Method and system for cracking waste rubber

A technology of waste rubber and cracking system, which is applied in the field of composite cracking combining heat transfer cracking and microwave cracking, can solve the problems of poor carbon black product quality, high production cost and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

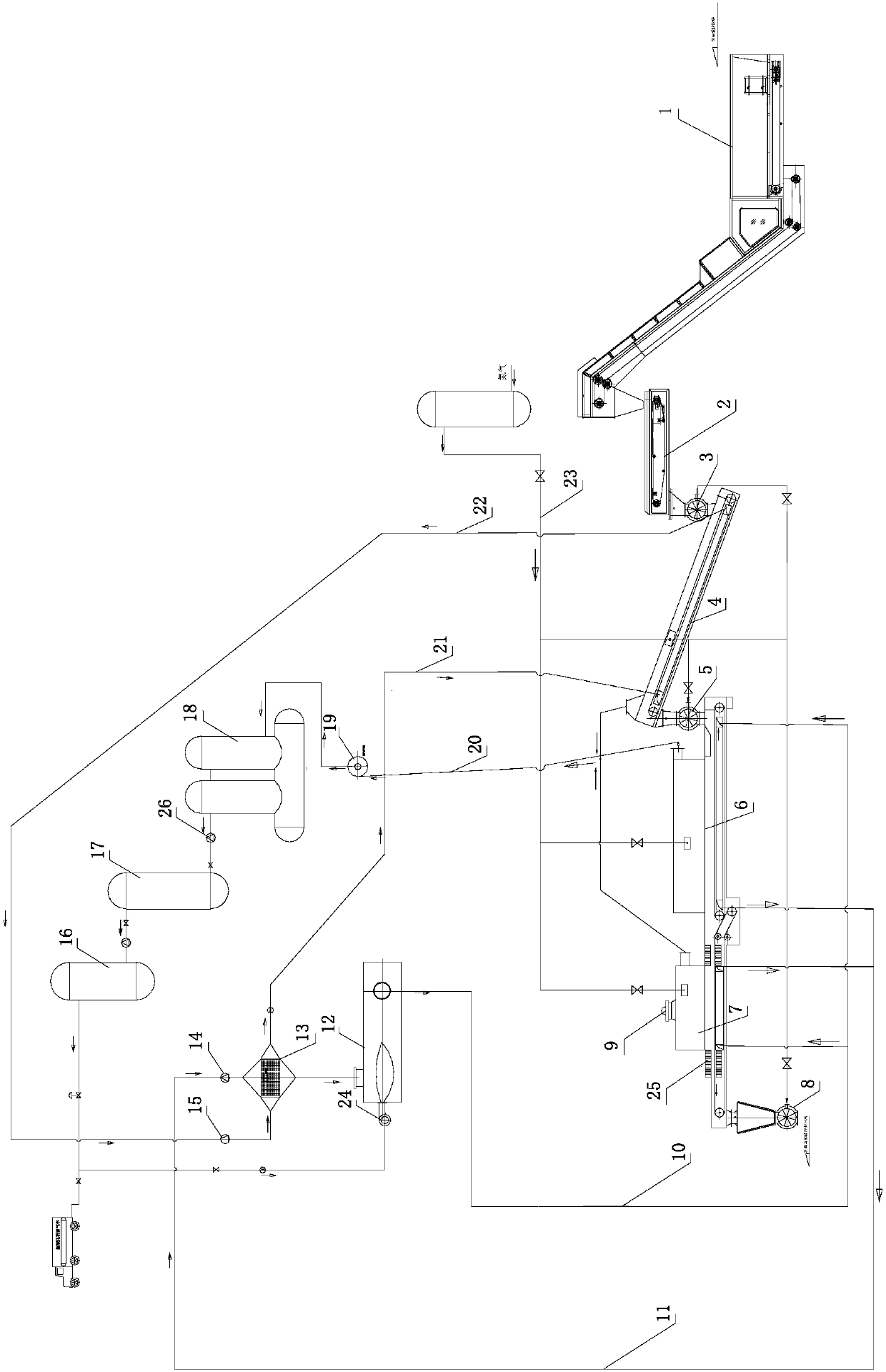

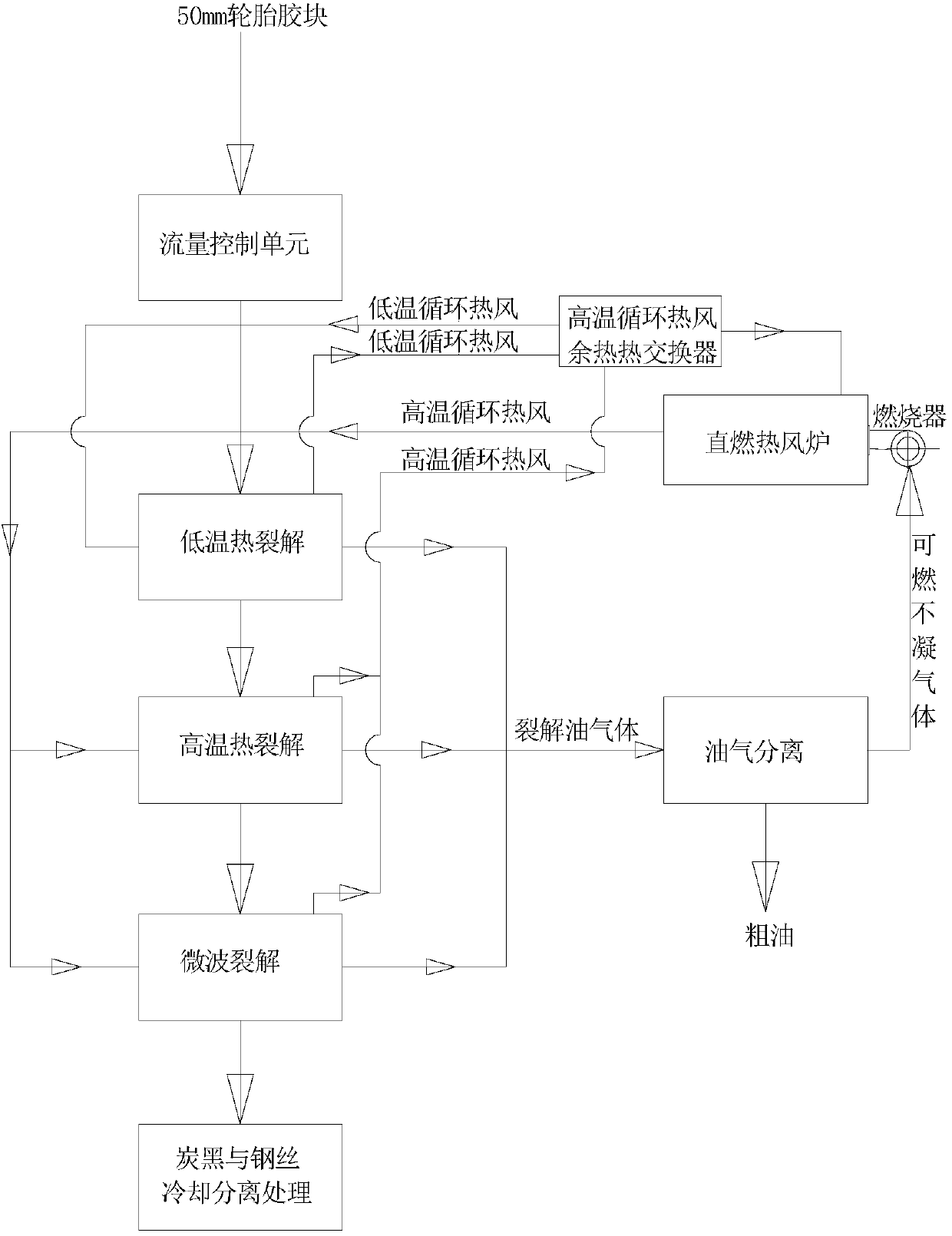

[0049] Such as figure 1 As shown, the cracking system of the present invention includes a feeding device, an oil and gas collection device, an oxygen removal device, a heating device, and a low-temperature thermal cracking chamber 4, a high-temperature thermal cracking chamber 6, a microwave cracking chamber 7, and a microwave cracking chamber that are sequentially sealed and connected. 7 is provided with a microwave source 9, and the inlet and outlet ends of the microwave cracking chamber 7 are also provided with a suppressor 25 to prevent microwave leakage; the low-temperature thermal cracking chamber 4, the high-temperature thermal cracking chamber 6, and the microwave cracking chamber 7 are all provided with stainless steel mesh belt conveyor. The discharge end of the low-temperature thermal cracking chamber 4 is higher than the feed end of the high-temperature thermal cracking chamber 6, and is connected through a nitrogen-sealed rotary valve B5. The high-temperature the...

Embodiment 2

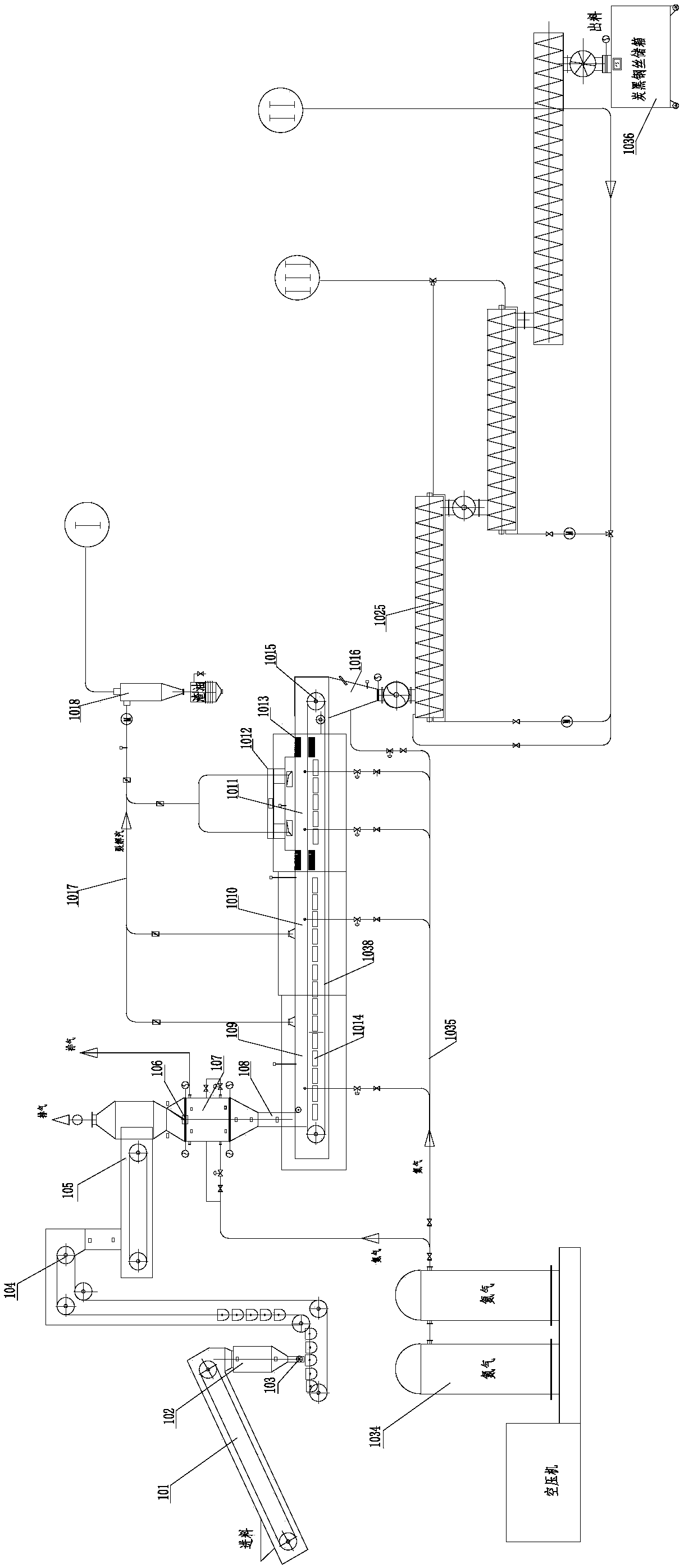

[0061] Such as image 3 , 4 As shown, the cracking system of the present invention includes a feeding device, an oil and gas collecting device, an oxygen removal device, a heating device, and a low-temperature thermal cracking chamber 109 connected in series, a high-temperature thermal cracking chamber 1010, a microwave cracking chamber 1011, and a microwave cracking chamber 1011 is provided with a microwave source 1012, and the inlet and outlet ends of the microwave cracking chamber 1011 are also provided with a suppressor 1013 to prevent microwave leakage; the low-temperature thermal cracking chamber 109, the high-temperature thermal cracking chamber 1010, and the microwave cracking chamber 1011 share a stainless steel mesh belt for conveying Machine 1038.

[0062] The feeding device includes a belt conveyor 101, a storage bin 102, a feeding roller 103, a hoist 104, a belt scale 105, a material guide plate 106, an alternate deoxygenation bin 107, and a feeding pipe 108. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com