Composite material containing double-pore structure Y-type zeolite, and preparation method thereof

A composite material and pore structure technology, which is applied in the directions of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of low feed utilization rate, large recovery and processing capacity of mother liquor, and low crystallinity of synthetic products. achieve the effect of avoiding secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides the preparation method of above-mentioned composite material, comprises the following steps:

[0028] (1) Kaolin is roasted and dehydrated at 500-890° C., and pulverized to obtain metakaolin powder with a particle size of less than 2 μm and no less than 50% of it;

[0029] (2) Add silicon source, directing agent, sodium hydroxide solution and water to metakaolin powder to make a ratio of (1-2.5)Na 2 O:Al 2 o 3:(4-9)SiO 2 :(40-100)H 2 The reaction raw material mixture of O, wherein the weight ratio of directing agent and metakaolin is 0.1-1.0;

[0030] (3) The reaction raw material mixture is crystallized at 50-98° C. with programmed temperature increase in stages and variable speed, filtering, washing and drying to obtain a Y-type zeolite composite material product with a double-pore structure.

[0031] In the preparation method provided by the present invention, the kaolin mentioned in the step (1) includes halloysite, kaolin, h...

Embodiment 1

[0046] The preparation of directing agent: get 250 grams of sodium silicate solutions (containing 20.05% by weight of SiO 2 , 6.41 wt% Na 2 (0), slowly add 120 grams of sodium metaaluminate solution (containing 3.15% by weight of Al) under rapid stirring at 30°C 2 o 3 , 21.1 wt% Na 2 O), stirred for 1 hour, and aged at 26° C. for 24 hours to obtain a directing agent. The composition of the directing agent is 16Na 2 O:Al 2 o 3 : 15 SiO 2 : 320H 2 O (the same below).

[0047] Kaolin with an average particle size of 4 μm (Suzhou, Yangshan brand, China Kaolin Company, crystal content is 80% by weight) was roasted at 800 ° C for 4 hours to obtain metakaolin powder, which was pulverized to make a powder with a particle size of less than 2.0 μm. Less than 50% metakaolin powder.

[0048] Get 500 grams of pulverized metakaolin powder, add 2500 grams of sodium silicate solution (containing 20.05% by weight of SiO 2 , 6.41 wt% Na 2 (2), 200 grams of directing agent, 80 grams ...

Embodiment 2

[0055] Get the metakaolin powder after the crushing of 500 gram embodiment 1, add 2500 gram sodium silicate solution (containing the SiO of 20.05% by weight) under stirring 2 , 6.41 wt% Na 2 (0), 200 grams of directing agent, 120 grams of concentration is 30% by weight of sodium hydroxide solution, 1000 grams of deionized water. Raise the temperature to 75°C and stir for 2 hours at a stirring speed of 1000 rpm, and keep the temperature at 75°C for 8 hours; raise the temperature to 90°C with stirring, and crystallize at a constant temperature for 28 hours at a stirring speed of 200 rpm. After the crystallization was completed, the crystallization tank was cooled, filtered, and washed with water until the pH value of the washing solution was less than 10. Drying at 120° C. for 2 hours gave composite material Y-2.

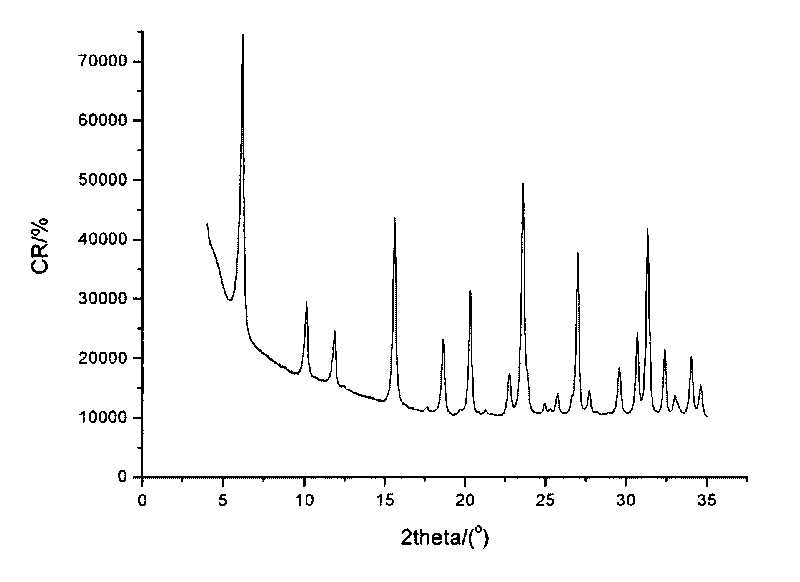

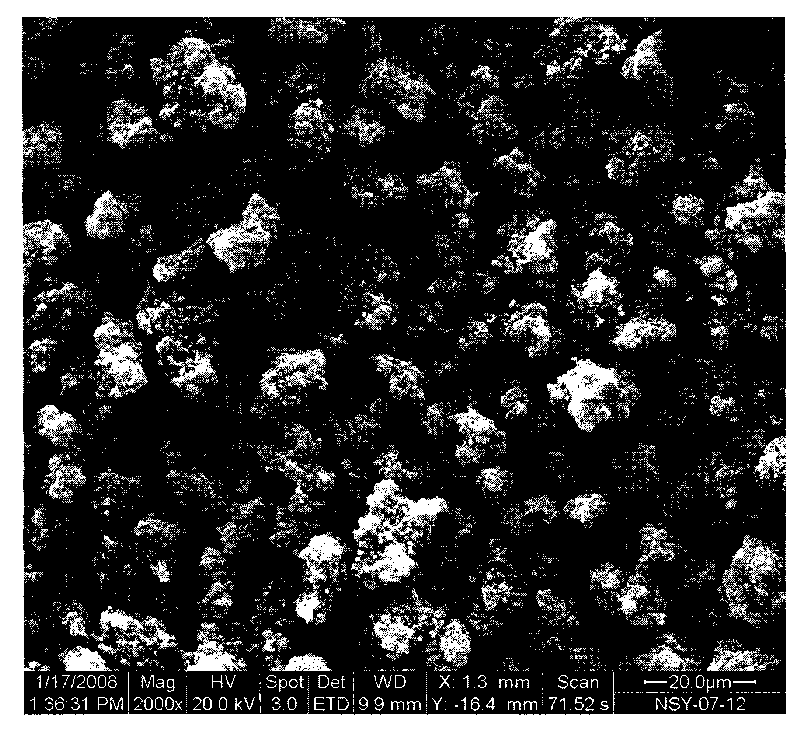

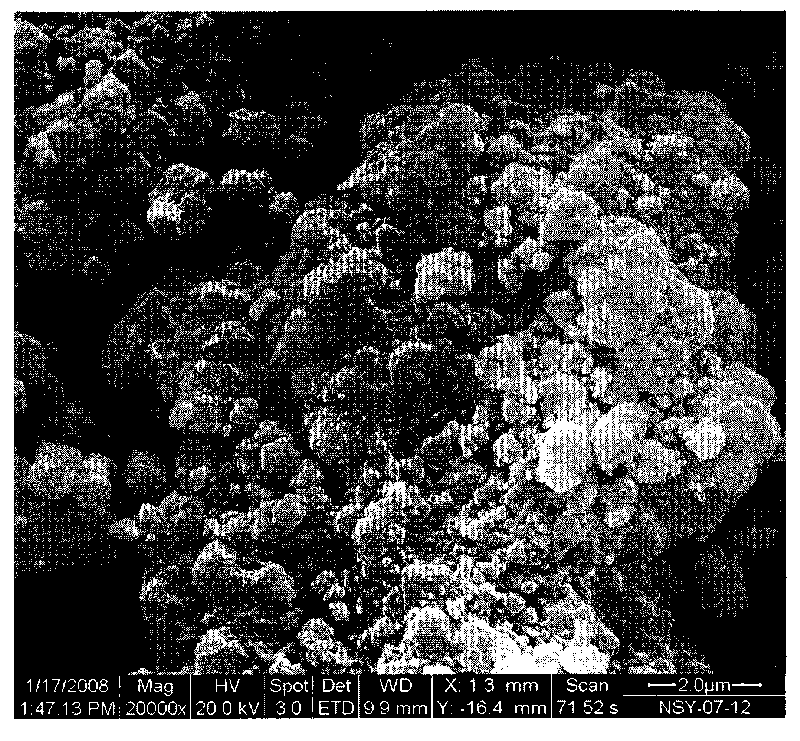

[0056] Y-2 has figure 2 , 3 The characteristics of X-ray diffraction are determined, wherein the NaY content is 80.4% by weight, the unit cell constant is 2.472nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com