Plastic catamaran

A technology of plastic catamaran and plastic sheet, which is applied in the direction of hull, hull design, ship construction, etc., can solve the problems of high production cost, broken hull into water, heavy ship weight, etc., and achieves low production cost and simple manufacturing process. , the effect of low resistance of the boat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

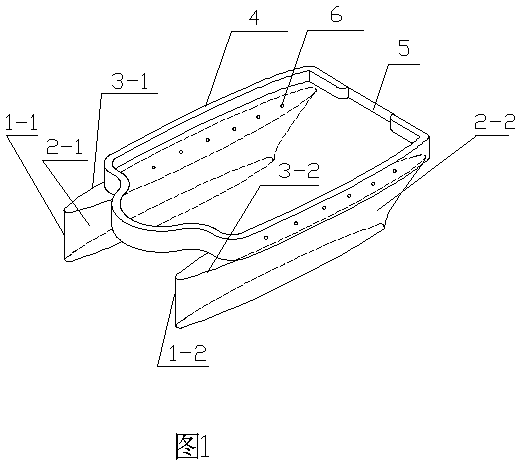

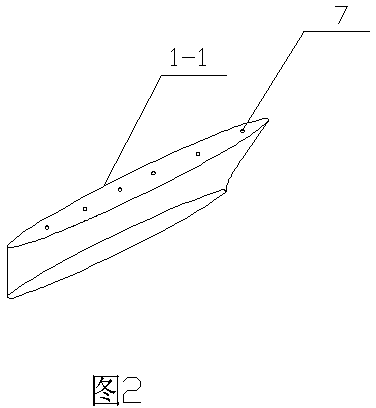

[0029] (1) Production of the left hull: According to the shape of the left hull of the catamaran, cut the weather-resistant polypropylene sheet into the required shape, and then make the left hull by welding (1-1 ),Such as figure 2 shown.

[0030] (2) Manufacturing of the right side hull: The manufacturing method of the right hull is the same as that of the left hull (1-1).

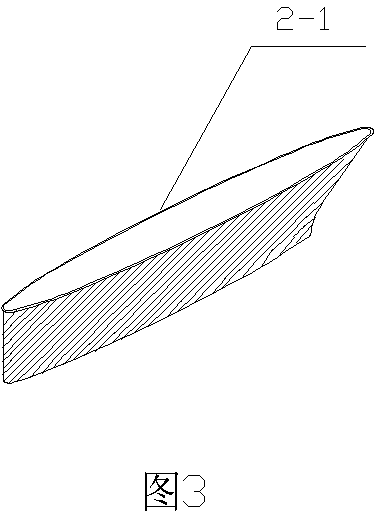

[0031] (3) Production of the foam block on the left side of the hull: Cut the high foaming polypropylene foam into image 3 Shape shown, this creates the hull left foam block (2-1).

[0032] (4) Manufacturing of the foam block on the right side of the hull: the manufacturing method of the foam block (2-2) on the right side of the hull is the same as that of the foam block (2-1) on the left side of the hull, for example image 3 shown.

[0033] (5) Fabrication of the left hull cover plate: Cut the weather-resistant polypropylene sheet into the required shape according to the shape of the left hull cove...

Embodiment 2

[0038] (1) Production of the left hull: According to the shape of the left hull of the catamaran, cut the polycarbonate sheet into the required shape, and then make the left hull by welding (1-1 ),Such as figure 2 shown.

[0039] (2) Manufacturing of the right side hull: The manufacturing method of the right hull is the same as that of the left hull (1-1).

[0040] (3) Production of the foam block on the left side of the hull: Cut polyurethane rigid foam into image 3 Shape shown, this creates the hull left foam block (2-1).

[0041] (4) Manufacturing of the foam block on the right side of the hull: the manufacturing method of the foam block (2-2) on the right side of the hull is the same as that of the foam block (2-1) on the left side of the hull, for example image 3 shown.

[0042] (5) Fabrication of the left hull cover: Cut the polycarbonate sheet into the required shape according to the shape of the left hull cover, and drill 12 uniform holes on the left hull cover w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com