Bacillus subtilis gene engineering strain, construction method thereof and application in lactulose production

A technology of Bacillus subtilis and genetically engineered bacteria, applied in the field of bioengineering, can solve problems such as potential safety hazards, and achieve the effects of improving productivity, avoiding loss of enzyme activity, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

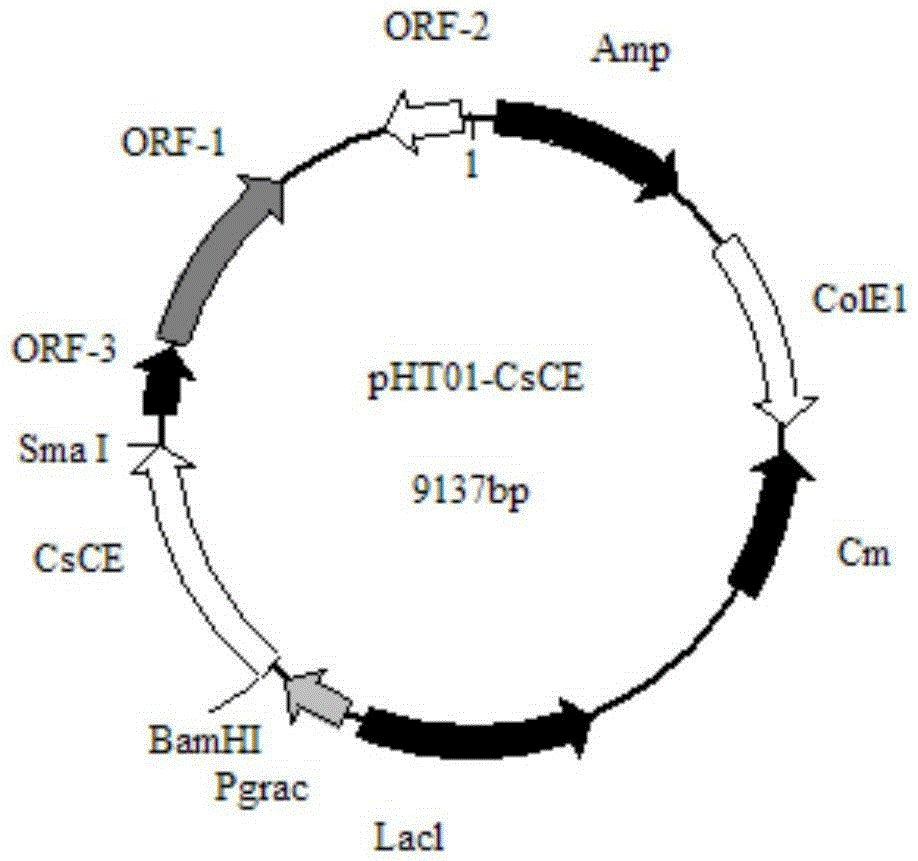

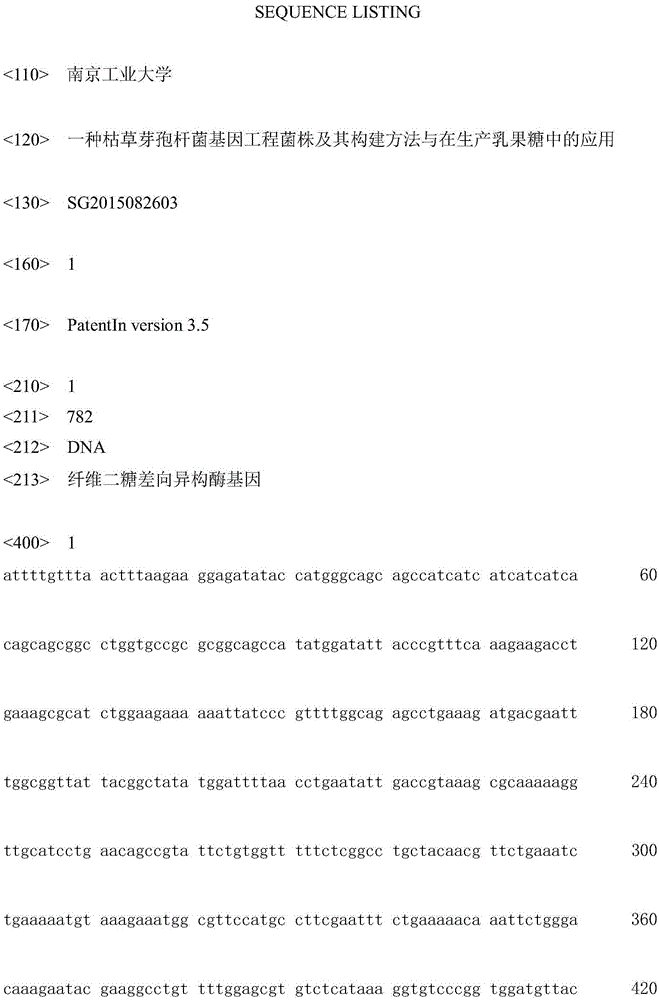

[0038] Example 1: Synthesis of the cellobiose epimerase gene.

[0039] According to the reported gene sequence of cellobiose epimerase, the gene sequence shown in SEQ ID NO.1 was synthesized by the method of total gene synthesis.

Embodiment 2

[0040] Example 2: Construction of recombinant Bacillus subtilis.

[0041]Using the DNA obtained in Example 1 as a template, the cellobiose epimerase gene fragment was amplified. The PCR amplification system is: 2 μL of synthesized DNA, 1 μL of each primer Primer1 and Primer2, 2 μL of dNTP, 2.5 μL of 10×Ex-Tag buffer, 0.5 μL of Ex-Tag polymerase, ddH 2 O14 μL. The PCR reaction program was: pre-denaturation at 94°C for 2 min, denaturation at 94°C for 2 min; then annealing at 60°C for 30 s, extension at 72°C for 1 min, and 35 cycles; extension at 72°C for 1 min.

[0042] The amplified bands were gel-cut and recovered with a column-type gel-slicing recovery kit, and the PCR product was double-digested with BamHI and SmaI. The digestion system is: 50 μL of PCR product or plasmid, 1 μL of XhoI, 1 μL of NdeI, 10 μL of 10× buffer, ddH 2 O38μL, total volume 100μL.

[0043] The digested PCR product was ligated with the pHT-01 plasmid (or pHT-43 plasmid) treated with the same restric...

Embodiment 3

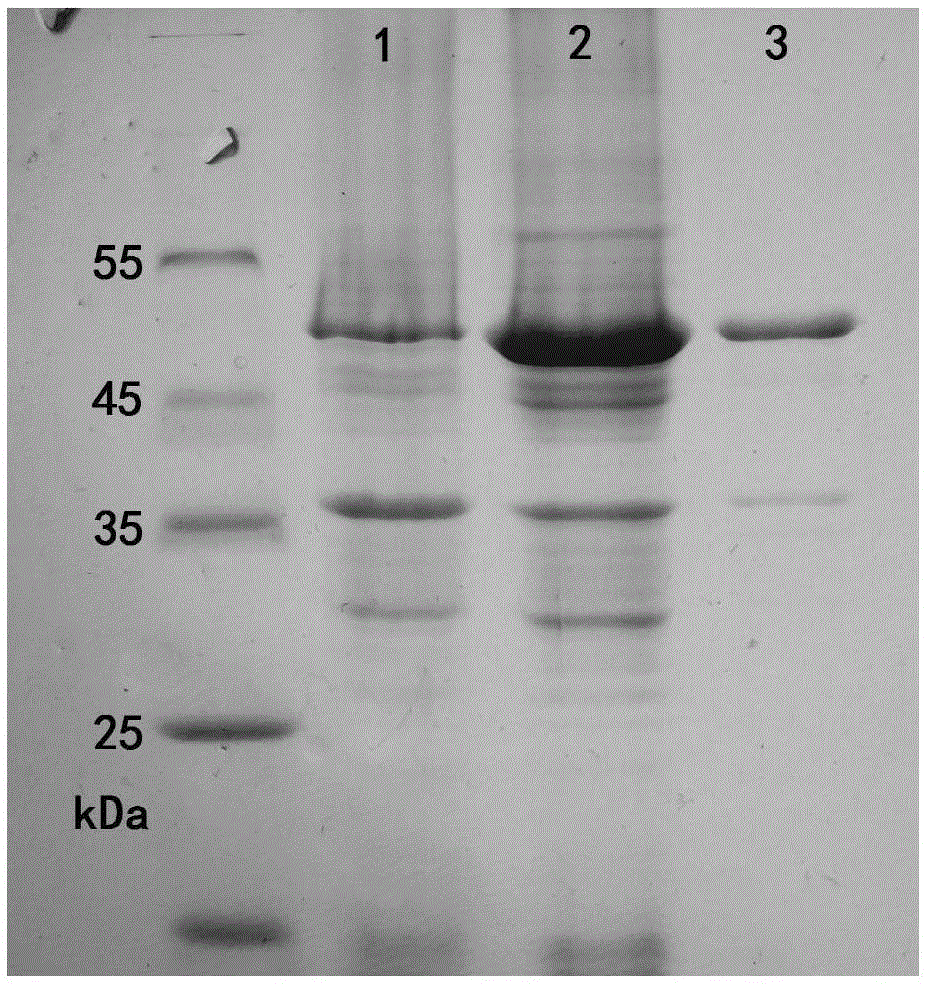

[0045] Example 3: Inducible expression of cellobiose epimerase.

[0046] The constructed recombinant Bacillus subtilis str.168 (pHT-01-CsCE) was inoculated in 5 ml of LB liquid medium supplemented with ampicillin resistance, and cultivated overnight at 37°C; LB medium, fermented for 2 to 4 hours to OD 600 When reaching 0.6, add 0.6mmol / L isopropyl-β-D-thiogalactopyranoside (IPTG) or 10g / L lactose to continue to induce expression for 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com