Method for surface modification and high strength connection of magnesium alloy and aluminum alloy

A technology for aluminum alloy surface and surface modification, applied in welding equipment, metal processing equipment, metal material coating technology, etc., can solve problems such as low strength of welded joints, difficulties in reliable connection, and difficult control of welding processes, etc., to eliminate The effect of pristine interface, small deformation and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

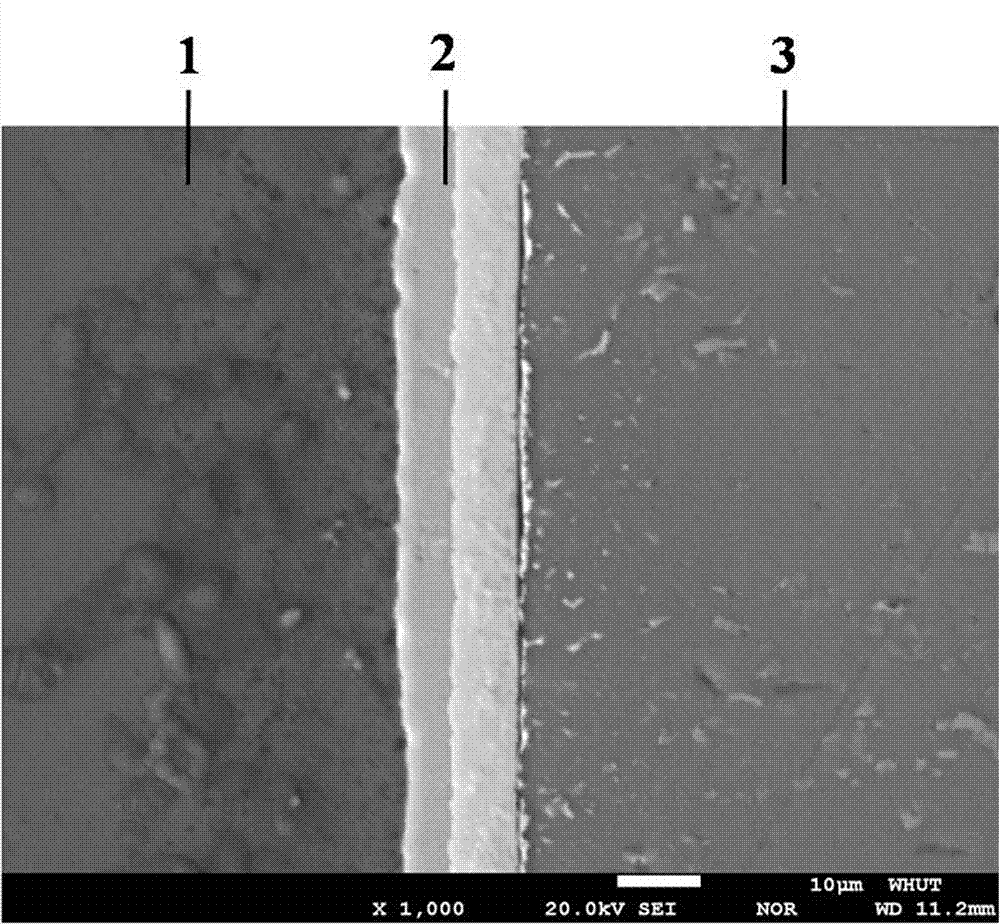

[0036] Surface modification treatment and vacuum diffusion solid phase connection are carried out on magnesium alloy and aluminum alloy. Among them, the magnesium alloy to be welded is pure magnesium with a diameter of Φ25×5mm Mg1, and the aluminum alloy to be welded is pure aluminum with a diameter of Φ25×5mm1060A. The thickness of the magnetron sputtering Ag interlayer is 1.5 μm, and the process conditions of diffusion bonding are: welding temperature 380°C, holding time 90min, and welding pressure 10MPa.

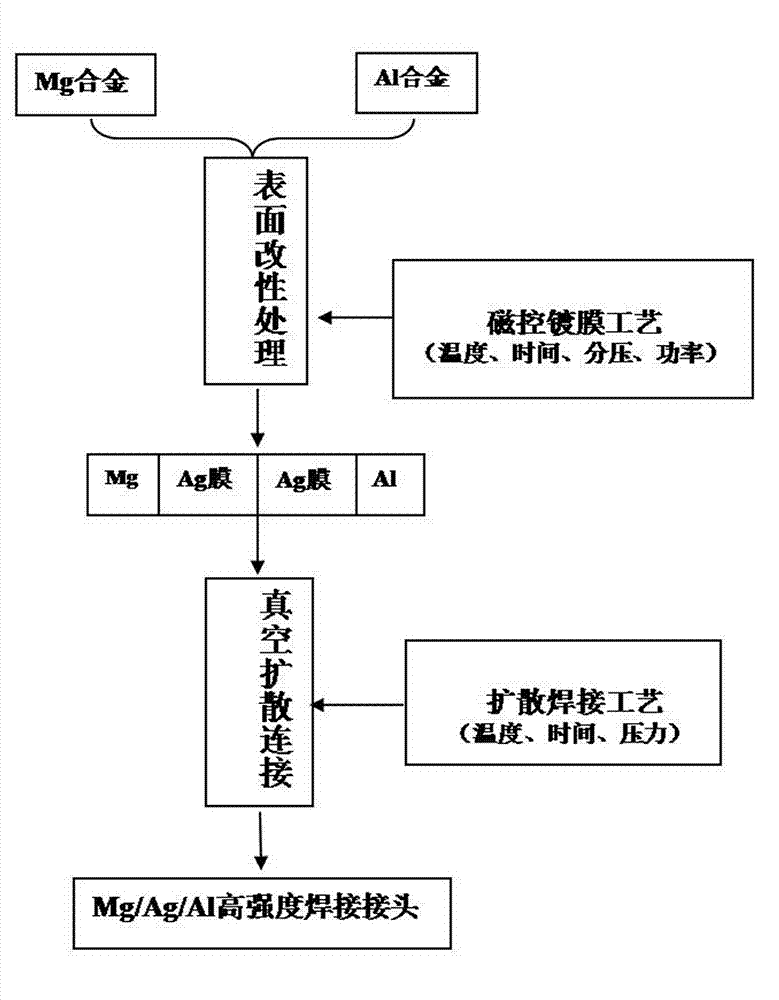

[0037] The specific steps are as follows (see figure 1 ):

[0038] 1. Magnesium alloy and aluminum alloy machining and surface coating modification treatment:

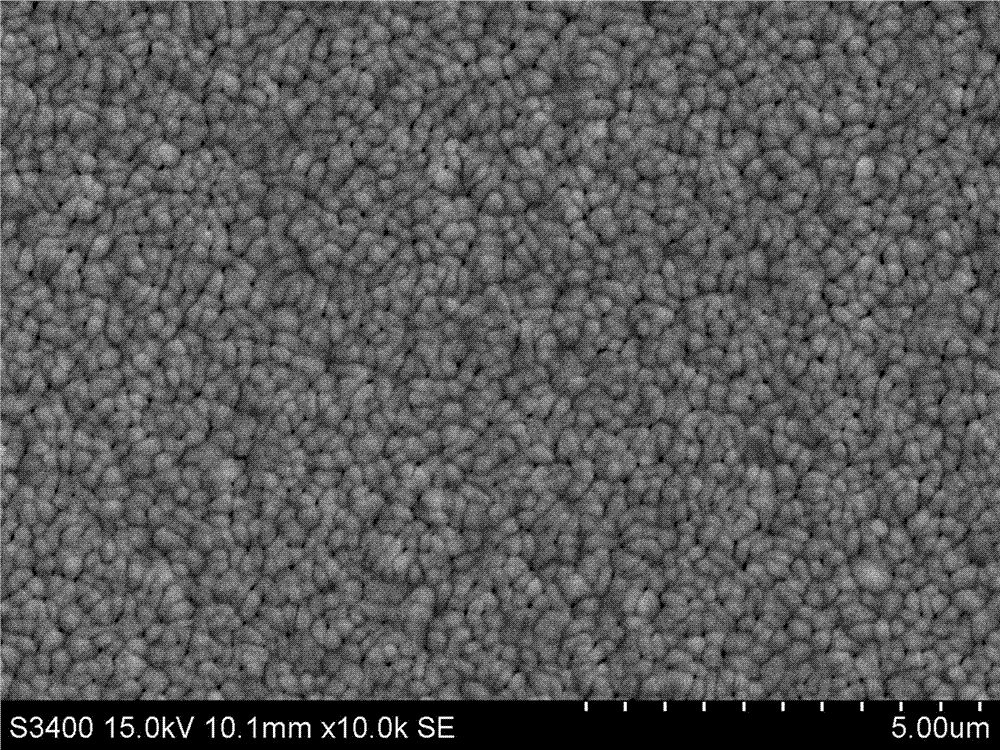

[0039] Magnesium alloys and aluminum alloys are processed into round sheets with ultra-precision surface grinders, and 1000 # , 1200 #SiC sandpaper and metallographic sandpaper No. 05, 06, and 07 were used to polish the surface of the circular slice to be welded, and polished with a high-precision polishing mac...

Embodiment 2

[0046] Surface modification treatment and vacuum diffusion solid phase connection are carried out on magnesium alloy and aluminum alloy. Among them, the magnesium alloy to be welded is pure magnesium with a diameter of Φ25×5mm Mg1, and the aluminum alloy to be welded is pure aluminum with a diameter of Φ25×5mm1060A. The magnetron sputtering Ag intermediate layer 7 has a thickness of 2.5 μm, and the diffusion bonding process conditions are: welding temperature 390° C., holding time 30 minutes, and welding pressure 5 MPa.

[0047] The specific steps are as follows (see figure 1 ):

[0048] 1. Magnesium alloy and aluminum alloy machining and surface coating modification treatment:

[0049] Magnesium alloys and aluminum alloys are processed into round sheets with ultra-precision surface grinders, and 1000 # , 1200 # SiC sandpaper and metallographic sandpaper No. 05, 06, and 07 were used to polish the surface of the circular slice to be welded, and polished with a high-precision...

Embodiment 3

[0056] Surface modification treatment and vacuum diffusion solid phase connection are carried out on magnesium alloy and aluminum alloy. Among them, the magnesium alloy to be welded is pure magnesium with a diameter of Φ25×5mm Mg1, and the aluminum alloy to be welded is pure aluminum with a diameter of Φ25×5mm1060A. The thickness of the Ag interlayer by magnetron sputtering is 2.5 μm, and the process conditions of diffusion bonding are: welding temperature 420°C, holding time 30min, and welding pressure 5MPa.

[0057] The specific steps are as follows (see figure 1 ):

[0058] 1. Magnesium alloy and aluminum alloy machining and surface coating modification treatment:

[0059] Magnesium alloys and aluminum alloys are processed into round sheets with ultra-precision surface grinders, and 1000 # , 1200 # SiC sandpaper and metallographic sandpaper No. 05, 06, and 07 were used to polish the surface of the circular slice to be welded, and polished with a high-precision polishing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com