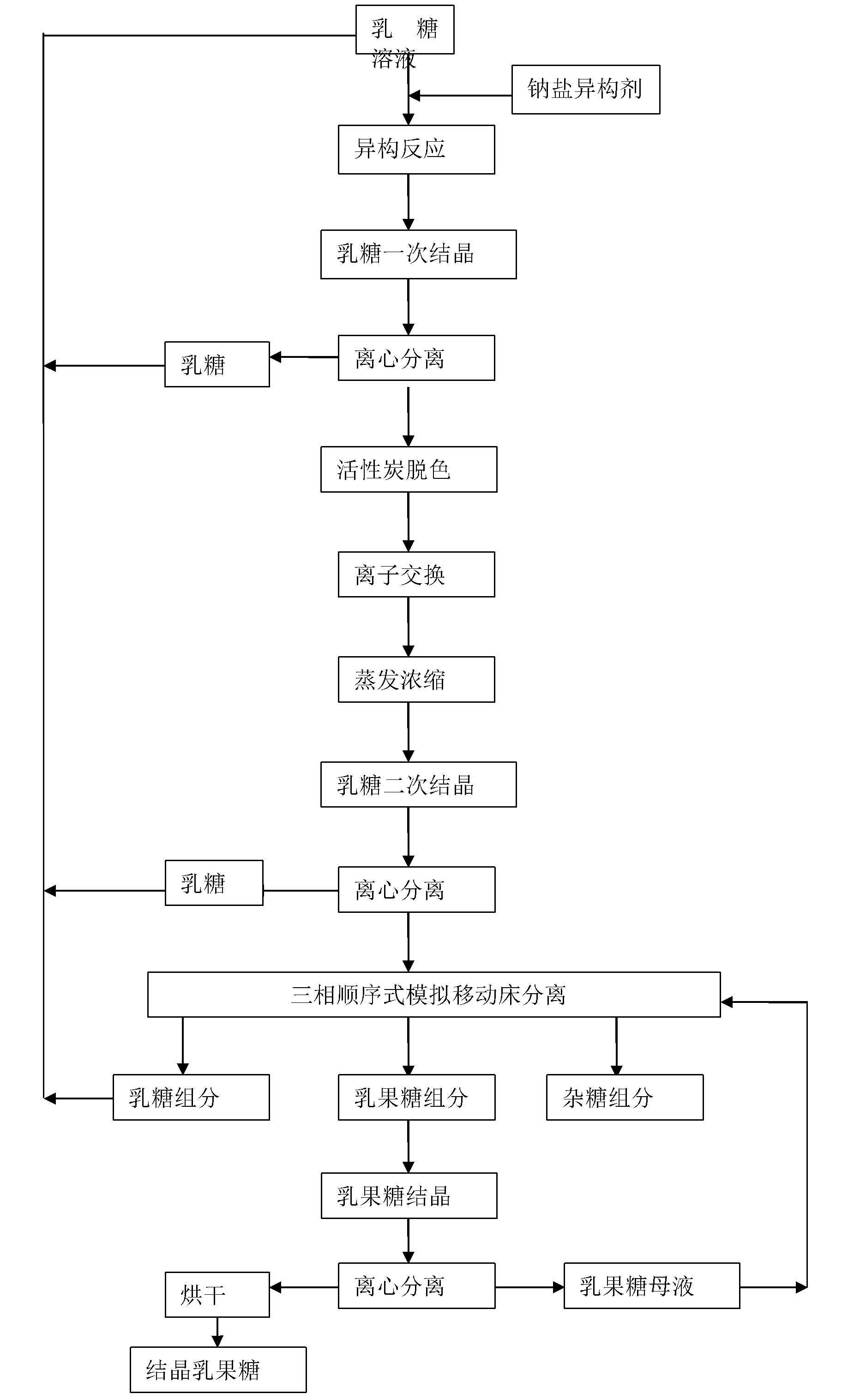

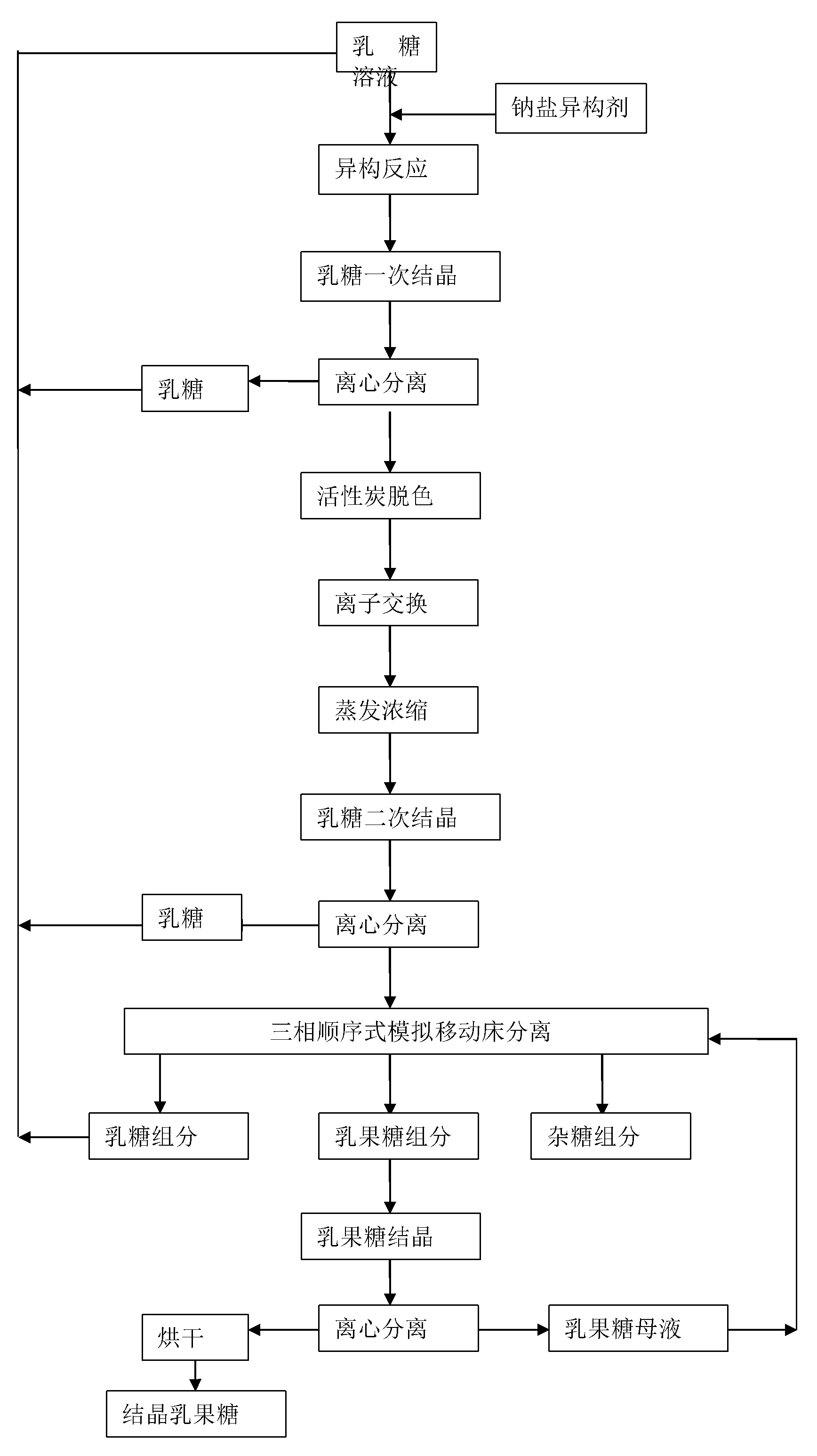

Production technique of crystalline lactulose

A production process and lactulose technology are applied in the production process field of crystalline lactulose, and can solve the problems of difficult removal of ethanol, easy water absorption, unsatisfactory industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Weigh 250kg of lactose, add water to make the lactose concentration 60%, then add 1.89kg of anhydrous sodium salt isomerization agent, then heat to 110°C, and maintain 110°C for isomerization for 2 hours, then cool to crystallize, centrifuge, Activated carbon decolorization, ion exchange to obtain a syrup with a lactulose content of 54.42%; evaporate the obtained lactulose syrup to a concentration of 65%, add lactose seed crystals at 1.0%, cool and crystallize at a speed of 2 to 4°C / h, and centrifuge Finally, lactulose syrup with a lactulose content of 79.86% was obtained; the concentration of the lactulose syrup obtained by the secondary crystallization was adjusted to 50%, and it entered the three-way sequential simulated moving bed at a speed of 3.0L / h. Separation was carried out under the condition of 17 minutes, and the content of lactulose in the lactulose component obtained was 91.22%; finally, the purified lactulose was concentrated to 85%, and lactulo...

Embodiment 2

[0030] Example 2: Weigh 250kg of lactose, add water to make the lactose concentration 50%, then add 6.3kg of anhydrous sodium salt isomerization agent, then heat to 90°C, and maintain 90°C for 4 hours, then cool to crystallize, centrifuge, Activated carbon decolorization and ion exchange to obtain a syrup with a lactulose content of 50.49%; evaporate the obtained lactulose syrup to a concentration of 75%, add lactose seed crystals at 0.1%, cool and crystallize at a speed of 6-8°C / h, and centrifuge Finally, lactulose syrup with a lactulose content of 77.25% is obtained; the concentration of the lactulose syrup obtained by secondary crystallization is adjusted to 40%, and it enters the three-way sequential simulated moving bed at a speed of 4.0L / h. Separation was carried out under the condition of 21 minutes, and the content of lactulose in the lactulose component obtained was 90.58%; finally, the purified lactulose was concentrated to 90%, and lactulose seed crystals were added ...

Embodiment 3

[0031]Example 3: Weigh 250kg of lactose, add water to make the lactose concentration 70%, then add 0.63kg of anhydrous sodium salt isomerization agent, then heat to 120°C, and maintain 120°C for 0.5h, then cool to crystallize and centrifuge , activated carbon decolorization, and ion exchange to obtain a syrup with a lactulose content of 52.19%; evaporate the obtained lactulose syrup to a concentration of 55%, add lactose seed crystals at 1.5%, and carry out cooling and crystallization at a speed of 4 to 6°C / h. After centrifugation, a lactulose syrup with a lactulose content of 71.86% was obtained; the concentration of the lactulose syrup obtained by secondary crystallization was adjusted to 60%, and entered into a three-way sequential simulated moving bed at a speed of 2.0L / h. Separation was carried out under the condition of 13 minutes, and the content of lactulose in the obtained lactulose component was 90.22%; finally, the purified lactulose was concentrated to 75%, and lact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com