Catalyst facilitating direct preparation of light olefins from syngas as well as preparation and application of catalyst

A low-carbon olefin and catalyst technology, applied in the field of iron-based catalysts, can solve the problems of complex catalyst composition, complex preparation process, low CO conversion rate, etc., and achieve the effects of reducing selectivity, simple preparation method, and avoiding secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

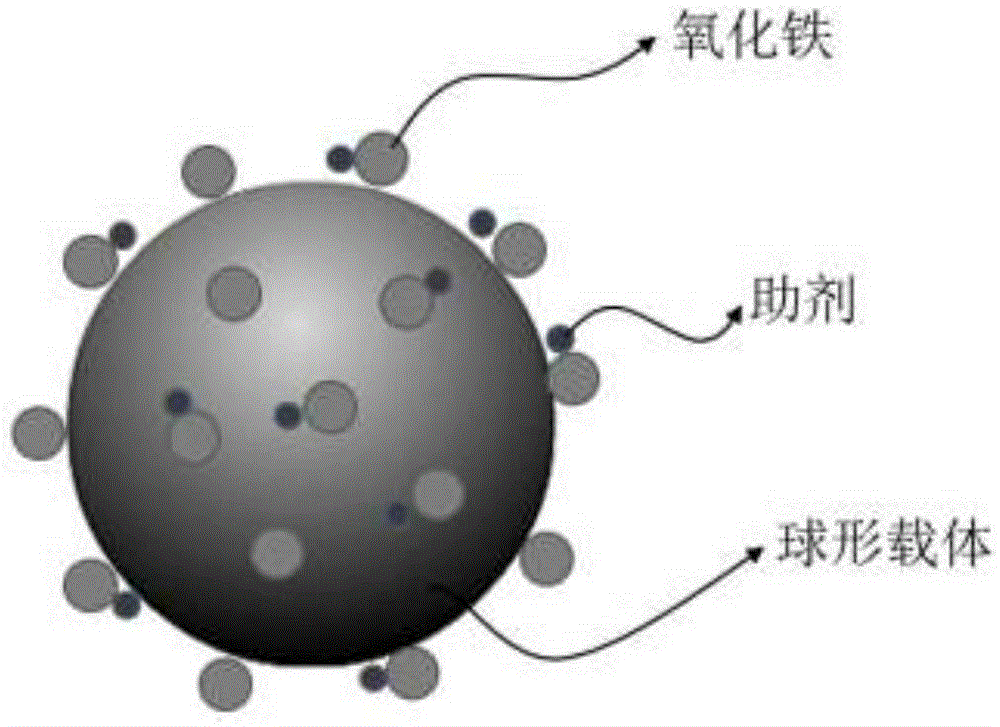

Image

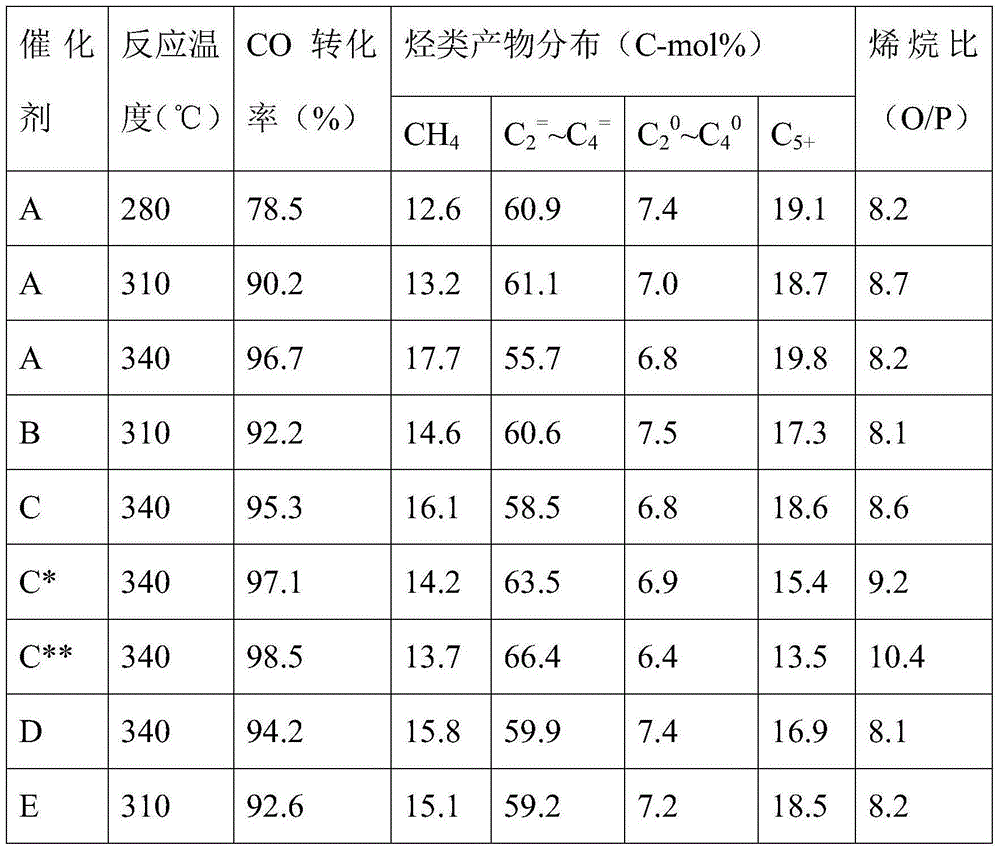

Examples

Embodiment 1

[0029] Take 1.523g of silicon carbide dried at 120°C for 10h, add 25mL of ferric nitrate solution containing 0.689g into the silicon carbide, stir continuously at room temperature for 10h, and then evaporate to dryness under negative pressure at 90°C, and dry at 120°C 12h, and then roasted in a muffle furnace at 350°C for 5h to obtain Fe 2 o 3 Catalyst A at 13% by weight.

Embodiment 2

[0031]Take 8.245g of manganese dioxide dried at 120°C for 10h, add 100mL of a solution containing 6.256g of ferric nitrate and 1.198g of ammonium molybdate into the manganese dioxide, stir continuously at room temperature for 10h, and then rotary evaporate at 90°C under negative pressure to Dry and dry at 120°C for 12h, and then bake in a muffle furnace at 450°C for 5h to obtain Fe 2 o 3 Content is 18.22wt%, MoO 3 Catalyst B at 9.01% by weight.

Embodiment 3

[0033] Take 4.526g of titanium dioxide dried at 120°C for 10h, add 50mL of a solution containing 4.256g of ferric nitrate and 0.322g of potassium nitrate into the titanium dioxide, stir continuously at room temperature for 10h, then evaporate to dryness under negative pressure at 90°C and dry at 120°C Drying for 12 hours under the hood, and finally roasting in a muffle furnace at 450°C for 5 hours to obtain Fe 2 o 3 The content is 23.1wt%, K 2 Catalyst C with an O content of 5.3 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com