to be welded are fixed and welded firmly by means of internal support and external pressure. The welding parameters are shown in Table 4.

[0058] Table 45A06 (55mm) MIG welding process parameters

[0059]

[0060] Conduct X-ray flaw detection on the welded joints, and evaluate the welds in accordance with QJ176A-99 "General Technical Conditions for Fusion Welding of Ground Equipment" to meet the requirements of Class I welds.

[0061] Necessary heat treatment for the welded box-type hanging frame can effectively reduce stress. After weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com