Coal microwave dry distillation equipment and coal microwave dry distillation treatment method thereof

A microwave and coal technology, applied in coal processing equipment, coal microwave dry distillation equipment and coal microwave dry distillation treatment field, can solve the problems of easy secondary reaction, inability to carry out the whole process, and low heating efficiency, so as to improve microwave heating efficiency, Easy to operate and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

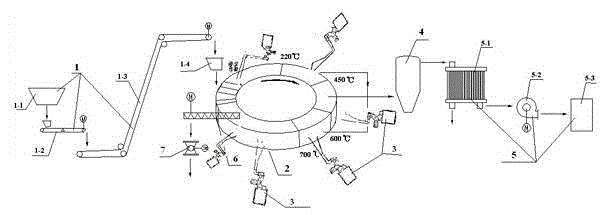

[0034] Such as figure 1 shown. A coal microwave dry distillation equipment, which includes a feed system (1), a microwave dry distillation kiln (2) connected to the feed system (1), and a microwave generator (3) installed around the microwave dry distillation kiln (2) , the dust removal system (4) connected with the microwave retort furnace (2), the tar and gas cooling collection system (5) connected with the dust removal system (4), the tailing cooling system connected with the microwave retort furnace (2) ( 6), the discharge system (7) connected with the tailing cooling system (6);

[0035] The feeding system (1) includes a material receiving bin (1-1), a batching belt scale (1-2) connected to the feeding bin (1-1), and a batching belt scale (1-2) connected A belt with a large inclination angle (1-3), a vibrating distribution machine (1-4) connected with the belt with a large inclination angle (1-3);

[0036] The furnace body of the microwave retort furnace kiln (2) is ci...

Embodiment 2

[0045] A coal microwave dry distillation treatment method, which comprises the following steps:

[0046] Step 1. Transport the coal to the receiving bin (1-1), and transport the coal to the large-inclination belt (1-3) through the batching belt scale (1-2), and then transport it through the large-inclination belt (1-3) Go to the vibrating cloth machine (1-4) for cloth;

[0047] Step 2, the coal rotates in the microwave retort kiln (2), and the coal material is heated by 6 microwave generators (3) installed on the microwave retort kiln (2);

[0048] Step 3. The highly attached products obtained from heating the coal materials are guided by the fan (5-2) and first enter the dust removal system (4) for dust removal of the flue gas, and then enter the tar and gas cooling collection system (5) for tar and gas to collect;

[0049] Step 4. The heated coal material comes out of the microwave carbonization furnace (2) through the high-temperature water-cooled screw machine in the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com