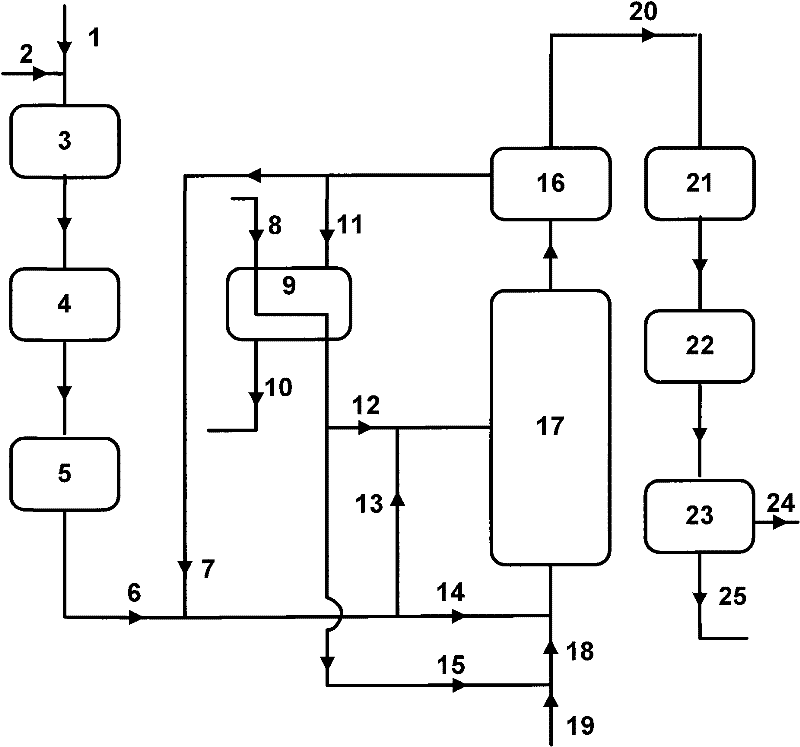

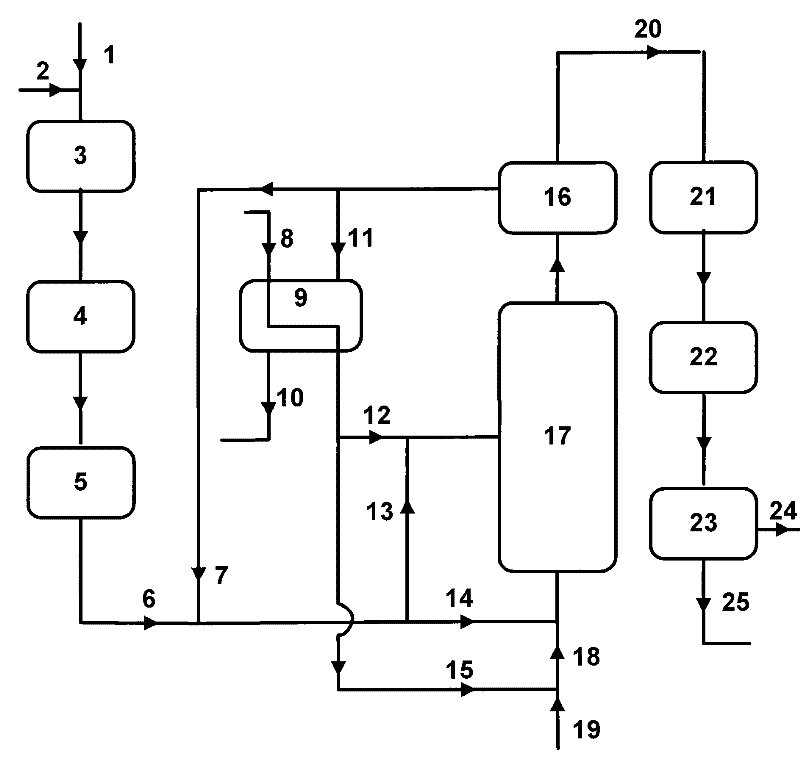

Preparation method of synthesis gas by gasifying carbonaceous materials

A synthesis gas and carbon-based technology, applied in the direction of granular/powdered fuel gasification, bulk chemical production, etc., can solve the problems of reducing the efficiency of the gasification process, and meet the requirements of high heat utilization rate, strong adaptability, and equipment low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

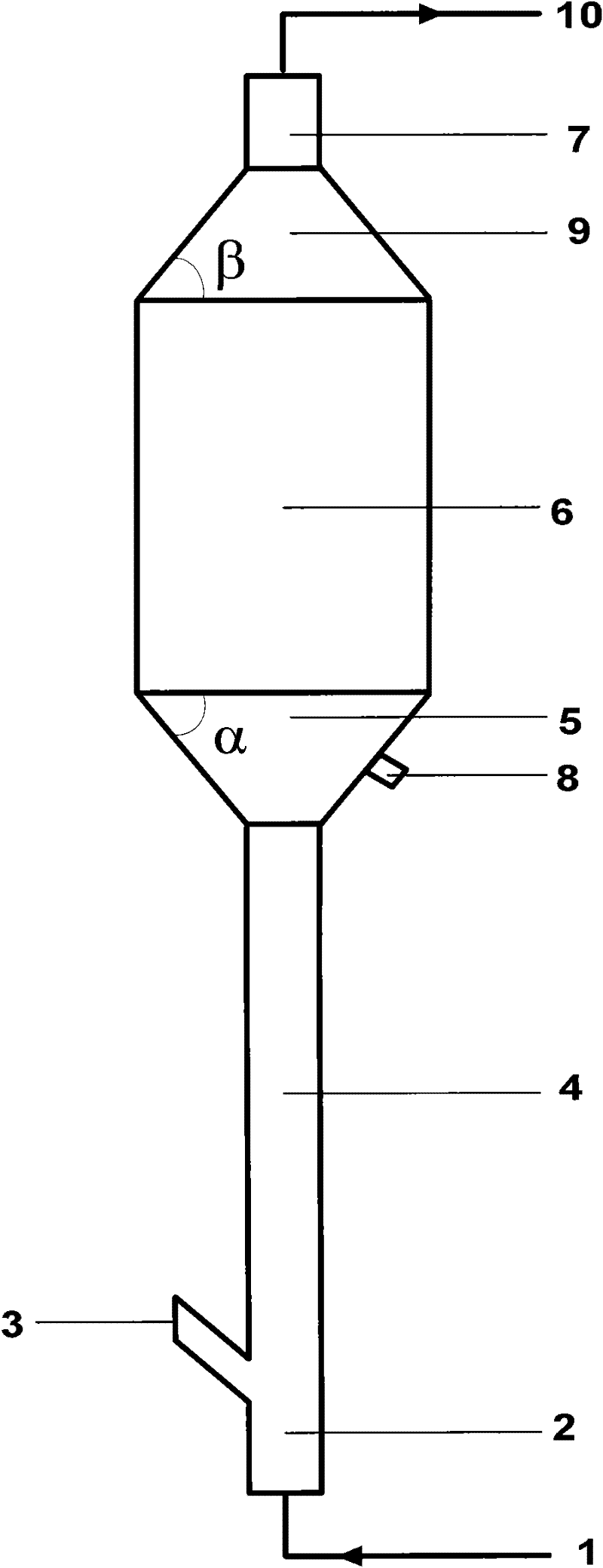

Embodiment 1

[0039] In this example, delayed coking petroleum coke was used as the carbonaceous material, the properties of which are listed in Table 1, and calcium carbonate was used as the gasification catalyst. Petroleum coke and calcium carbonate (analytically pure) were mixed uniformly at a mass ratio of 95:5, dried at 150°C for 10 minutes, and then pulverized and ground to a particle size range of 10-200 mesh (0.075-2.00mm). The above-mentioned solid particles are divided into two streams according to a certain ratio, and the mixed gas composed of oxygen + water vapor containing different oxygen content is respectively entered into different reaction zones of the gasifier for gasification reaction. At the top of the gasifier, the reaction residual solids (ash) are separated from the gaseous products by cyclone technology. Part of the residual solids are mixed with fresh petroleum coke powder, and circulated back to the gasifier, and the remaining residual solids are discharged from t...

Embodiment 2

[0043] The carbonaceous material used in this example is lignite, and its main properties are listed in Table 1. Mix iron oxide and potassium sulfate with deionized water at a mass ratio of 1:1 to form a slurry as a gasification catalyst. Mix lignite with iron oxide + potassium sulfate slurry at a mass ratio of 95:5, stir evenly, dehydrate and dry at 300°C for 30 minutes, then pulverize and grind to obtain a particle size range of 10-200 mesh (0.075-2.00mm). The above-mentioned solid particles are divided into two streams according to a certain ratio, and the mixed gas composed of oxygen + water vapor containing different oxygen content is sent into the gasifier through the feed port located on the side wall and bottom of the fluidized bed gasifier. Inside, the gasification reaction takes place. At the top of the gasifier, the reaction residual solids and gaseous products are separated by cyclone technology. Part of the residual solids are mixed with the pulverized and groun...

Embodiment 3

[0045] The carbonaceous material used in this embodiment is a heavy oil cracking spent agent, the heavy oil cracking spent agent with a particle size range of 80-325 mesh (0.047-0.18mm) and a carbon mass fraction of 2.85% is divided into The two streams are sent into the gasifier together with the mixed gas composed of oxygen + water vapor containing different oxygen content through the feed port located on the side wall and bottom of the fluidized bed gasifier, and the gasification reaction occurs. At the top of the gasifier, the reaction residual solids and gaseous products are separated by cyclone technology. A part of the residual solid is mixed with the initial spent agent, and is circulated back to the gasifier, and the remaining residual solid is discharged from the system after exchanging heat with the gasifying agent. The main operating conditions and distribution of gasification products are listed in Table 2. As shown in Table 2, the integral fraction of synthesis g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com