Rotational molding manufacturing method for double-layer all-plastic ship

A manufacturing method and ship technology, applied in the direction of coating, etc., can solve the problems of waste of materials and inability to achieve, and achieve the effect that the hull is strong and not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

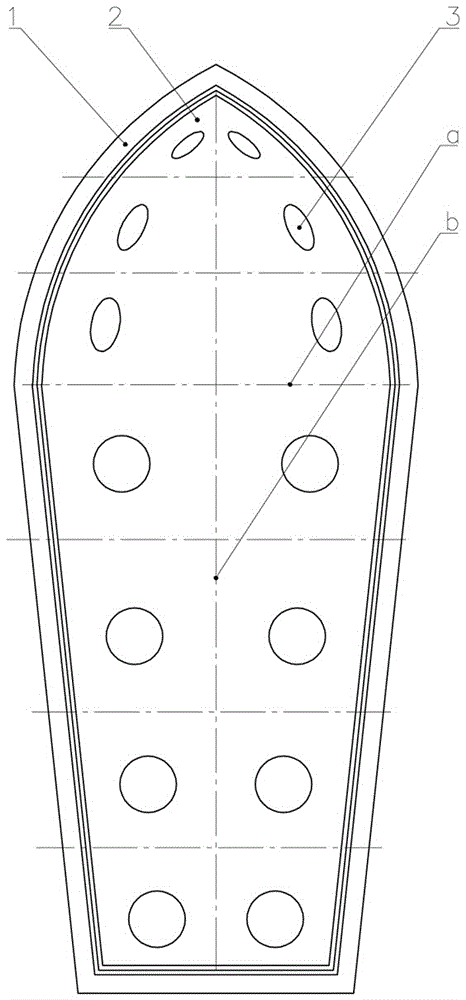

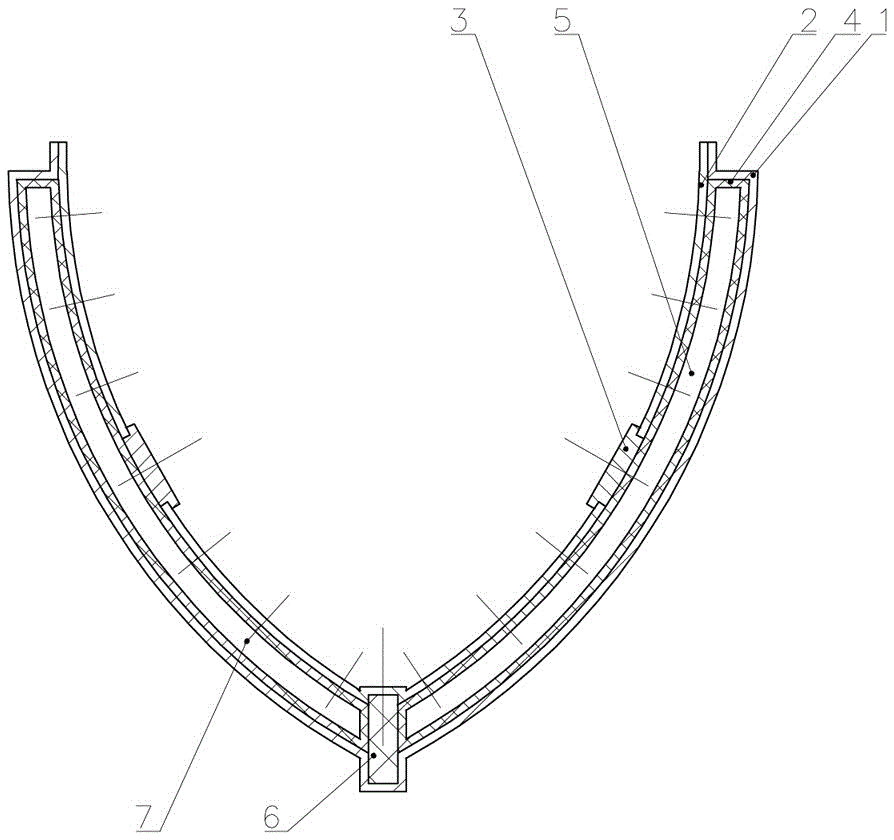

[0016] 1. A method for manufacturing double-layer all-plastic ship rotational molding, the process is:

[0017] 1) Fix the supporting frame inside the inner mold body with the supporting frame fixing device, the supporting frame has upper and lower parallel surfaces, and its upper surface is attached to the inner wall of the inner mold;

[0018] 2) The inner and outer mold bodies are combined, and the lower surface of the supporting frame is attached to the inner wall of the outer mold;

[0019] 3) Add plastic and other raw materials to each cavity area between the inner and outer mold bodies through the feeding port, and the cavity area is divided by the supporting frame;

[0020] 4) Heating and rolling the mold to melt and mix the plastic and other raw materials on the inner wall of the mold;

[0021] 5) Cooling and demoulding.

[0022] The supporting frame used is molded from the same material as the hull shell. The supporting frame is divided into keels, ribs and reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com