Lactose enzyme and common immobilization method of glucose isomerase

A technology of glucose isomerase and lactase, which is applied in the field of embedding-crosslinking and co-immobilization of lactase and glucose isomerase, can solve the problems of deep color, high cost and many by-products, and achieve Improve reaction efficiency and product quality, enhance market competitiveness, and save economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: prepare 20 g of pH 8.6 27% (w / w) gelatin solution, dissolve the gelatin completely in a water bath at 30° C., dissolve lactase and glucose isomerase in 2 mL of deionized water according to the activity ratio of 1:1, and dissolve Add the enzyme solution to the gelatin so that the amount of the two enzymes added is 3 U / g (gelatin solution), stir and mix well, then add 2 mL of glutaraldehyde with a volume fraction of 0.15%, pour it into a petri dish immediately after stirring, and It was cured overnight at 4°C, and the next day it was immersed in 0.15% glutaraldehyde for crosslinking at 4°C for 10 minutes, then washed with deionized water several times, the surface water was blotted with filter paper, and finally cut into small squares of 2mm square. The recovery rate of lactase in the co-immobilized enzymes was measured to be 30.85%, and the recovery rate of glucose isomerase was 83.48%.

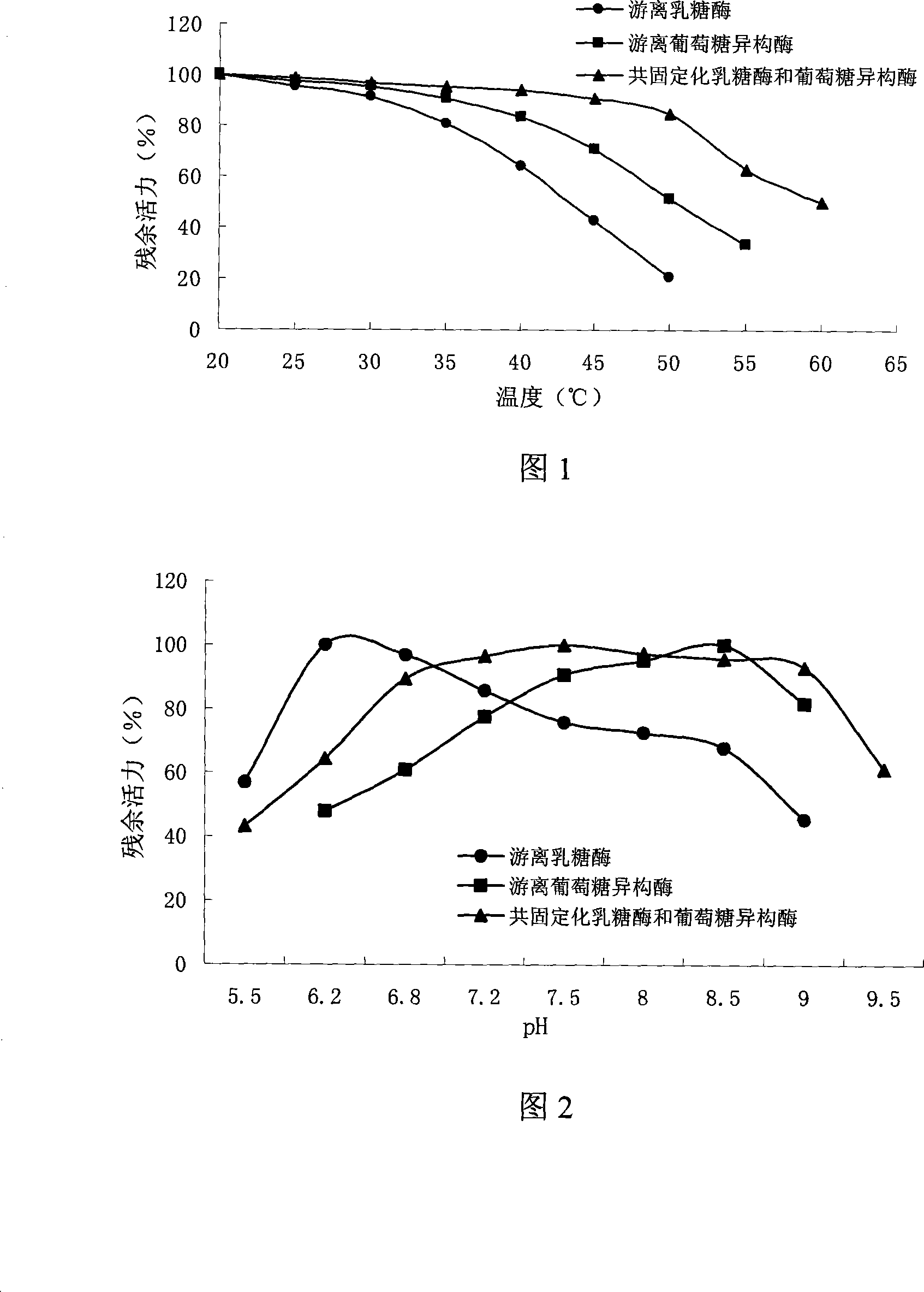

[0030] Figure 1 shows the thermal stability changes of free lactase, fre...

Embodiment 2

[0033] Example 2: Prepare 20 g of mixed glue solution containing gelatin and sodium alginate with a mass concentration of 20% and 4% respectively, pH 7, dissolve completely in a water bath at 30°C, and isomerize lactase and glucose according to the activity ratio of 1:2 Dissolve the enzyme in 2mL of deionized water, add the enzyme solution to the mixed glue, make the addition amount of lactase and glucose isomerase respectively 9U / g and 18U / g (mixed glue), stir and mix well, then add 2mL of glutaraldehyde with a volume fraction of 0.25% was injected into the Petri dish, and after condensation, it was condensed with 4% CaCl 2 Soak overnight. The next day, it was washed with deionized water, and after clearing, it was cross-linked with 0.25% glutaraldehyde at 15°C for 30 minutes, then washed with deionized water several times, the surface water was blotted with filter paper, and cut into small squares of 2mm square.

Embodiment 3

[0034] Example 3: prepare 20 mL of carrageenan solution with pH 7.5 20%, completely dissolve the carrageenan in a water bath at 30°C, dissolve lactase and glucose isomerase in 2 mL of deionized water according to the activity ratio of 1:5, and dissolve the enzyme solution Add it to the carrageenan solution so that the amount of lactase and glucose isomerase added is 6U / g and 30U / g (carrageenan solution) respectively, stir and mix well, then add 2mL of glutaraldehyde with a volume fraction of 1%, Immediately after stirring, it was poured into a Petri dish, and after solidification, it was immersed in 0.2mol / L KCl to harden overnight at 4°C. The next day, cross-link with 1% glutaraldehyde at 30°C for 40 min, then wash with deionized water several times, blot the surface water with filter paper, and cut into small squares of 2 mm square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com