Building inner and outer wall decorating plate and manufacturing method thereof

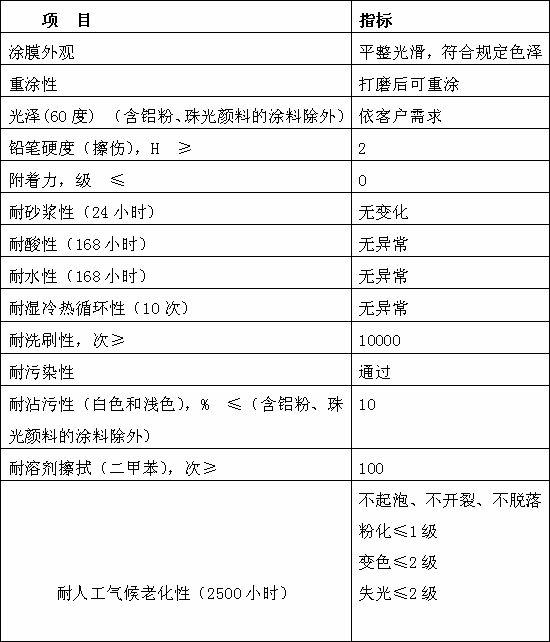

A manufacturing method and technology for decorative boards, which are applied in construction, building construction, and devices for coating liquid on the surface, etc., which can solve the problems of poor boiling water resistance of boards, cracking boards, poor adhesion between paint layers and boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

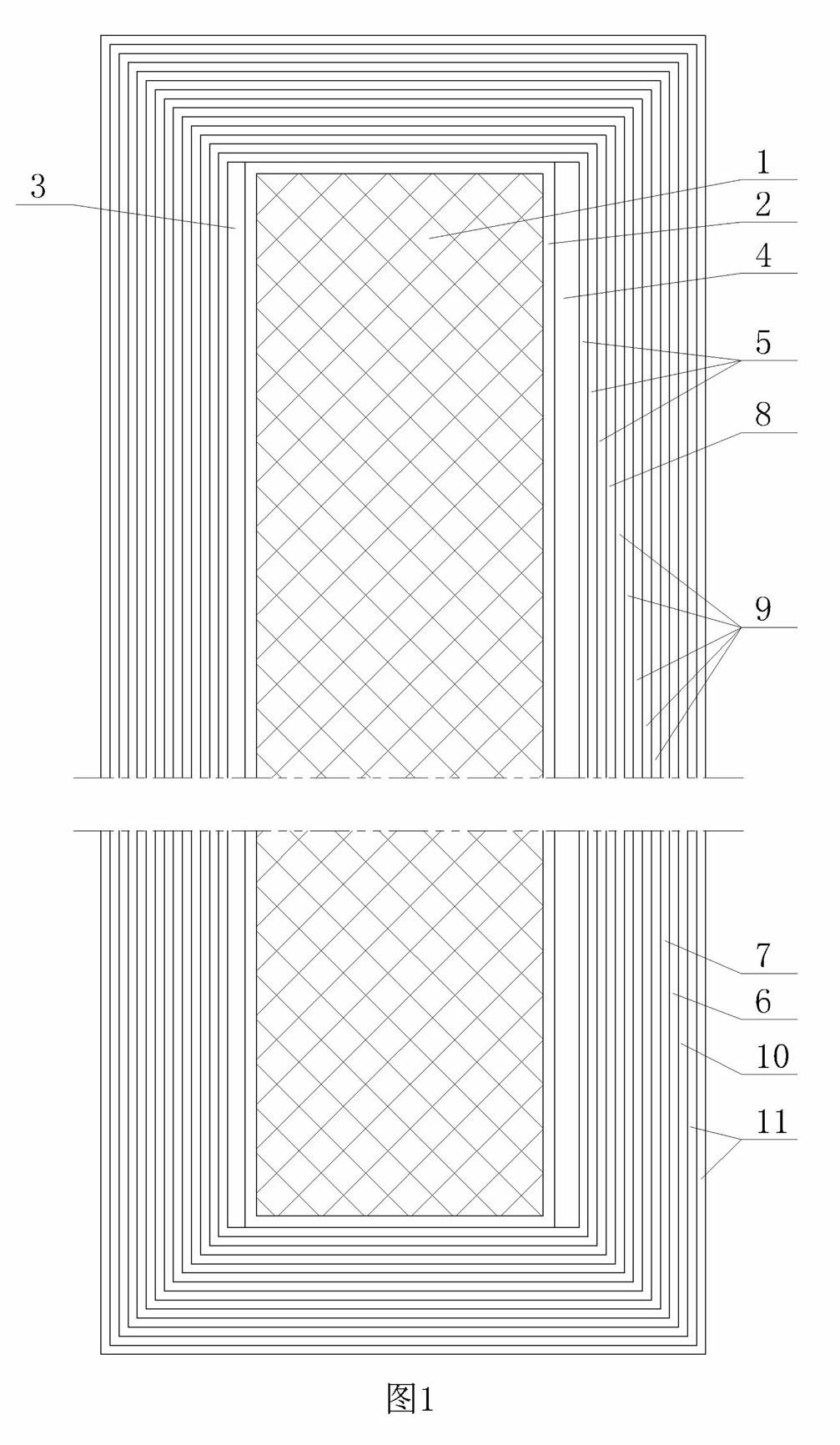

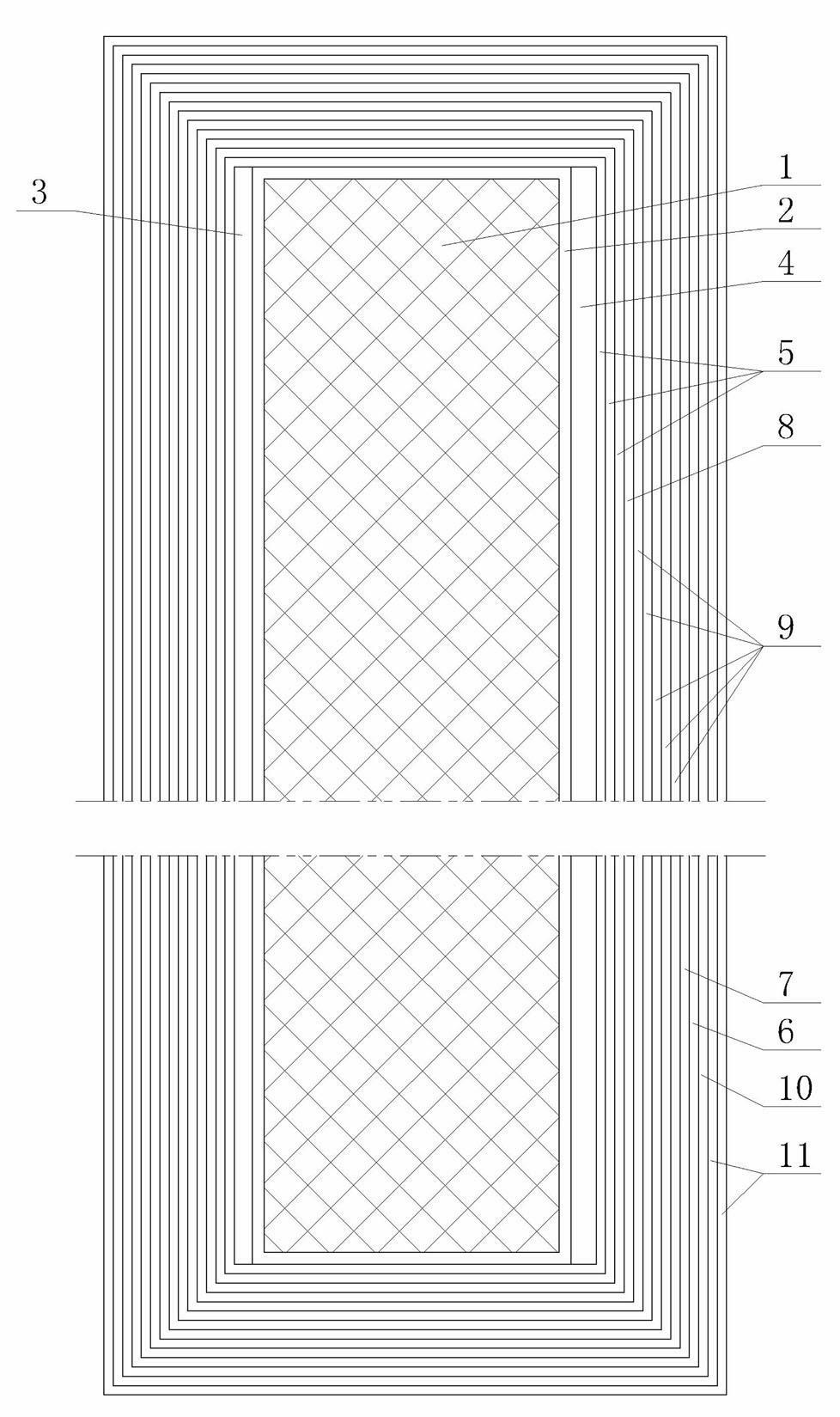

[0029] The building interior and exterior wall decoration board of the present invention comprises a plate 1, the front of the plate 1 is provided with a UV putty layer 4, the back side of the plate 1 is provided with a first UV sealing paint layer 3, the plate 1, the first UV sealing paint layer 3 The outer periphery of the UV putty layer 4 is provided with three layers of second UV sealing paint layers 5, and the outside of the second UV sealing paint layer 5 is provided with a first UV adhesive layer 8 and five layers of UV topcoat layers 9. The outside of the UV topcoat layer 9 is provided with a second UV glue layer 7 , the outside of the second UV glue layer 7 is provided with a bionic film 6 , and the outside of the biomimetic film 6 is provided with two layers of second UV paint layers 11 . The second UV sealing paint layer 5 of the third layer is a white primer, and its thickness is 70-110 microns.

[0030] A method for manufacturing interior and exterior wall decorat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com