Speed reducer output end sealing structure and RV speed reducer composed of same

A technology of sealing structure and output end, which is applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc. It can solve the problems of shortened service life of glue, oil leakage, and inability to guarantee the sealing effect, so as to improve the service life of the seal and reduce the sealing effect. Difficulty of operation, effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

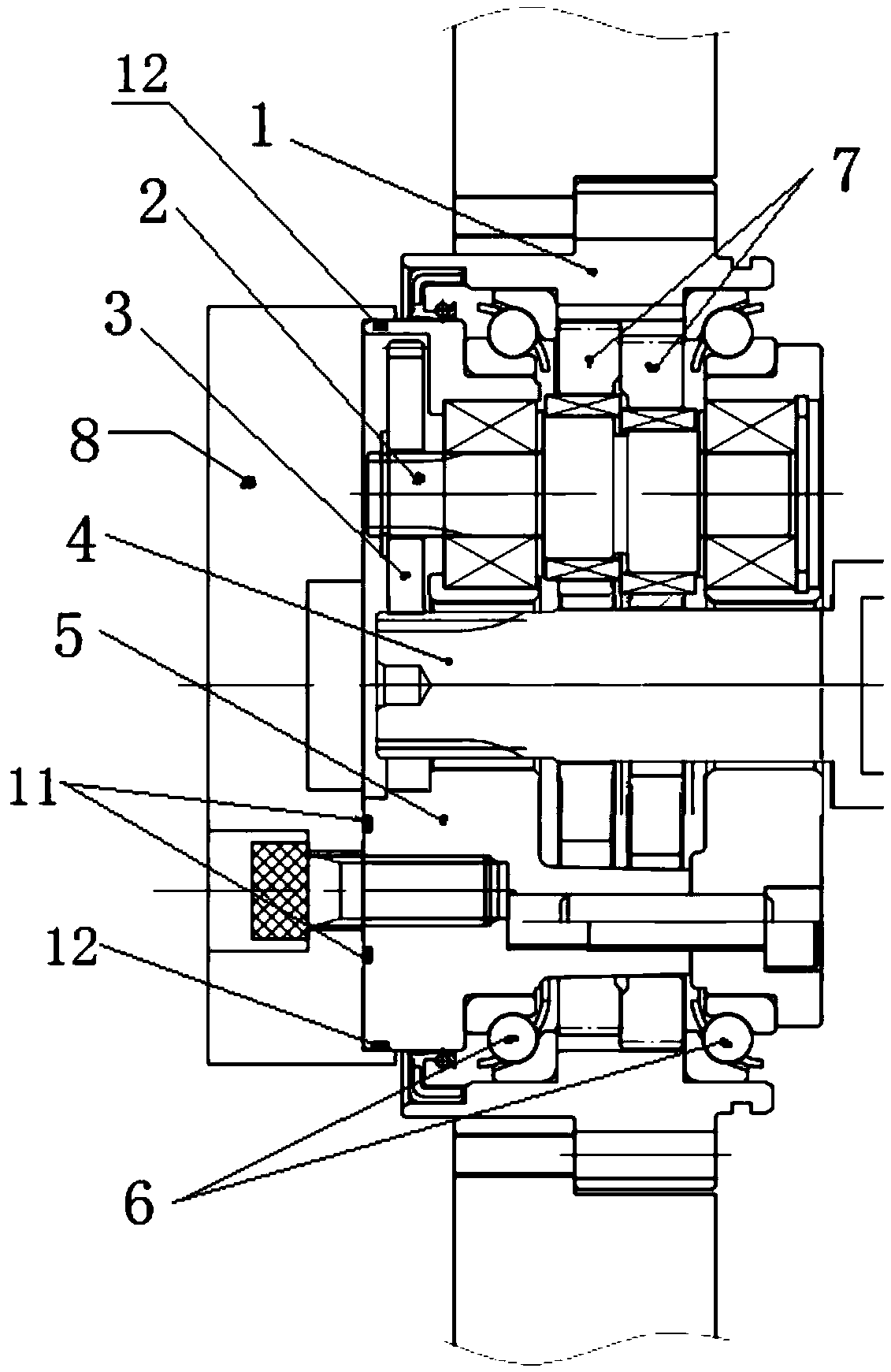

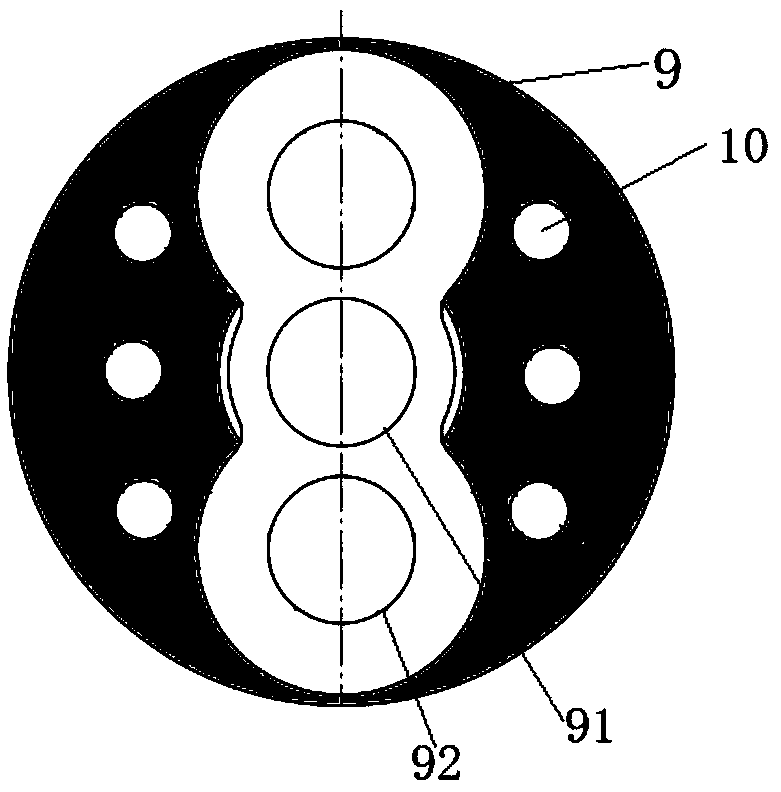

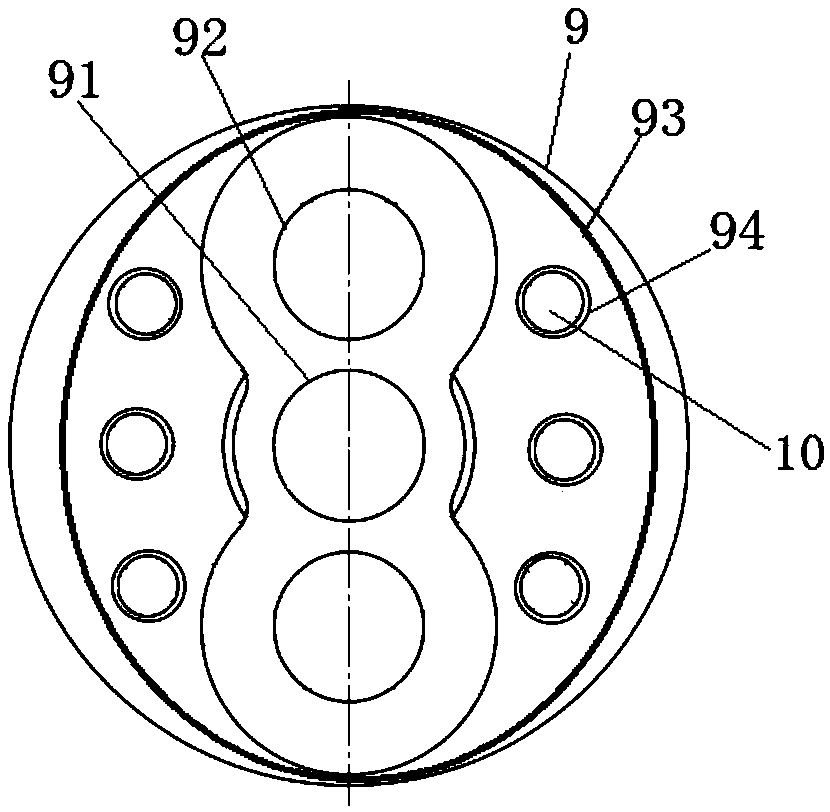

[0035] Such as figure 1 As shown, a sealing structure at the output end of a reducer includes an output end flange 8 and an output frame 5 connected to the reducer; the output frame 5 has a smooth output end face 9, and the center of the output end face 9 has a sun gear groove 91 And the planetary gear grooves 92 distributed axially symmetrically or annularly around the sun gear groove; the output end face 9 also has a threaded hole 10 for fixing the output disc frame 5, and the output end face 9 penetrates into the inside of the output end face flange 8 and is connected with the output The end flange 8 forms a face or line seal.

[0036] Such as figure 2 As shown, according to the sealing requirements, the black part in the figure is required to be sealed with the output end face flange 8, but the black part has a narrow edge, and it is required to apply neither too much nor too little glue, so the operation is extremely demanding, and The effect of sealing is not very ideal...

Embodiment 2

[0039] Such as figure 1 As shown, a sealing structure at the output end of a reducer includes an output end flange 8 and an output frame 5 connected to the reducer; the output frame 5 has a smooth output end face 9, and the center of the output end face 9 has a sun gear groove 91 And the planetary gear grooves 92 distributed axially symmetrically or annularly around the sun gear groove; the output end face 9 also has a threaded hole 10 for fixing the output disc frame 5, and the output end face 9 penetrates into the inside of the output end face flange 8 and is connected with the output The end flange 8 forms a face or line seal.

[0040] In this embodiment, at least one O-ring groove is formed on the outer wall of the output disk frame 5 on the output end face 9 in the radial direction, and the inner wall of the O-ring groove is provided for sealing the inner wall of the flange 8 on the output end face. The O-ring 12 on the outer wall of the output end surface 9 outputs the ...

Embodiment 3

[0044] Such as figure 1 As shown, an RV reducer with the sealing structure of the output end of the above-mentioned embodiment 1 or embodiment 2 includes a pin gear housing 1, an eccentric shaft 2, a planetary wheel 3, an input shaft 4, an output disc frame 5, and angular contact balls Bearing 6, cycloidal wheel 7, output end flange 8; planetary gear 3 is installed on one end of eccentric shaft 2; input shaft 4 is located in the center of pin gear housing 1, and the end gear of input shaft 4 and planetary gear 3 rotate at the same time Mesh connection on the plane constitutes the first-stage planetary deceleration mechanism; cycloid wheel 7, pin gear housing 1, and needle roller constitute the second-stage cycloid deceleration mechanism.

[0045] In addition, the eccentric shaft 2 of the RV reducer includes two cams 13, the axis lines of the two cams 13 are parallel to each other, and are symmetrically distributed on both sides of the main axis of the eccentric shaft 2 at 180°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com