Thermal cracking simulation experiment device and method

A simulated experimental device, thermal cracking technology, applied in the field of thermal cracked simulated experimental devices, can solve the problems of disassembly, inconvenient maintenance operation, low cooling efficiency, increased residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

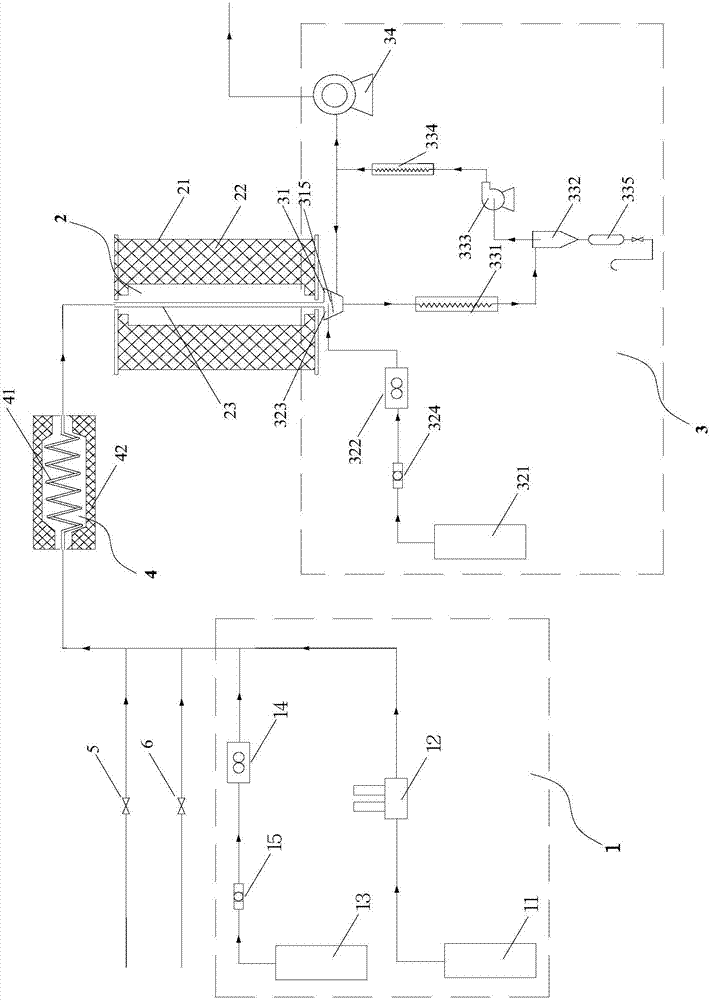

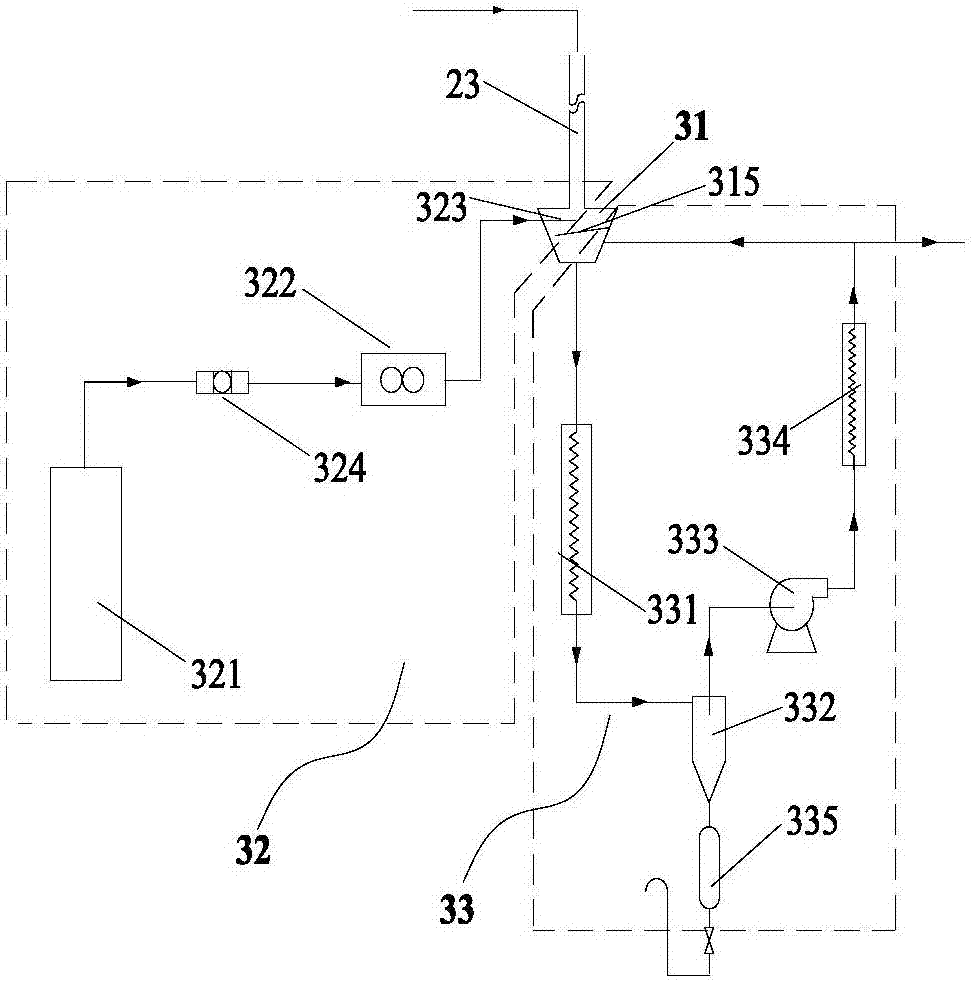

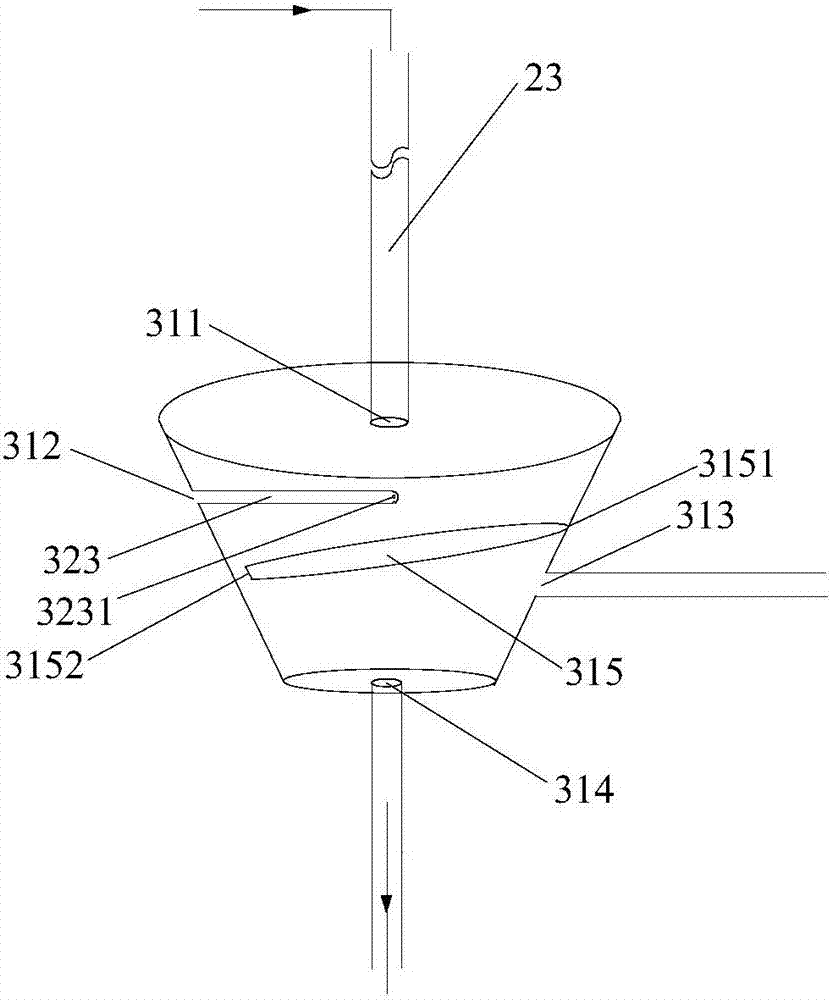

[0064] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0065] see Figure 1-Figure 4 , figure 1 It is a schematic structural diagram of a pyrolysis simulation experiment device according to an embodiment of the present invention. figure 2 It is a structural schematic diagram of a product quenching recovery device according to an embodiment of the present invention. image 3 It is a structural schematic diagram of the connection relationship between the mixing quench cooler, the quench water injection pipe and the feed inlet of the circulating gas product according to an embodiment of the present invention. Figure 4 It is a schematic diagram of an arcuate metal baffle according to an embodiment of the present invention. The thermal cracking simulation experiment device of the present invention comprises a raw material feeding device 1 , a cracking furnace 2 and a product quenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com