Method for processing inferior heavy oil

A low-quality heavy oil and heavy oil technology, which is applied in the multi-stage series-connected refining and cracking process treatment, granular/powder fuel gasification, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

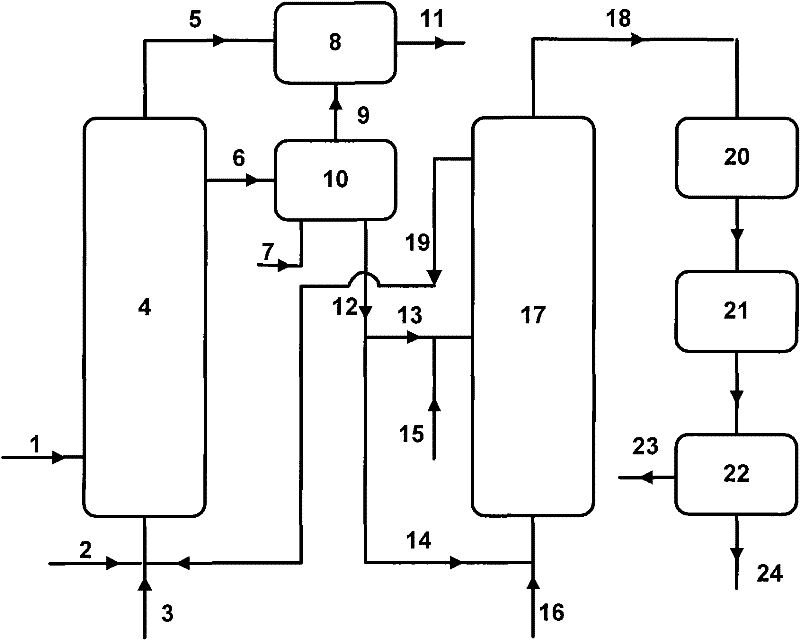

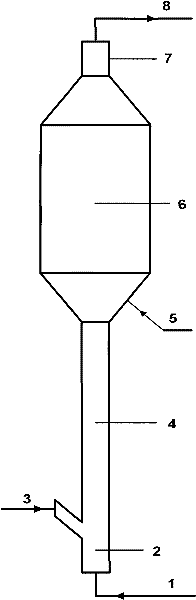

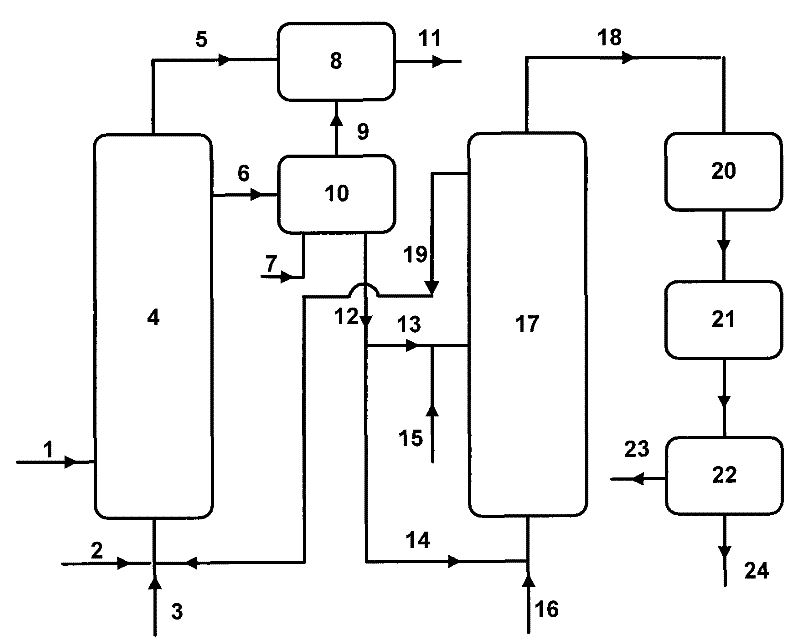

Method used

Image

Examples

Embodiment 1

[0042] Mix USY molecular sieve, silicon-aluminum matrix, silicon-based binder with a small amount of deionization in a mass ratio of 10:55:35, mix and beat, spray dry, shape, and roast to obtain contact agent A. The initial microreaction activity of contact agent A was 44. The residual oil raw material contacts and reacts with the contact agent A in the fluidized bed reactor, the deactivated contact agent is separated from the product oil and gas, and the product oil and gas are fractionated to obtain dry gas, distillate oil and other products, the reaction conditions and product distribution of the contact reaction As shown in table 2.

[0043] The content of coke on the spent agent A was 2.90% by weight. The spent agent A at a temperature of 470°C was stripped with steam for 30 minutes. The to-be-generated agent A is divided into two streams, which are sent to the gasifier in stages with gasification agent I and gasification agent II with different oxygen contents, and the...

Embodiment 2

[0052] The acid clay that has been pickled, roasted and sieved is sieved with a particle size range of 20-100 μm, and used as contact agent B. The initial microreaction activity of contact agent B is 8. The residual oil raw material contacts and reacts with the contact agent B in the fluidized bed reactor, the deactivated contact agent is separated from the product oil and gas, and the product oil and gas are fractionated to obtain dry gas, distillate oil and other products, the reaction conditions and product distribution of the contact reaction As shown in table 2.

[0053]The content of coke on the spent agent B was 3.07% by weight. The spent agent B at a temperature of 475°C was stripped with water steam for 30 minutes. The raw agent B after stripping is divided into two streams, which are respectively sent to the gasifier in stages with gasification agent I and gasification agent II with different oxygen contents, and gasification reaction occurs. The specific gasifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com