Method for preparing high-purity lactulose

A lactulose, high-purity technology is applied in the field of preparation of high-purity lactulose, and achieves the effects of reducing production costs, facilitating water-phase crystallization, and avoiding residual lactulitol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

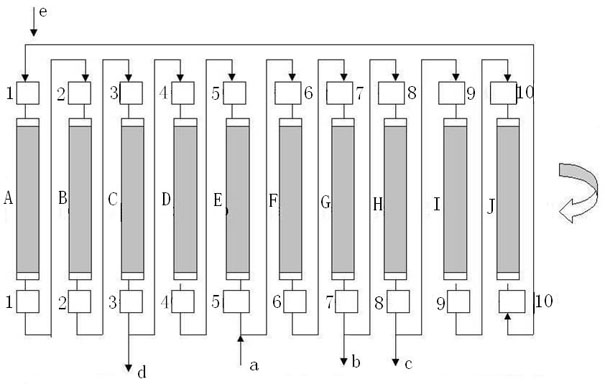

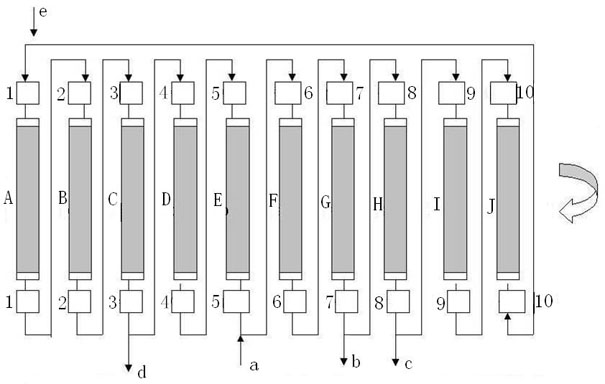

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 10kg of high-purity lactose, add deionized water to prepare a lactose solution with a concentration of 15%, add 1.8kg of boric acid, stir, adjust the pH to 11.0 with 30% NaOH solution, and react at 80°C for 120 minutes to obtain a transformation solution. Quickly take out and cool down to 50°C;

[0032] (2) Pump the converted liquid after cooling into a chromatographic column equipped with Amberlite IR-120Na strong acidic cation exchange resin, with a column inner diameter of 250mm and a height of 1500mm. °C, the pH of the suspension sugar solution is controlled at 4.5;

[0033] (3) Decolorize the sugar solution after separation treatment, using Norit 1240Plus granular activated carbon, the inner diameter of the activated carbon column is 250mm, the height is 1500mm, the filling height of activated carbon is 1100mm, the temperature is 77°C, and the flow rate is controlled at 3BV;

[0034] (4) The decolorized sugar solution is pumped into an Amberlite IRA96C r...

Embodiment 2

[0038] (1) Weigh 10kg of high-purity lactose, add deionized water to prepare a lactose solution with a concentration of 20%, add 1.8kg of boric acid, stir, adjust the pH to 11.0 with 30% NaOH solution, and react at 80°C for 120 minutes to obtain a transformation solution. Quickly take out and cool down to 58°C;

[0039] (2) Pump the converted liquid after cooling into a chromatographic column equipped with Amberlite IR-120Na strong acidic cation exchange resin, with a column inner diameter of 250mm and a height of 1500mm. °C, the pH of the suspension sugar solution is controlled at 6.5;

[0040] (3) Decolorize the sugar solution after the separation treatment, using Norit 1240Plus granular activated carbon, the inner diameter of the activated carbon column is 250mm, the height is 1500mm, the filling height of the activated carbon is 1100mm, the decolorization temperature is 78°C, and the flow rate of the feed liquid is controlled at 2BV;

[0041] (4) The decolorized sugar sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com