Flow guiding cyclone type biomass pyrolysis reactor

A technology of biomass pyrolysis and reactor, which is applied in the direction of biofuel, special carbonization, direct heating, etc., can solve the problems of inaccurate control of residence time, affecting the quality and yield of bio-oil, and low heat transfer rate. Achieve the effect of enhancing the mixing heat transfer effect, reducing site restrictions, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

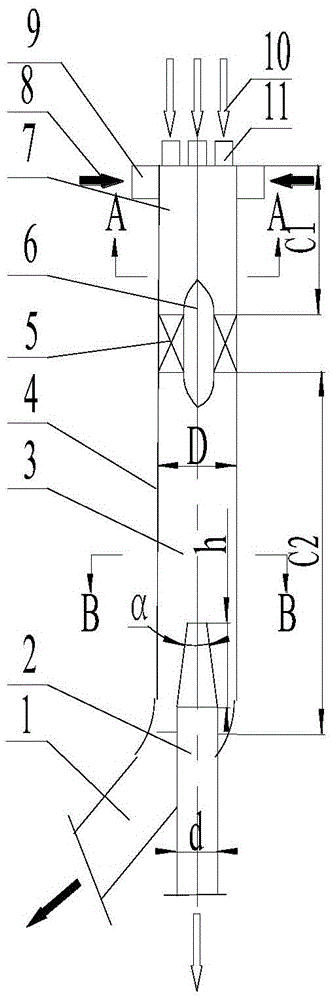

[0027] Below in conjunction with accompanying drawing, the present invention will be further described.

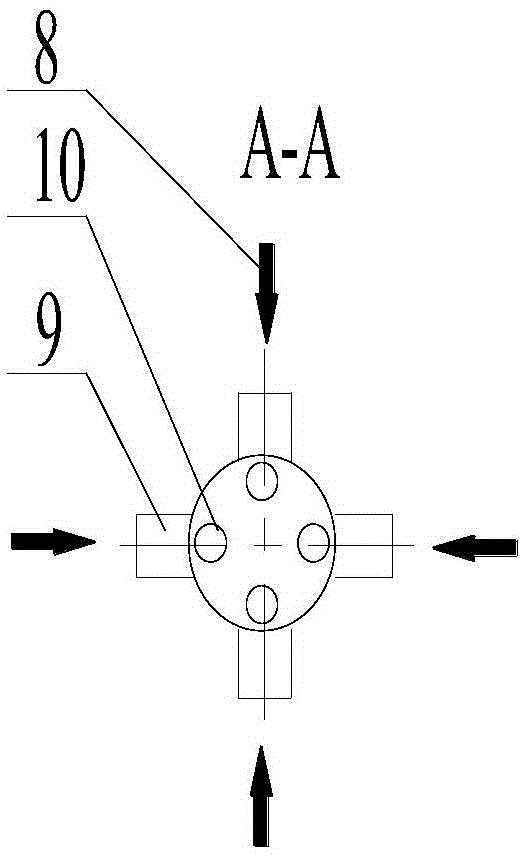

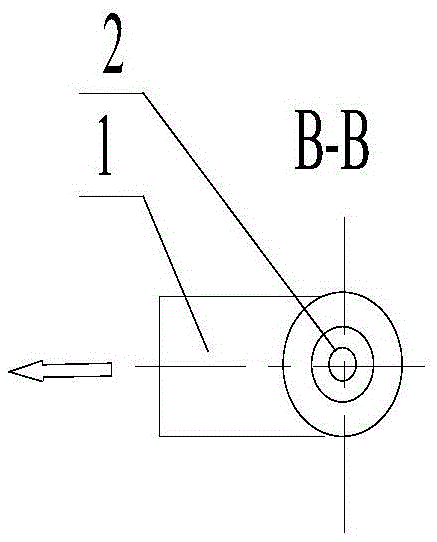

[0028] combine figure 1 , 2 , 3, a kind of diversion cyclone type biomass pyrolysis reactor of the present invention, comprises shell (4), diversion cone (6), guide vane (5), biomass feed pipe (9), heat carrier Feed pipe (11), dust cone (1) and exhaust pipe (2).

[0029] The heat carrier feed pipe (11) is evenly installed on the top circumference of the contact pre-reaction zone (7), and its axis is at an angle of 0 to 45° with the vertical direction, and the biomass feed pipe (9) is installed on the contact pre-reaction area (7). The upper cylindrical surface of the pre-reaction zone (7) is inserted into the upper cylindrical section in contact with the pre-reaction zone (7), and penetrates with the cylindrical surface. The direction of rotation must be consistent, and the angle between the central axis of the biomass feed pipe (9) and the horizontal direction 0°~45°. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com