A heat treatment process for reducing the deformation of the gear shaft keyway

A gear shaft and keyway technology, which is applied to the shoulder reducer of an industrial robot and the heat treatment process field of reducing the deformation of the gear shaft keyway, can solve the problems of low yield and large deformation of the gear shaft keyway, etc., so as to improve the wear resistance, Relief of machining stress, uniform heating and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

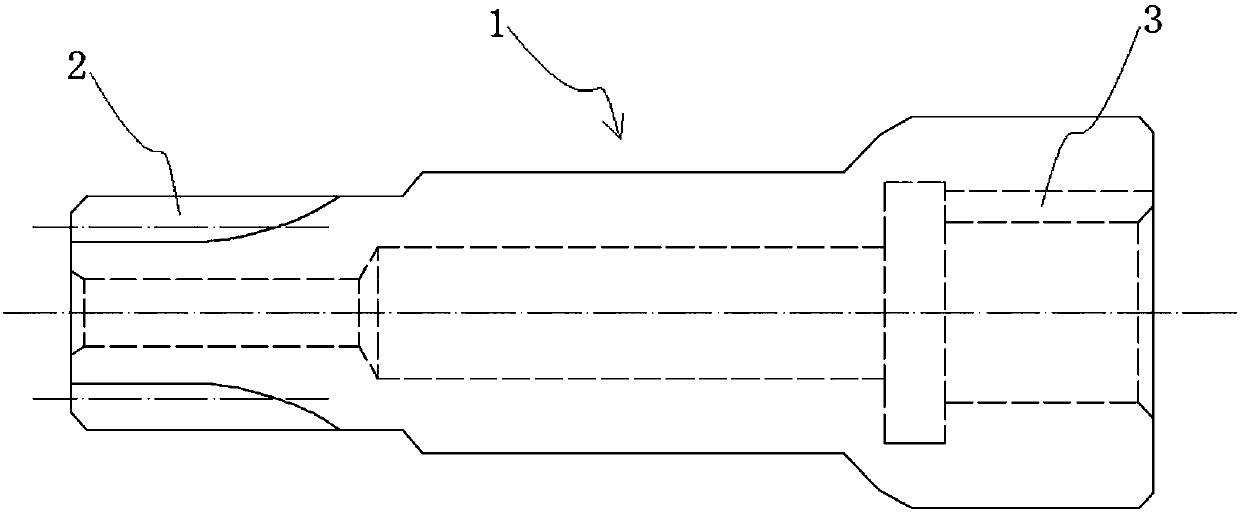

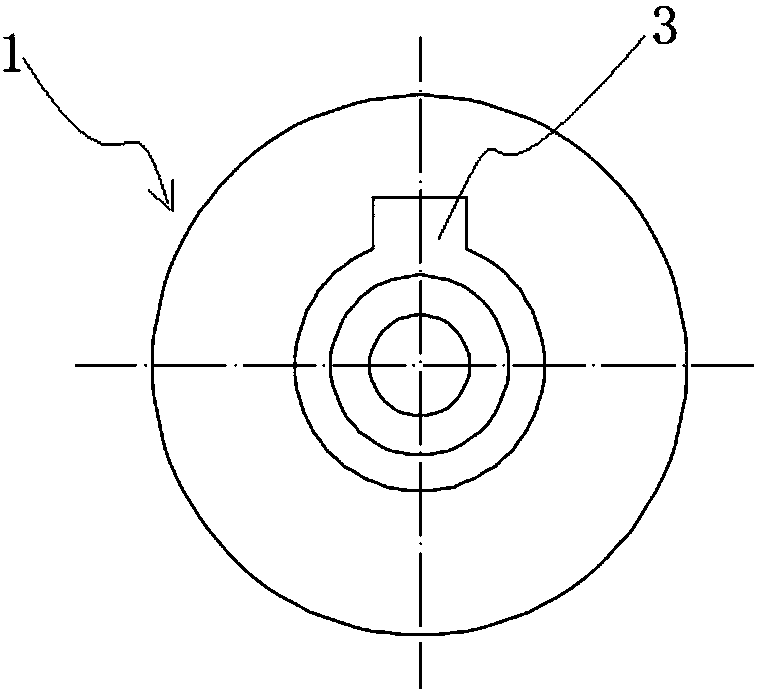

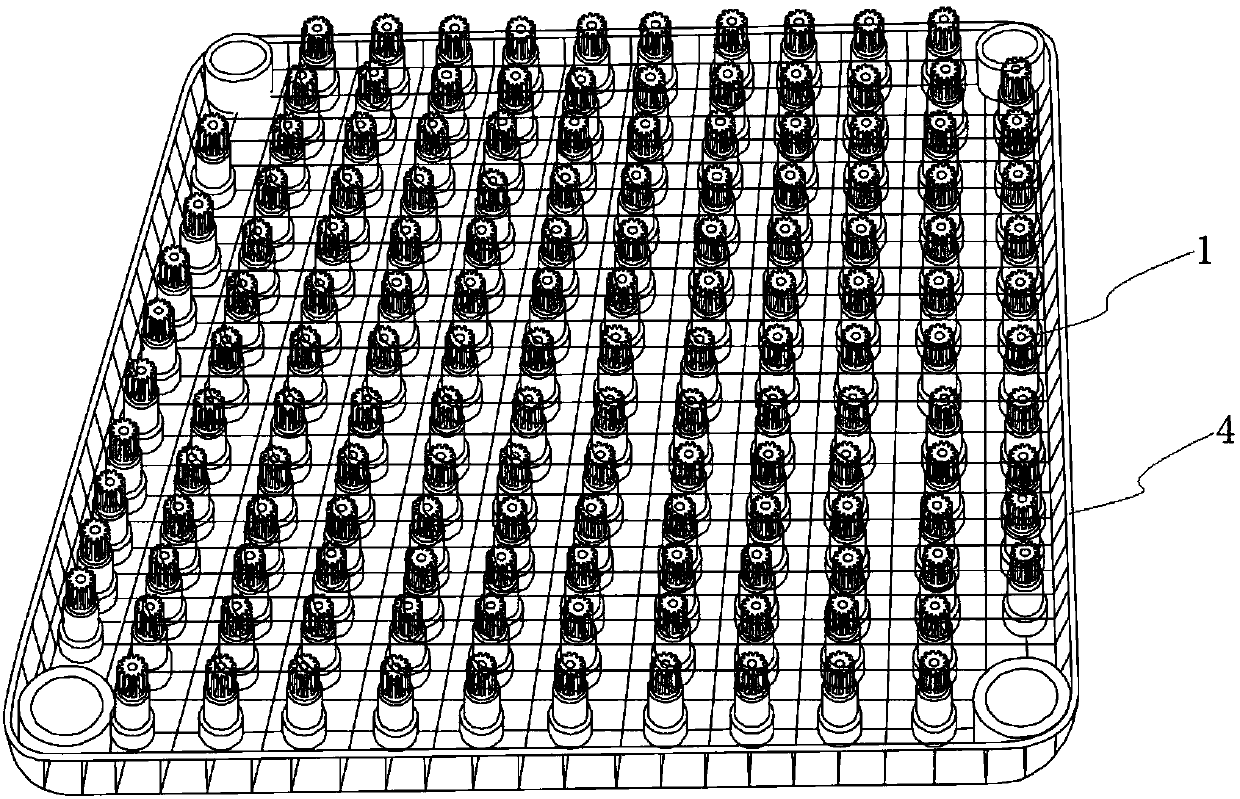

[0045]Take the heat treatment process of an input gear shaft for an industrial robot shoulder reducer with a modulus of 2.215 and a number of teeth of 13 as an example. The technical requirements for heat treatment are: surface hardness is 80.1-82.1HRA, and the effective hardened layer depth is 0.25-0.63mm. The parallelism of the keyway is ≤0.035mm (the parallelism of the keyway before heat treatment is ≤0.02mm), and the tolerance of the keyway is ±0.015mm (the tolerance of the keyway before heat treatment is ±0.008mm). In order to meet the above heat treatment requirements, a heat treatment process for reducing the deformation of the keyway of the gear shaft in this embodiment includes the following steps:

[0046] (1) Parts preparation: Carry out high-temperature normalizing treatment on the alloy steel billet with the brand name SCM420, so that the surface hardness of the billet can reach 150-170HBW, and uniform ferrite and pearlite structures can be obtained. The preparator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com