Mild pyrolysis method for preparing liquid hydrocarbon through waste polyolefin

A technology for waste polyolefins and liquid hydrocarbons, applied in the field of mild cracking, can solve the problems of low liquid yield, increased catalytic cracking section, and high gas yield, avoiding unfavorable secondary reactions, reducing melt viscosity, and low cracking temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The mild cracking of embodiment 1 polyolefin (HDPE, HDPE / PP)

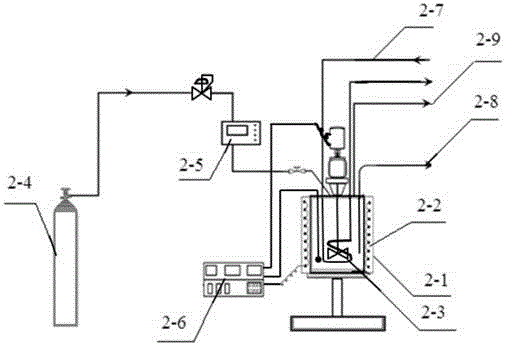

[0036] Such as figure 1 Shown, a kind of mild cracking method that utilizes waste polyolefin to produce liquid hydrocarbon, described method comprises the following steps:

[0037] 1) Pre-treatment: After separating and removing components that are easy to release harmful gases from waste polyolefin plastics, the waste polyolefin plastics are crushed and granulated to obtain polyolefin particles with a particle size of 2-4 mm as cracking raw materials;

[0038] 2) Wax production: After adding the waste polyolefin particles prepared in step 1) to the wax production device, seal the wax production device and purge the air with an inert gas to ensure that the cracking reaction is carried out in an inert atmosphere, and set the reaction temperature range When the temperature is 300-380°C, start stirring and start heating, the stirring rate is 200-400rpm, the heating rate is 2-20°C / min, and the set reaction temp...

Embodiment 2

[0066] The mild cracking of embodiment 2 waste polyolefin (HDPE / PP=50 / 50)

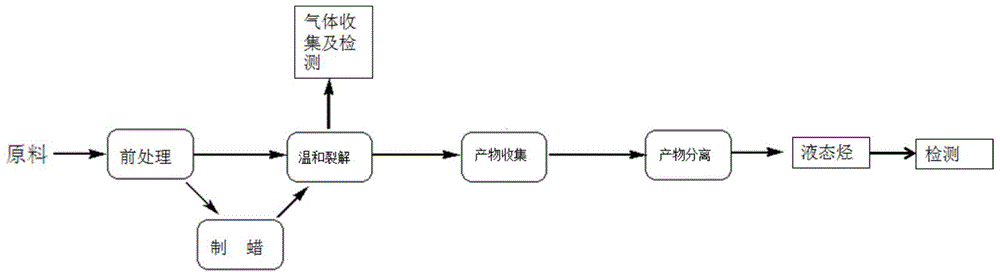

[0067] Such as figure 2 Shown, a kind of mild cracking method that utilizes waste polyolefin to produce liquid hydrocarbon, described method comprises the following steps:

[0068] 1) Using mixed waste polyolefin particles with a particle size of 2 to 5 mm (50 / 50 waste HDPE / PP, black, provided by Longda Plastic Products Factory in Xiongxian County, Hebei Province) as a cracking raw material;

[0069] 2) Wax making: After adding the waste polyolefin particles in step 1) to the wax making device, seal the wax making device and blow out the air with an inert gas to ensure that the cracking reaction is carried out in an inert atmosphere. The reaction temperature range is set to 300 ~380°C, start stirring and start heating, the stirring rate is 200~400rpm, the heating rate is 2~20°C / min, and the set reaction temperature is reached. After the reaction is completed, stop heating and cool down to obtain wast...

Embodiment 3

[0080] 1) Use waste polyolefin (HDPE / PP=50 / 50) with a particle size of 0.1-200mm as the cracking raw material;

[0081] 2) Heating the waste polyolefin above at a heating rate of 4°C / min, cooling down immediately when the temperature reaches 380°C to obtain a white solid waste polyolefin wax;

[0082] 3) Heat up waste polyolefin, waste polyolefin / waste polyolefin wax = 2:1, and waste polyolefin wax to 430°C at a heating rate of 4°C / min, and maintain this temperature for 30min or 40min, collect The gaseous product at this temperature, the yield of gaseous product is shown in Table 8.

[0083] Table 8 Yield list of waste HDPE / PP mild cracking products

[0084]

[0085] It can be seen from Table 8 that when HDPE and the produced wax are mixed and cracked (mass ratio is 2:1), the yield of the obtained gaseous product is about 3% higher than the theoretical yield, indicating that after the waste polyolefin is made into wax It has a very good function of promoting the cracking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com