Forming process of nickel-based bimetal composite tube

A technology of bimetallic composite pipe and metal outer pipe, applied in the direction of furnace types, manufacturing tools, furnaces, etc., can solve the problems of high cost and low efficiency, and achieve the effect of low cost, high efficiency and strengthened solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

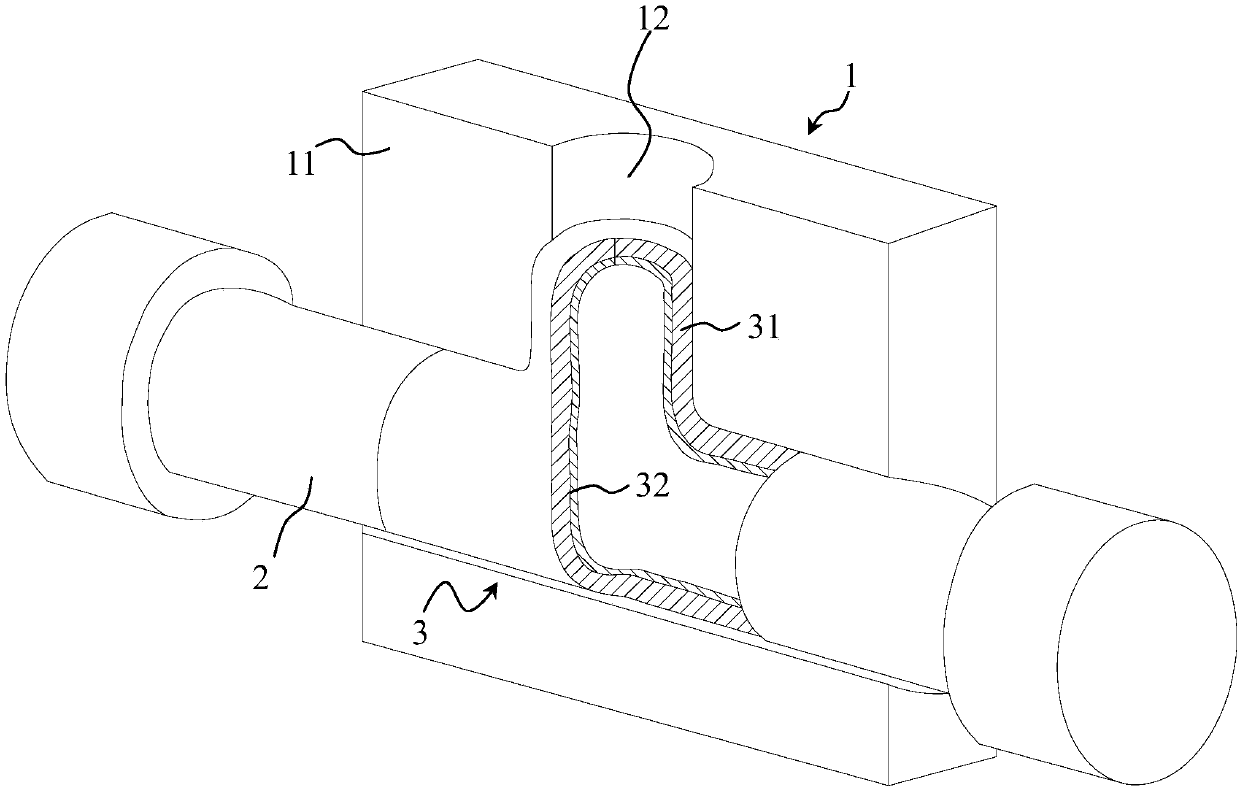

[0028] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and should not be used to limit the scope of protection of this patent.

[0029] A method for preparing a nickel-based bimetallic composite pipe fitting, taking pipeline steel L360 as the metal outer pipe 31 and N08825 as the nickel-based alloy lining pipe as an example, the steps of the method are as follows:

[0030] like figure 1 , The metal outer tube 31 is made of pipeline steel L360, the yield strength of the metal outer tube 31 is less than two-thirds of the maximum tensile strength of the metal outer tube 31, and it is directly formed by cold pushing. In this embodiment, the mold 1 is set in a cold extrusion molding machine, and the mold 1 includes two half-moulds 11 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com