Method used for pyrolyzing wet oxidation desulfurization mixed waste liquid in partial oxidation environment

A technology for wet oxidative desulfurization and oxidation of the environment, which is applied in the petroleum industry, combustible gas purification, chemical instruments and methods, etc. It can solve the problems that the mixed desulfurization waste liquid cannot be effectively treated, and the salt extraction product has a price but no market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

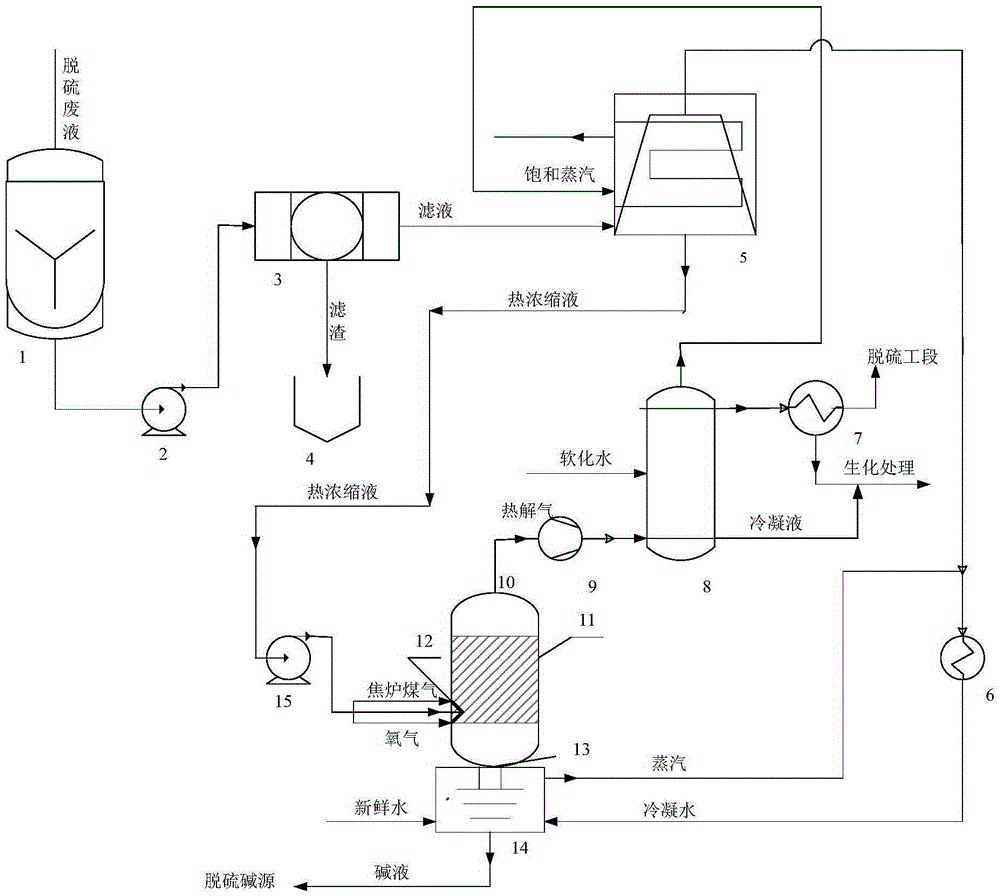

[0048] The desulfurization waste liquid used in this implementation case is a mixture of two desulfurization waste liquids produced by the wet desulfurization of the coking plant using the sodium-alkali method and the ammonium-alkali method. Take 500mL of the desulfurization waste liquid for the experiment. Among them, the content of sodium thiosulfate is about 13.51g, the content of sodium thiocyanate is about 13.67g, the content of ammonium thiosulfate is about 18.10g, the content of ammonium thiocyanate is about 20.15g, the content of suspended sulfur is 1.41g, and the content of CODcr is 65.38 g.

[0049] In the first step, 500mL of desulfurization waste liquid is filtered through rapid quantitative filter paper to obtain 5.41g of filtrate;

[0050] The second step is to evaporate and preheat the above filtrate. The heat source is saturated steam from the waste heat boiler. The vacuum degree of evaporation is 0.057MPa to obtain 250mL of 85°C concentrated liquid; the genera...

Embodiment example 2

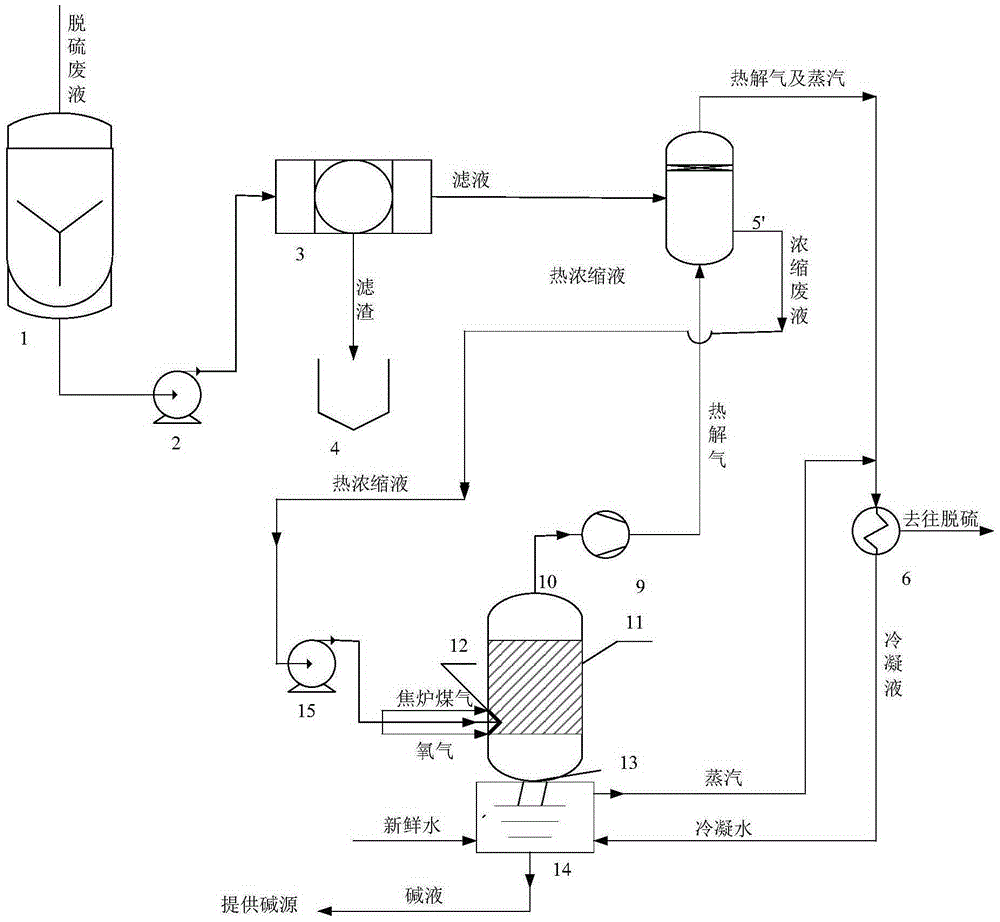

[0056] The desulfurization waste liquid used in this implementation case is a mixture of two desulfurization waste liquids produced by the wet desulfurization of the coking plant using the sodium-alkali method and the ammonium-alkali method. Take 500mL of the desulfurization waste liquid for the experiment. Wherein the sodium thiosulfate content is about 13.51g, the sodium thiocyanate content is about 13.67g, the ammonium thiosulfate content is about 18.10g, the ammonium thiocyanate content is about 20.15g, and the suspended sulfur is 1.41g.

[0057] In the first step, 500mL of desulfurization waste liquid is filtered through rapid quantitative filter paper to obtain 5.39g of filtrate;

[0058] The second step is to evaporate and preheat the above filtrate. The heat source is the high-temperature pyrolysis gas from the pyrolysis reactor. The pyrolysis gas enters the preheater from the bottom of the evaporation preheater to perform direct contact heat exchange with the desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com