Preparation method of hierarchically porous zeolite molecular sieve

A zeolite molecular sieve and multi-stage pore technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., to achieve the effects of simple and easy methods, preventing excessive desilication, and improving diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

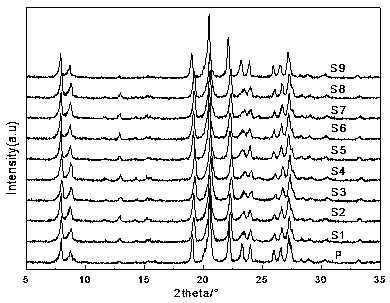

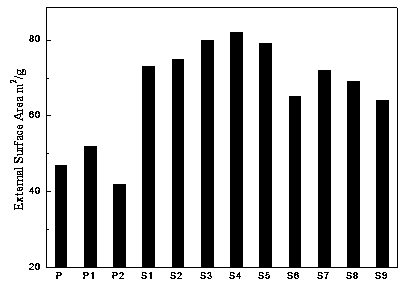

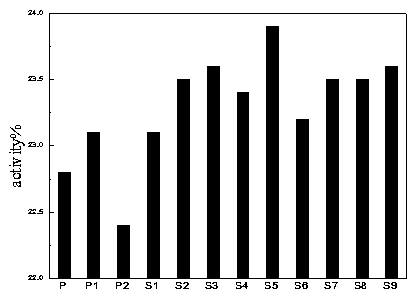

[0029] Take 10g EU-1 (SiO 2 / Al 2 o 3 molar ratio=80:1) Molecular sieve raw powder, according to the 3°C / min temperature rise program to 370°C for 5h, weigh 5g of the sample after the roasting, according to the liquid-solid weight ratio of 20:1 and 1.0mol / L hydrochloric acid solution After mixing and stirring evenly, treat at 150°C for 24h. After the reaction is over, filter and wash until neutral, and dry at 120°C for 12h; mix the dried sample with 0.8mol / L tetramethylammonium hydroxide solution according to the liquid-solid weight ratio of 20 : 1 mix, stir evenly, add 1gCTAB, react at 120°C for 24h, filter and wash to neutral pH, dry at 120°C for 12h, and bake at 550°C for 300 minutes to obtain a hierarchically porous EU-1 molecular sieve product, remember S1.

Embodiment 2

[0031] Take 10g EU-1 (SiO 2 / Al 2 o 3 molar ratio=30:1) Molecular sieve raw powder, roasted at 550 °C for 3 hours according to the temperature rise program of 5 °C / min, weighed 5 g and 0.8 mol / L of the sample after roasting and mixed with hydrochloric acid solution according to the liquid-solid weight ratio of 10:1 , treated at 120°C for 18 hours, the reaction was completed, the pH was filtered and washed to neutral, and dried at 120°C for 12 hours; the dried sample was mixed with 1.0mol / L ammonia solution according to the liquid-solid weight ratio of 30:1, and 3gCTAB was added after stirring evenly. React at 150°C for 30 hours, filter and wash until neutral, dry at 120°C for 12 hours, and calcine at 550°C for 300 minutes to obtain a hierarchically porous EU-1 molecular sieve product, remember sample S2.

Embodiment 3

[0033] Take 10g EU-1 (SiO 2 / Al 2 o 3 molar ratio=40:1) Molecular sieve raw powder, according to the 4°C / min temperature rise program to 450°C for 4.5h, weigh 5g and 0.1mol / L of the sample after the roasting and mix with acetic acid solution according to the liquid-solid weight ratio of 15:1 Mix and treat at 130°C for 16 hours. After the reaction is completed, filter and wash the pH to neutral, and dry at 120°C for 12 hours; mix the dried sample with 0.5mol / L tetraethylammonium hydroxide solution according to the liquid-solid weight ratio of 25:1, After stirring evenly, add 3g of CTAB, react at 140°C for 36h, filter and wash until neutral, dry at 120°C for 12h, and calcined at 550°C for 300 minutes to obtain a hierarchically porous EU-1 molecular sieve product, remember sample S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com