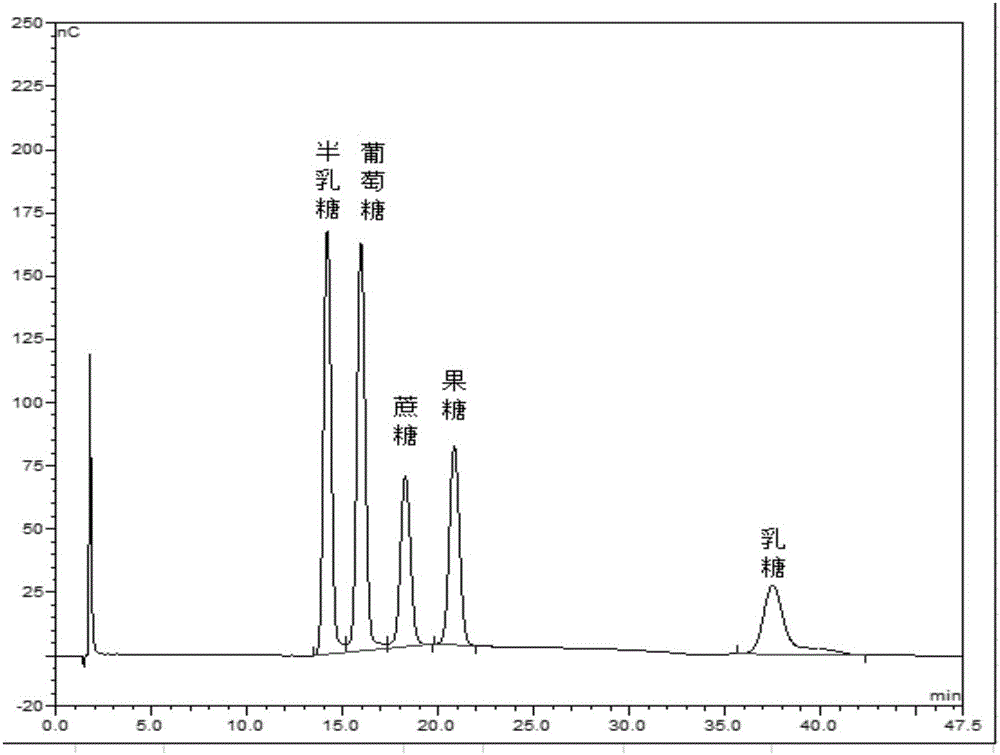

Method for detecting lactulose in milk

A detection method, lactulose technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult separation of lactose and lactulose, difficult quantitative analysis, and strict eluent concentration requirements, achieving separation and good response value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

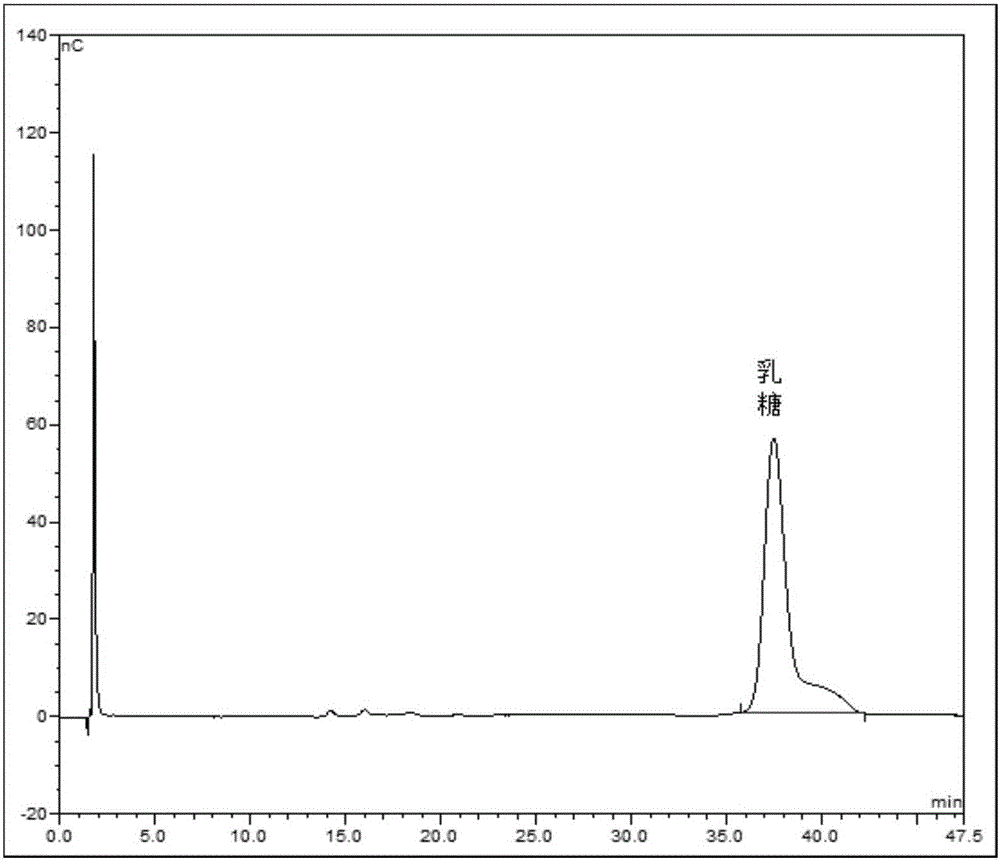

Embodiment 1

[0040] Add lactulose standard solution to the weighed milk blank sample and shake well to prepare the lactulose spiked sample of this embodiment.

[0041] (1) Sample pretreatment

[0042] Pipette 10.00mL of the milk sample to be tested into a 150mL Erlenmeyer flask, add 2mL of potassium ferrocyanide solution with a concentration of 200g / L, 2mL of zinc sulfate solution with a concentration of 200g / L and 6.5mL of buffer [0.34mol / L Disodium hydrogen phosphate (Na 2 HPO 4 )+0.07mol / L sodium dihydrogen phosphate (NaH 2 PO 4 ), pH=7.5], each addition of reagents should be fully shaken, after all additions, let stand for 30 minutes, filter, discard the initial filtrate, and collect the filtrate.

[0043] Take 5 mL of the filtrate into a 10 mL volumetric flask, add 100 μL of β-D-galactosidase suspension, shake well, cover, and incubate at 50°C for 1 hour. Add 2.0mL of buffer solution [0.75mol / L triethanolamine hydrochloride (C 6 h 15 NO 3 ·HCl)+0.01mol / L magnesium sulfate (MgS...

Embodiment 2

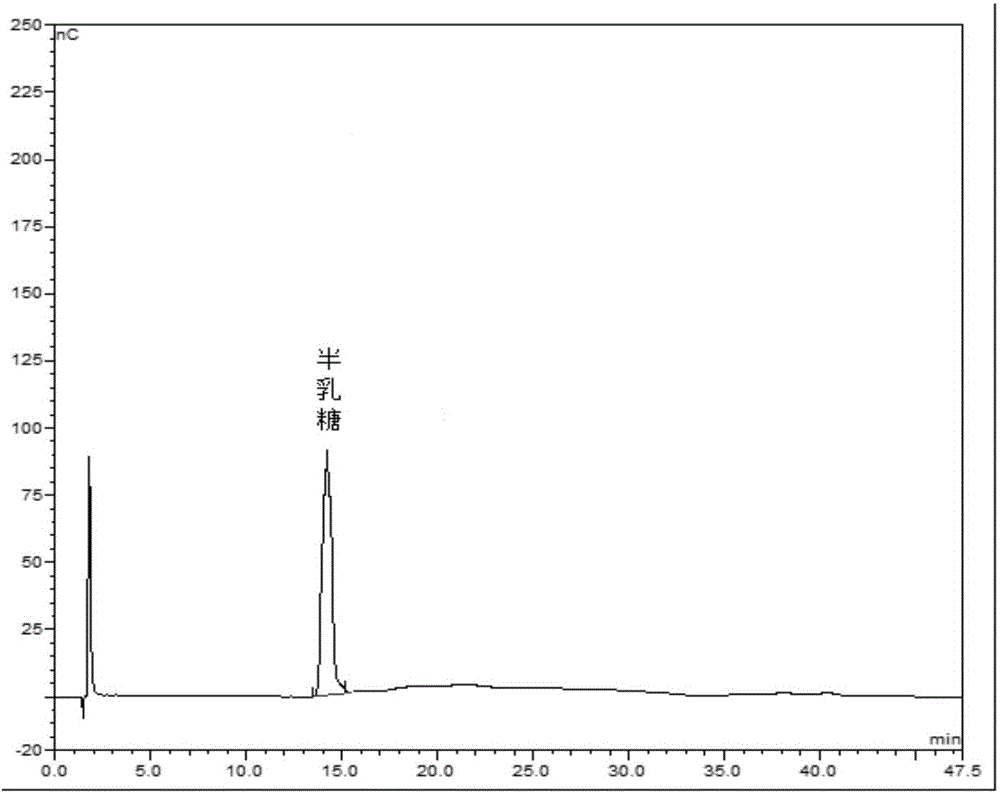

[0050] Add lactulose standard solution to the weighed blank sample of school drinking milk and shake well to prepare the lactulose spiked sample of this embodiment.

[0051] (1) Sample pretreatment

[0052] Pipette 50.00 mL of the student milk sample to be tested in a 250 mL Erlenmeyer flask, add 5 mL of potassium ferrocyanide solution with a concentration of 200 g / L, 5 mL of zinc sulfate solution with a concentration of 200 g / L, and 10 mL of buffer [0.34 mol / L Disodium hydrogen phosphate (Na 2 HPO 4 )+0.07mol / L sodium dihydrogen phosphate (NaH 2 PO 4 ), pH=7.5], each addition of reagents should be fully shaken, after all additions, let stand for 30 minutes, filter, discard the initial filtrate, and collect the filtrate.

[0053] Take 5 mL of the filtrate into a 10 mL volumetric flask, add 100 μL of β-D-galactosidase suspension, shake well, cover, and incubate at 50°C for 1 hour. Add 2.0mL of buffer solution [0.75mol / L triethanolamine hydrochloride (C 6 h 15 NO 3 ·HCl)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com