Method for building built-up steel structure bearing walling

An assembled, steel structure technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as restricting the development of assembled steel structure buildings, and achieve the effects of low cost, short construction period, and rapid on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

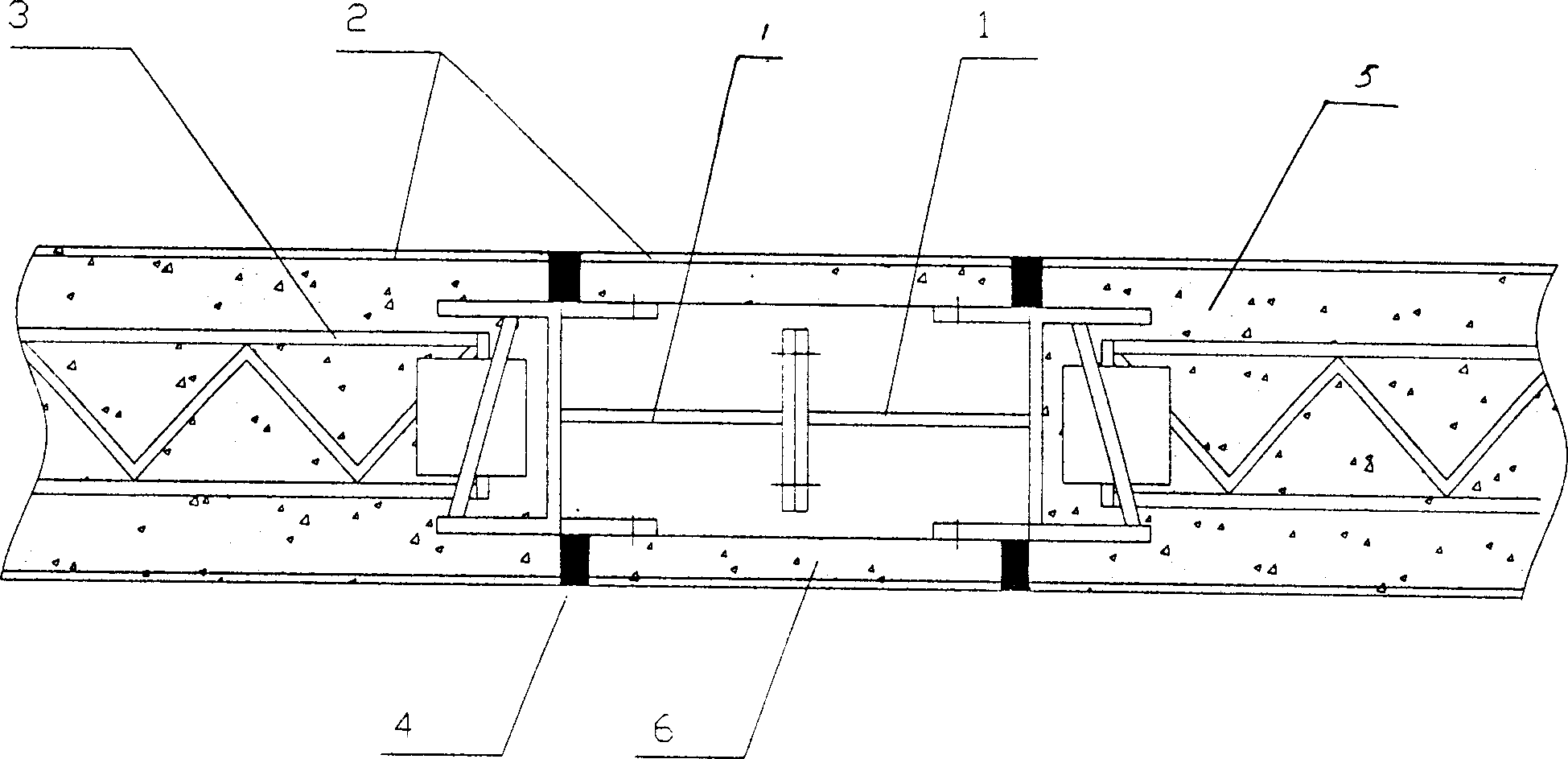

[0017] Such as figure 1 As shown, the "one" font assembled steel structure load-bearing wall of the present invention.

[0018] A light-weight building board, which uses profiled steel with webs as the frame 1, a cement layer reinforced with crack-resistant materials as the surface layer 2, and steel trusses or profiled steels as reinforcing ribs 3, which are combined with foamed cement 5. become. Connect two such lightweight building boards, and fix the two frames 1 to form a "one"-shaped structure; and use two strip-shaped building boards 6 to seal the "one"-shaped structure; then use a sealing material 4. Seal it to form a "one"-shaped assembled steel structure load-bearing wall.

Embodiment 2

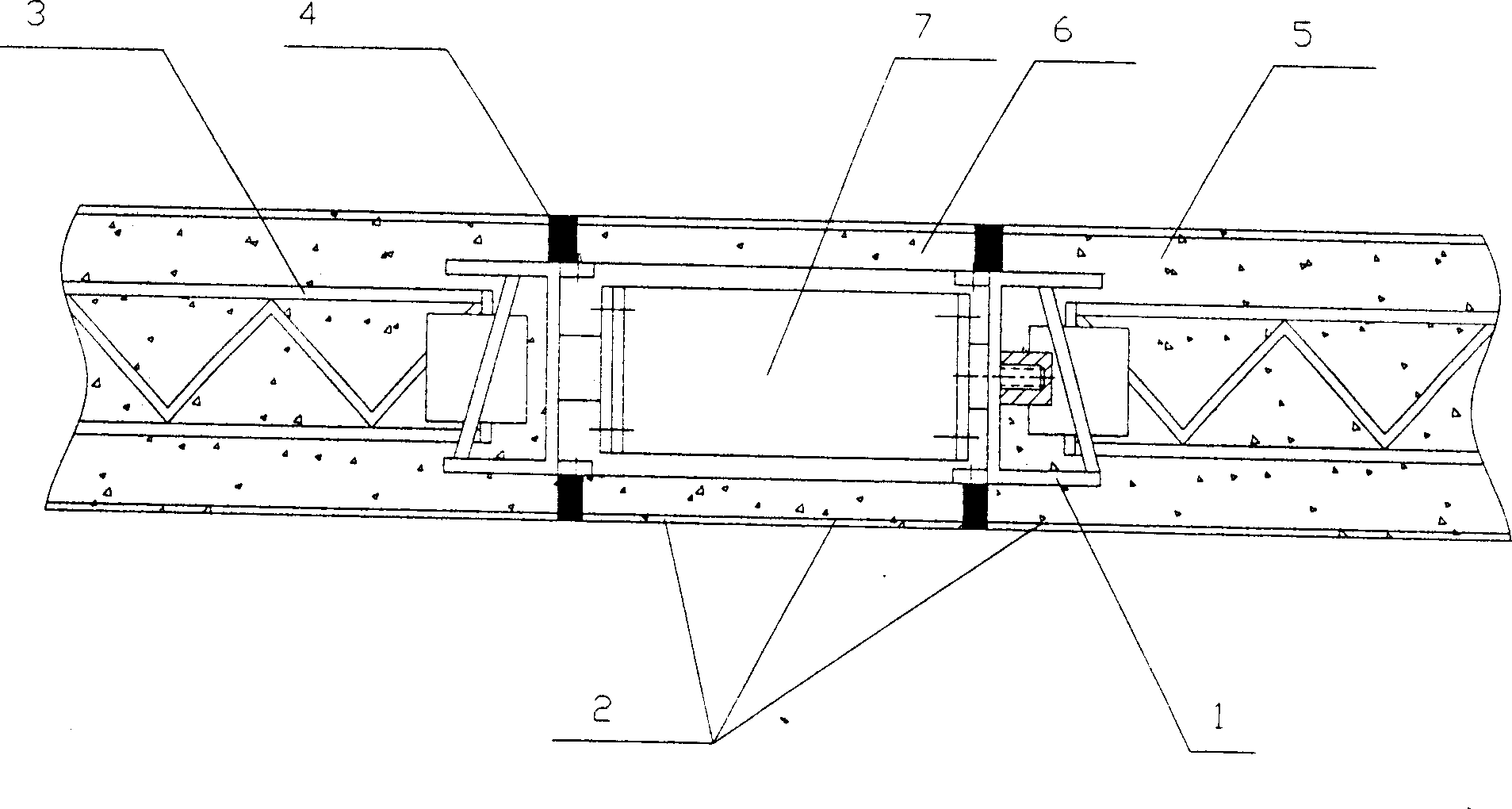

[0020] Such as figure 2 As shown, another "one"-shaped assembled steel structure load-bearing wall of the present invention can save steel and increase the rigidity and strength of the building frame.

[0021] A light building board, which is composed of shaped steel as a frame 1, a cement layer reinforced with anti-cracking materials as a surface layer 2, steel trusses or shaped steel as reinforcing ribs 3, and combined with foamed cement 5. Two pieces of such lightweight building boards are fixedly connected to each other through rods 7 to form a "one"-shaped structure; and two strip-shaped building boards 6 are used to seal the "one"-shaped structure; and then sealed with a sealing material 4 , forming a "one"-shaped assembled steel structure load-bearing wall.

Embodiment 3

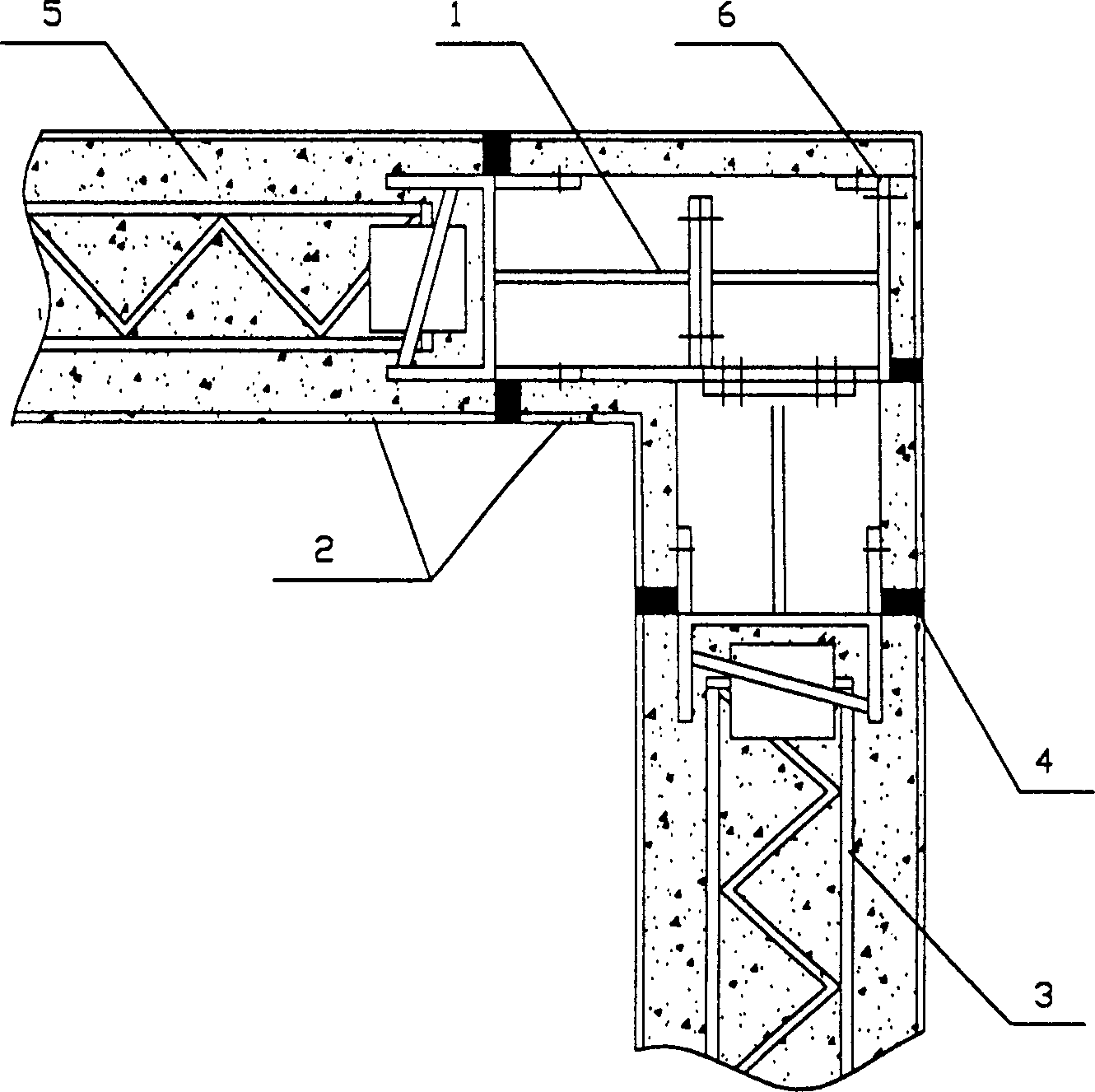

[0023] Such as image 3 As shown, the angle-shaped assembled steel structure load-bearing wall of the present invention.

[0024] A light-weight building board, which uses profiled steel with webs as the frame 1, a cement layer reinforced with crack-resistant materials as the surface layer 2, and steel trusses or profiled steels as reinforcing ribs 3, which are combined with foamed cement 5. become. Place two such lightweight building boards at right angles, and fix the two frames 1 to form a corner structure; and use two corner building boards 6' to seal the corner structure; then seal the corner structure with a sealing material 4 to form a Angle-shaped assembled steel structure load-bearing wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com