One-way radiating furnace tube ethane cracking furnace

A technology of ethylene cracking furnace and radiant furnace tube, which is applied in the direction of cracking, hydrocarbon cracking to hydrocarbon, non-catalytic thermal cracking, etc. It can solve the problems of short operation period of cracking furnace, blockage of radiant furnace tube, large occupied area, etc., and achieves Effects of reducing impact, reducing degree of bending, and preventing secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

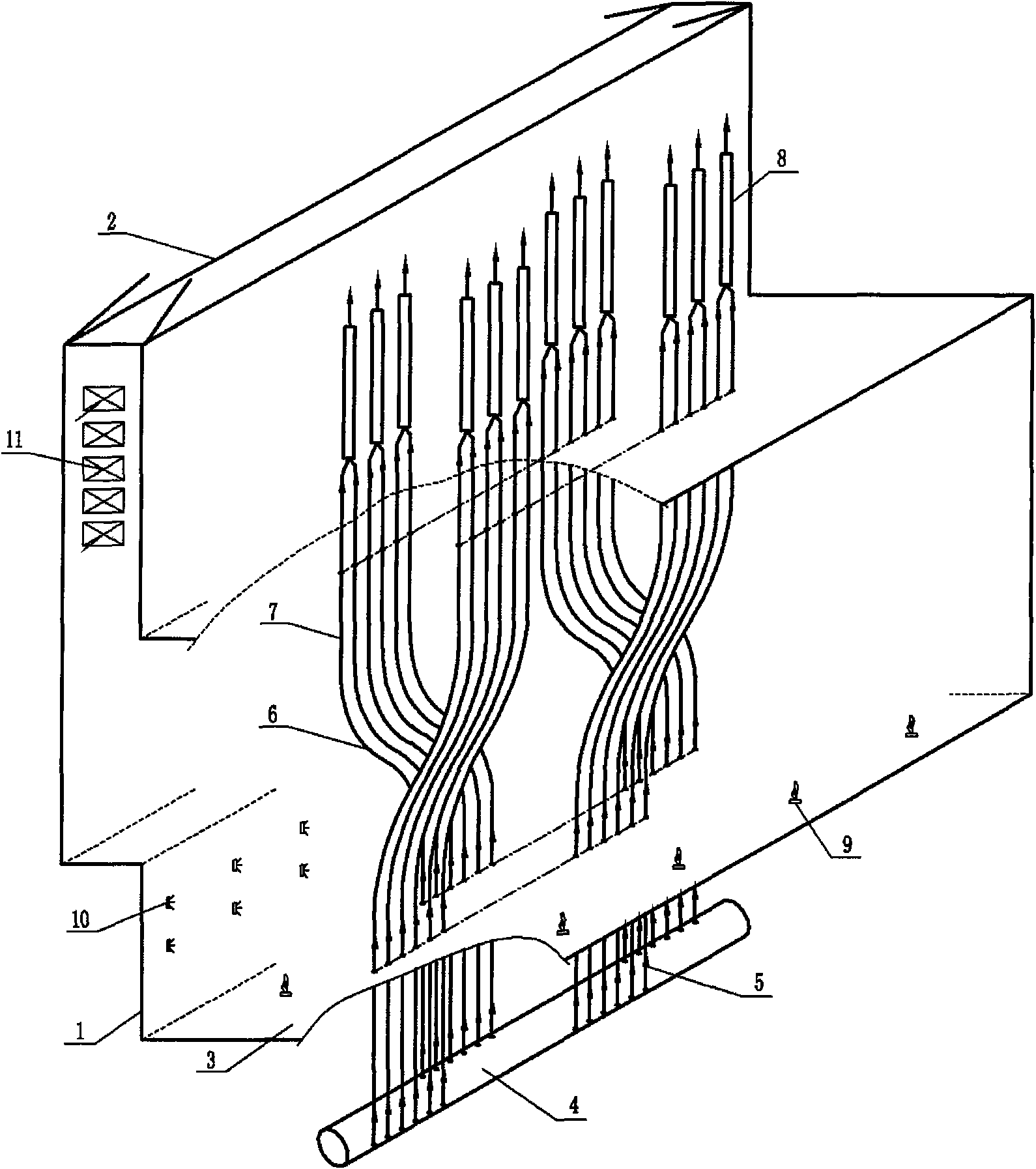

[0030] A single-pass radiation furnace tube ethylene cracking furnace, its structure is as follows figure 1 As shown, the cracking furnace comprises a radiation section 1, a convection section 2, a manifold 4, a distribution pipe 5 and a quench boiler 8, the radiation section 1 is arranged on the left side of the cracking furnace, and the radiation section 1 is provided with a radiation chamber 3, and the radiation chamber 3 is equipped with a radiant furnace tube, a bottom burner 9 and a side wall burner 10. The radiant furnace tube is a single-pass furnace tube, which is composed of a bent tube 6 and a straight tube 7. The bent tube 6 and the straight tube 7 are equal-diameter tubes. The inner diameter of the two is the same, which is 35mm. The bending radius of the elbow 6 is 300mm, and the bending direction is parallel to the surface of the tube row. 2 times of the furnace tube spacing between adjacent groups is 2 times of the inner diameter of the radiation furnace tube, ...

Embodiment 2

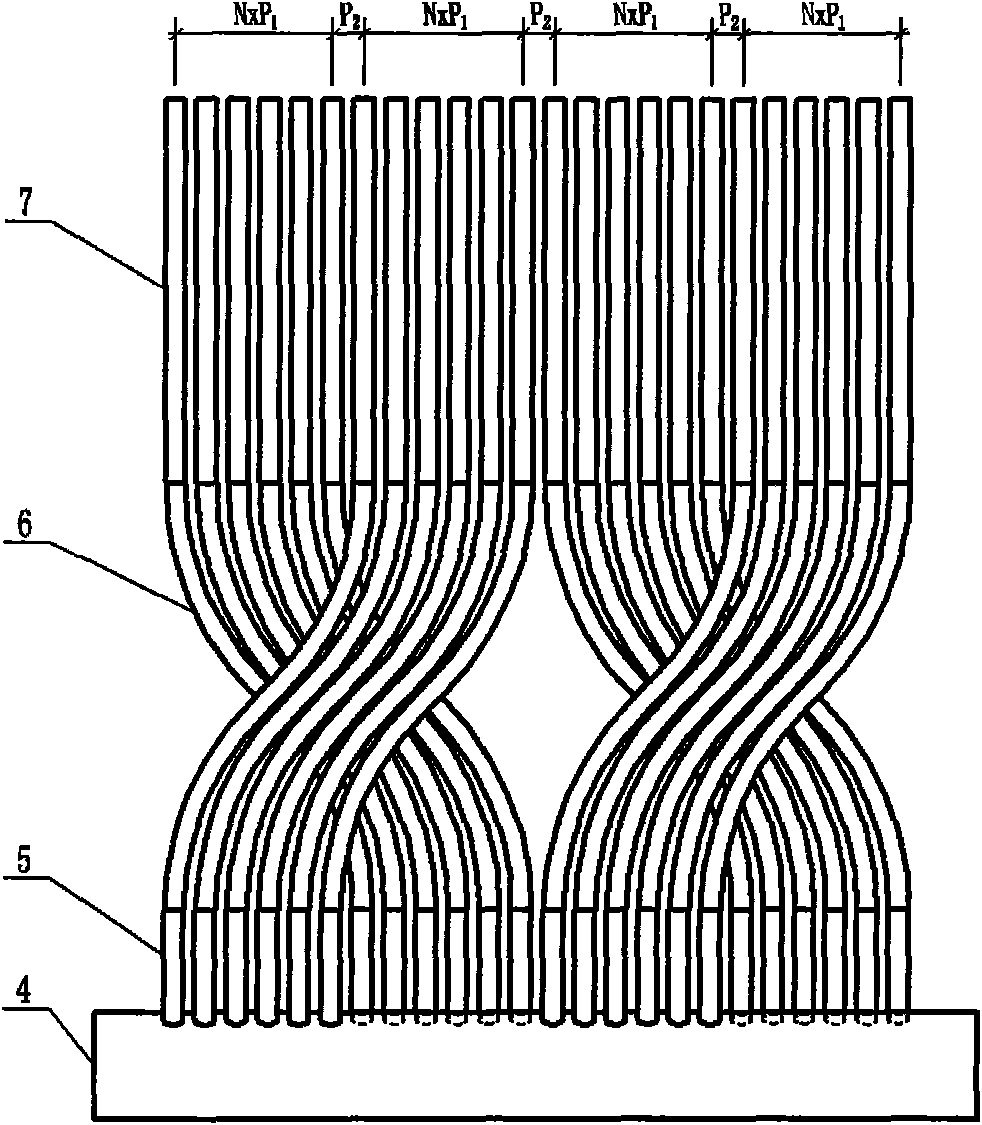

[0033] A single-pass radiation furnace tube ethylene cracking furnace, the arrangement of the radiation furnace tubes of the cracking furnace is as follows Figure 2a-2b As shown, 96 radiation furnace tubes are arranged in each radiation chamber 3, and every 6 radiation furnace tubes form a group, and every 4 groups form a large group, and each radiation room has four groups of such radiation furnace tubes. If there is only one such radiation chamber in the radiation section, the ethylene production capacity of the cracking furnace can reach 50,000 to 60,000 tons / year; if there are two such radiation chambers in the radiation section, the ethylene production capacity of the cracking furnace can reach 100,000 to 120,000 tons / year. Several important dimensions of the cracking furnace are: the inner diameter of the radiation furnace tube D in = 40mm, the number of radiation furnace tubes forming a group N = 6, the distance between two rows of furnace tubes L 1 =300mm, the furna...

Embodiment 3

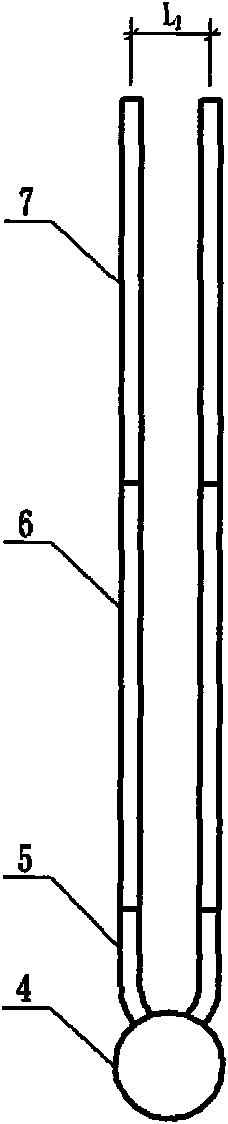

[0035] A single-pass radiation furnace tube ethylene cracking furnace, the cracking furnace includes a radiation section, a convection section, a manifold, a distribution pipe and a quench boiler, and the arrangement of the radiation furnace tubes of the cracking furnace is as follows: Figure 3a~3b As shown, the radiant section is set on the left side of the cracking furnace. There is a radiant room in the radiant section. The radiant room is equipped with a radiant furnace tube, a bottom burner and a side wall burner. The curved pipe and the straight pipe are equal-diameter pipes. The inner diameter of the two is the same, which is 60mm. The bending radius of the curved pipe is 2000mm. Form a large group, the distance between the furnace tubes in the group is 5 times the inner diameter of the radiation furnace tube, the distance between the furnace tubes between adjacent groups is 5 times the inner diameter of the radiation furnace tube, the radiation furnace tubes are arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending radius | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com