Hand cleaner composition

A technology of composition and hand sanitizer, which is applied in the direction of skin care preparations, cosmetics, cosmetic preparations, etc., can solve the problems of incomplete shedding of cured film, uneven rubbing action, residue, etc., and achieve good cleaning effect and skin irritation Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

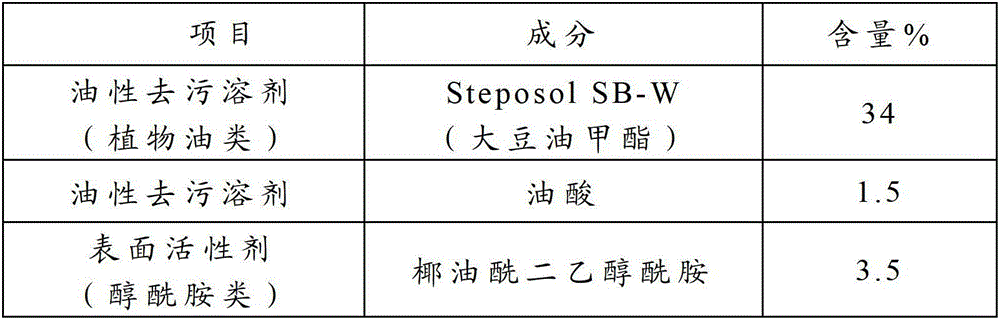

[0044] Configure the hand sanitizer composition according to the formula shown in Table 1.

[0045] Preparation process steps: Mix Steposol SB-W (soybean oil methyl ester), cocoyl diethanolamide, nonylphenol polyoxyethylene ether-10, oleic acid, PEG-75 lanolin under stirring, and heat to 70°C to prepare Get Phase A. Mix triethanolamine and water in another container with stirring, and heat to 70°C to prepare phase B. While stirring at a temperature of 70-75°C, add phase B to phase A, keep the temperature, and mix for 30 minutes. Cool to room temperature under stirring, add inulin, preservatives and flavors below 50°C to prepare a hand sanitizer composition.

[0046] Table I

[0047]

[0048]

Embodiment 2

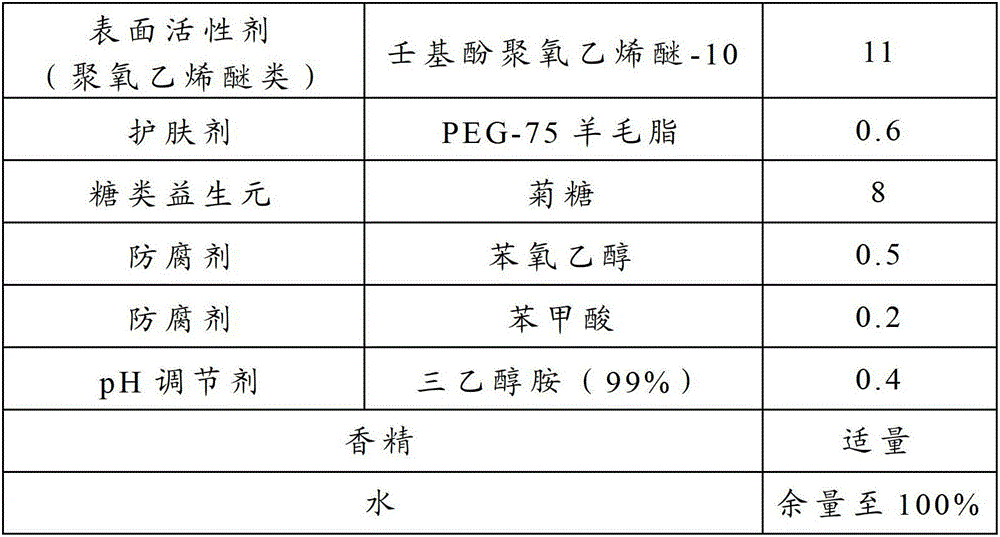

[0050] Configure the hand sanitizer composition by the formula shown in table two.

[0051] Preparation process steps: Add Acusol 820 into water and mix well, then add C12-C15 secondary alcohol polyoxyethylene ether-9 and mix well, stop stirring, add D-ramie and mineral oil and start stirring again, mix until D-ramie Disperse evenly with mineral oil. Slowly add sodium hydroxide, stir until the system is stable, add pumice powder, low-carbon alcohols, sugar prebiotics, preservatives and flavors and stir well to prepare a hand sanitizer composition.

[0052] Table II

[0053]

[0054]

Embodiment 3

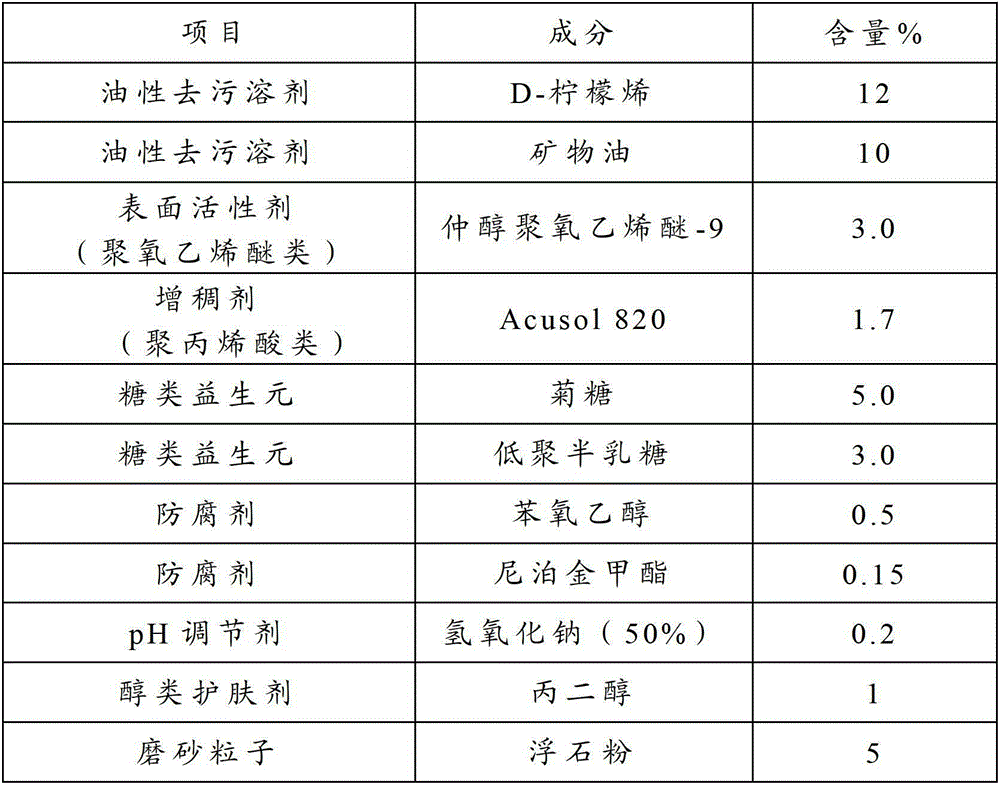

[0056] Configure the hand sanitizer composition according to the formula shown in table three.

[0057] Preparation process steps: Add deionized water into the mixing tank, add cocoyl diethanolamide and cocoalkylamidopropyl betaine under stirring, heat up (<60°C), add sodium lauryl sulfate in turn , fatty alcohol polyoxyethylene ether sodium sulfate, heated to 70-75 ° C to make it completely dissolved, stop heating and cool down to below 45 ° C, then add PEG-75 lanolin, polysaccharide, phenoxyethanol, benzene Formic acid, ethanol, sodium chloride, essence and the like are stirred evenly to prepare a hand sanitizer composition.

[0058] Table three

[0059]

[0060] The hand sanitizer composition that embodiment 1-2 makes is suitable for industrial application, and after the personnel who often touches industrial greasy dirt such as mechanic, car repairman, painter, etc., generally reflects that effect is better than traditional soap, washing powder, cleaning agent, etc. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com