RV precise speed reducer eccentric shaft and precise speed reducer

A precision reducer and eccentric shaft technology, which is applied in the direction of eccentric shafts, mechanical equipment, engine components, etc., can solve the problems of poor precision of reducers, poor fatigue resistance and impact resistance, and short life of eccentric shafts, so as to improve the load capacity , Load capacity and anti-fatigue ability are strengthened, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

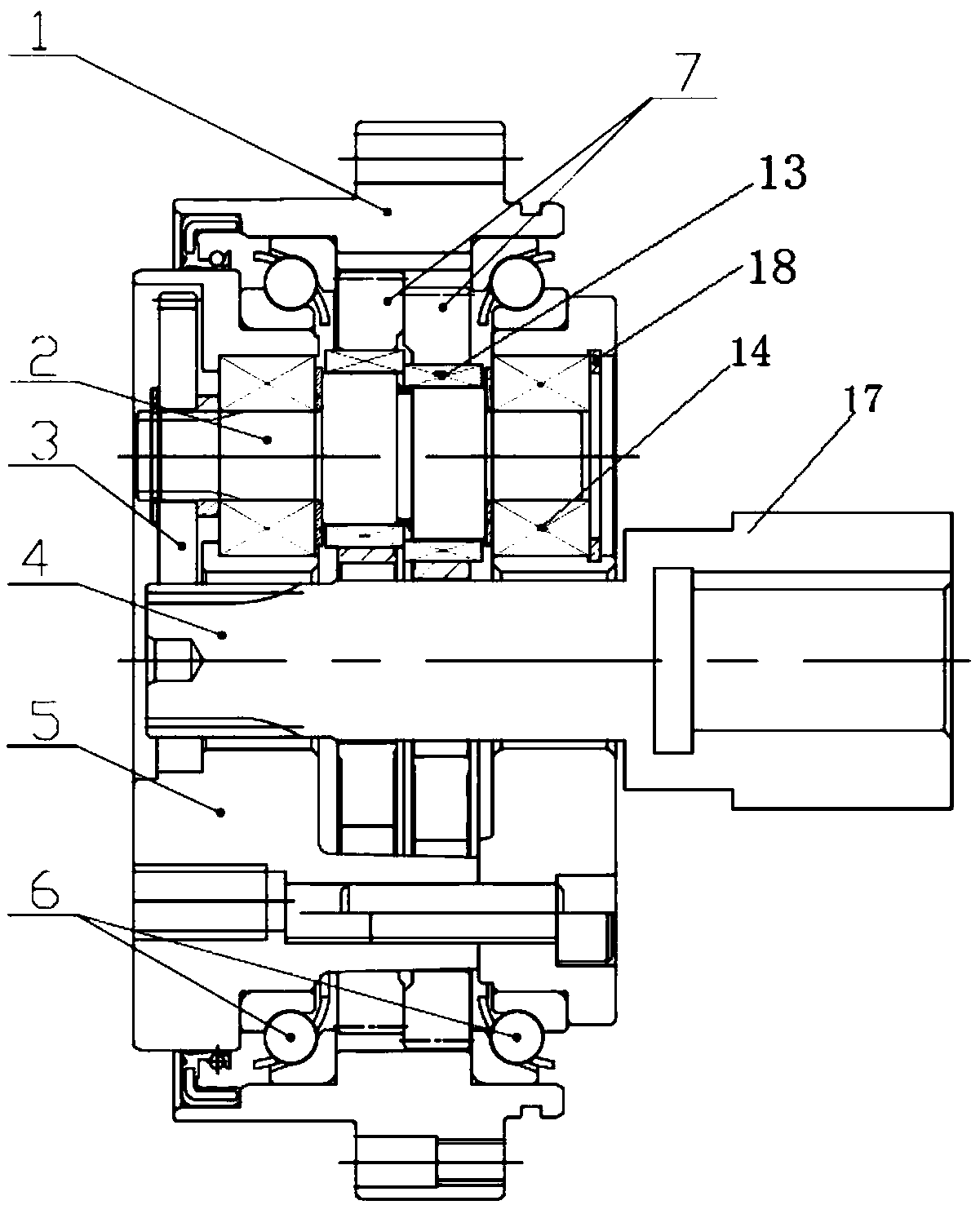

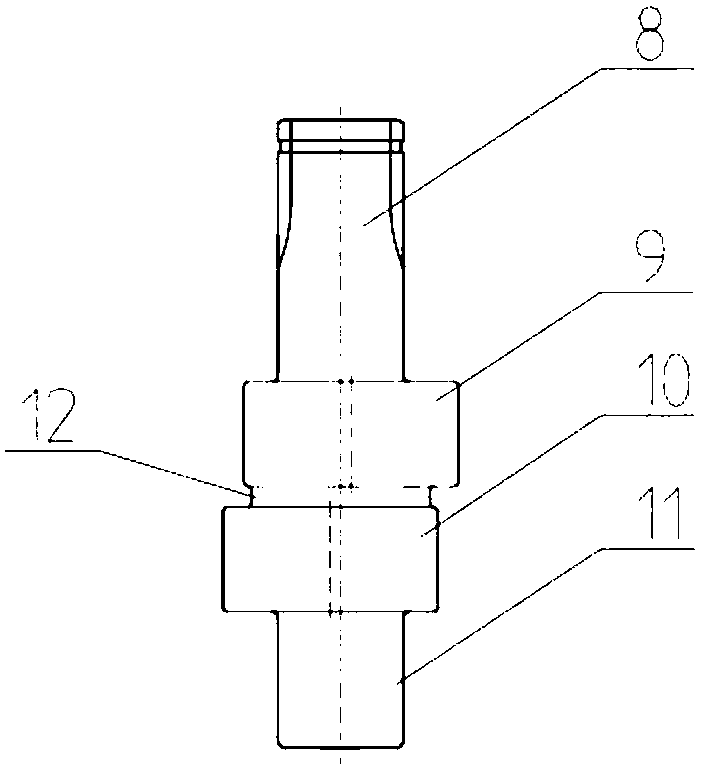

[0032] Such as figure 1As shown, an eccentric shaft of an RV precision reducer and a precision reducer are characterized in that the precision reducer includes a pin gear housing 1, an eccentric shaft 2, a planetary wheel 3, an input shaft 4, an output frame 5, and an angular contact ball bearing 6. Cycloidal wheel 7; planetary gear 3 is installed on one end of eccentric shaft 2; input shaft 4 is located in the center of pin gear housing 1, one end of input shaft 4 is connected with motor 17, and the other end is a central gear, which is connected to the The planetary gears 3 are meshed and connected on the same rotation plane to form the first-stage planetary reduction mechanism; the cycloidal wheel 7, pin gear housing 1, and needle rollers constitute the second-stage cycloidal reduction mechanism; the first-stage planetary reduction mechanism and the second-stage pendulum The linear deceleration mechanism is connected together through an eccentric shaft to transmit speed and...

Embodiment 2

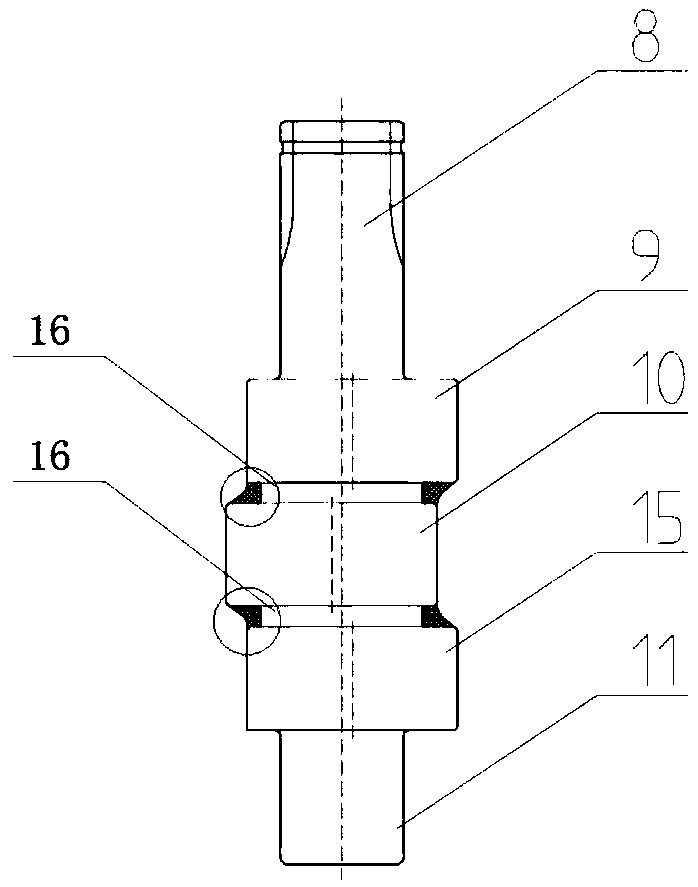

[0040] Such as Figure 7 As shown, an eccentric shaft of an RV precision reducer and a precision reducer are characterized in that the precision reducer includes a pin gear housing 1, an eccentric shaft 2, a planetary wheel 3, an input shaft 4, an output frame 5, and an angular contact ball bearing 6. Cycloidal wheel 7; planetary gear 3 is installed on one end of eccentric shaft 2; input shaft 4 is located in the center of pin gear housing 1, one end of input shaft 4 is connected with motor 17, and the other end is a central gear, which is connected to the The planetary gears 3 are meshed and connected on the same rotation plane to form the first-stage planetary reduction mechanism; the cycloidal wheel 7, pin gear housing 1, and needle rollers constitute the second-stage cycloidal reduction mechanism; the first-stage planetary reduction mechanism and the second-stage pendulum The linear deceleration mechanism is connected together through an eccentric shaft to transmit speed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com