Patents

Literature

32results about How to "Limit content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

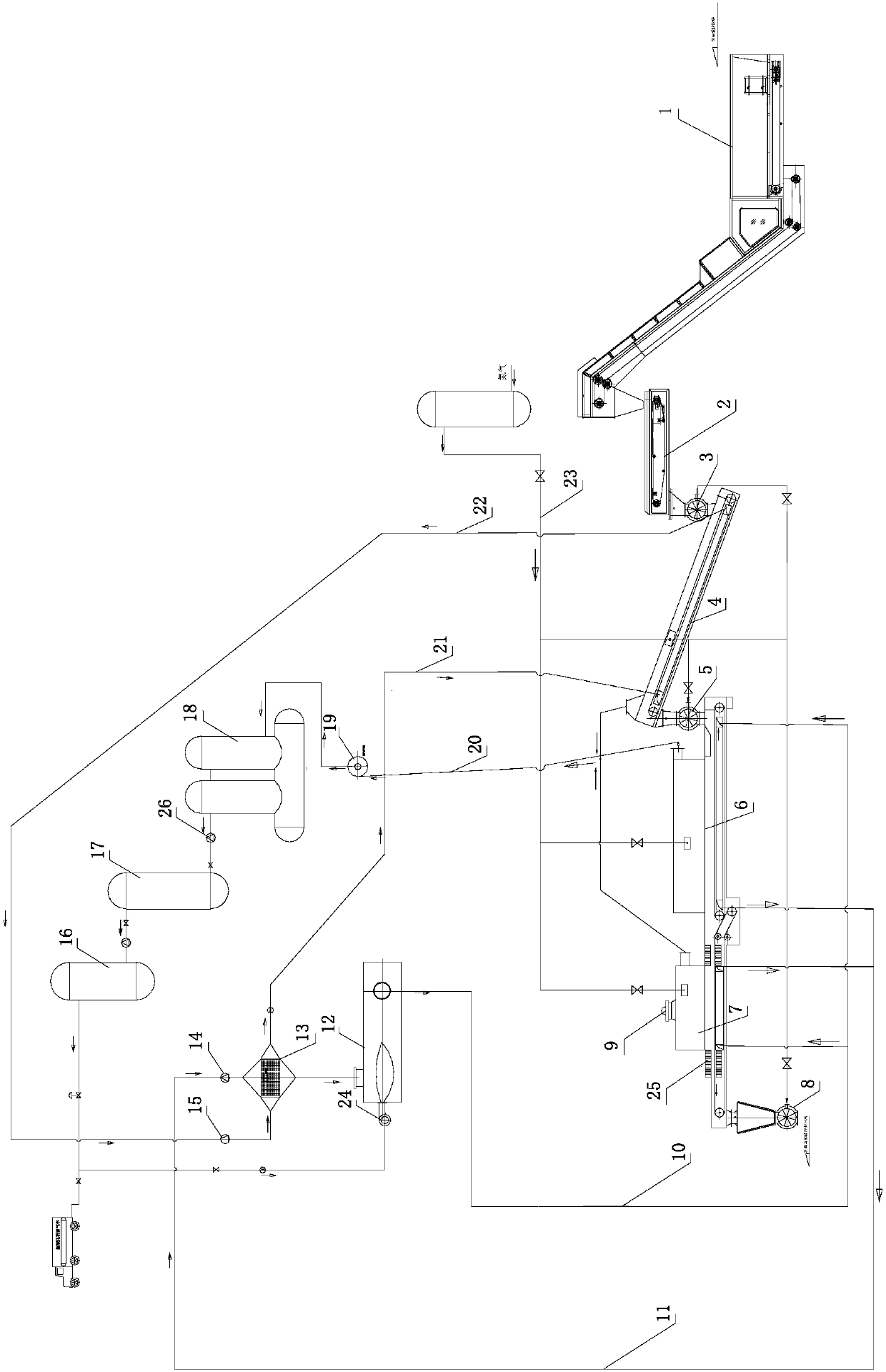

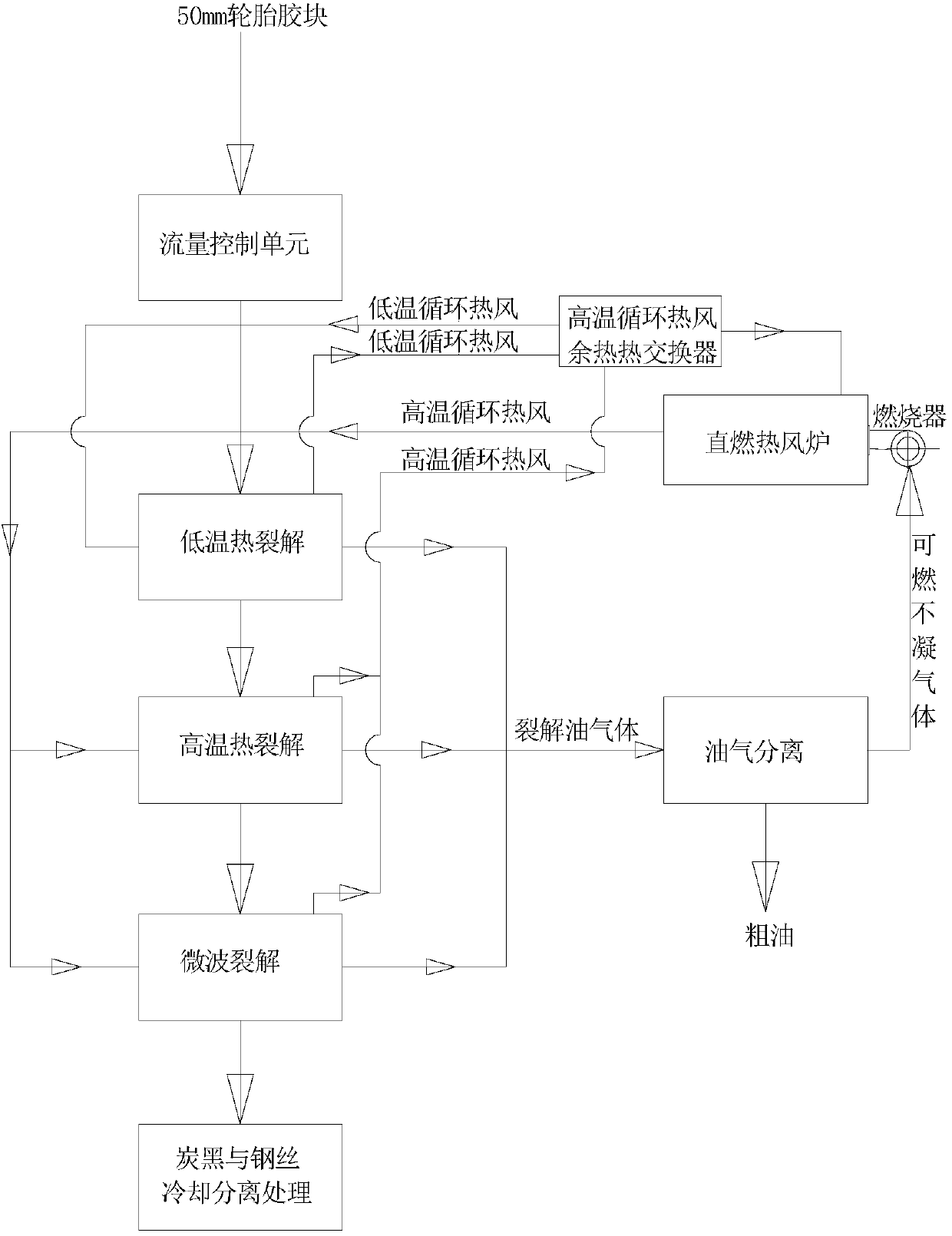

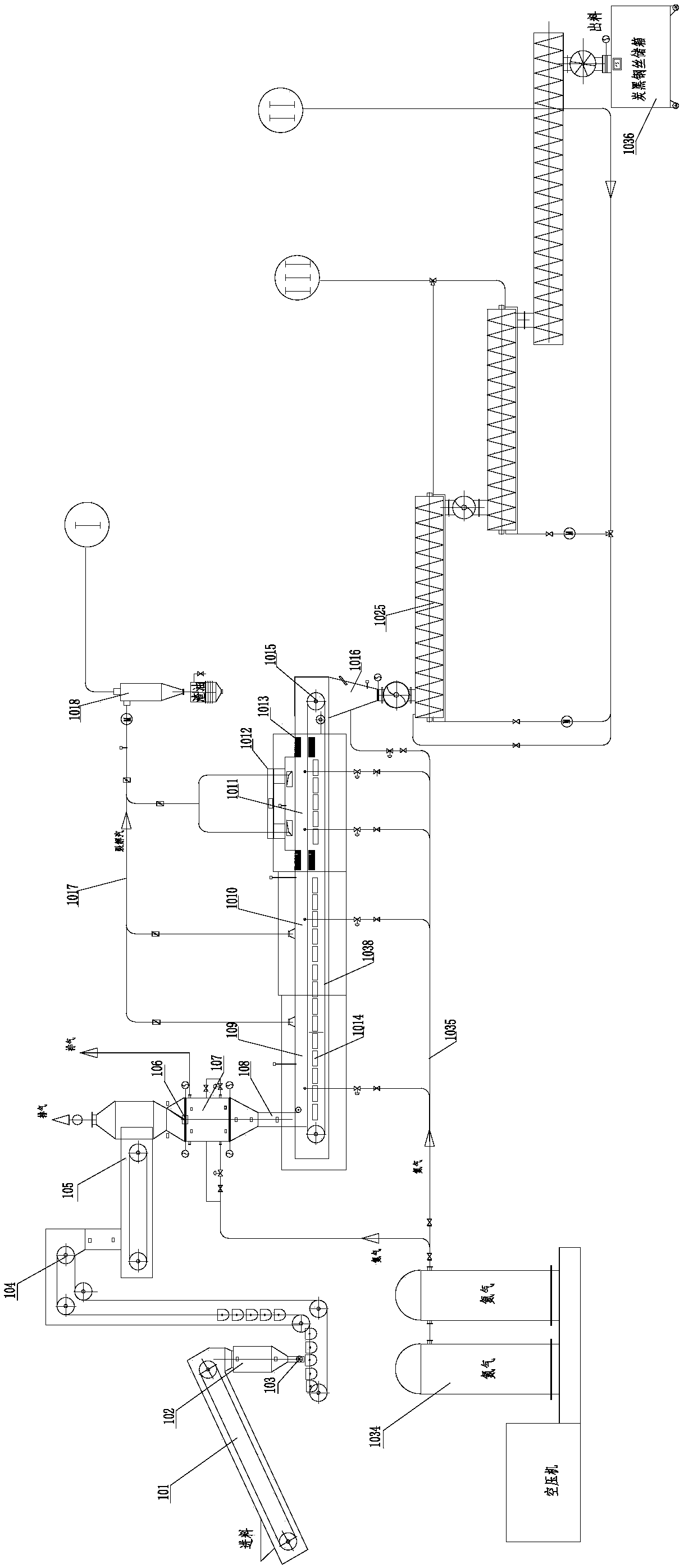

Method and system for cracking waste rubber

PendingCN108018062ARapid lysisReduce energy consumptionPigmenting treatmentTransportation and packagingMicrowaveWaste rubber

The invention provides a method and a system for cracking waste rubber. The waste rubber is sequentially sent to a low-temperature thermal cracking chamber, a high-temperature thermal cracking chamberand a microwave cracking chamber which respectively have an oxygen-free or oxygen-deficient environment, wherein thermal cracking of the waste rubber in the low-temperature thermal cracking chamber is carried out in a 200-400 DEG C environment, thermal cracking in the high-temperature thermal cracking chamber is carried out in a 500-800 DEG C environment, and microwave cracking in the microwave cracking chamber is carried out in a 500-800 DEG C environment; a cracking oil gas generated in the cracking process is continuously discharged from the low-temperature thermal cracking chamber, the high-temperature thermal cracking chamber and the microwave cracking chamber; and solids generated in the cracking process are recovered. The method and the system can effectively reduce the energy consumption in the cracking process and improve the cracking efficiency of the waste tire and the quality of cracked carbon black.

Owner:江苏林达智思环保科技有限公司

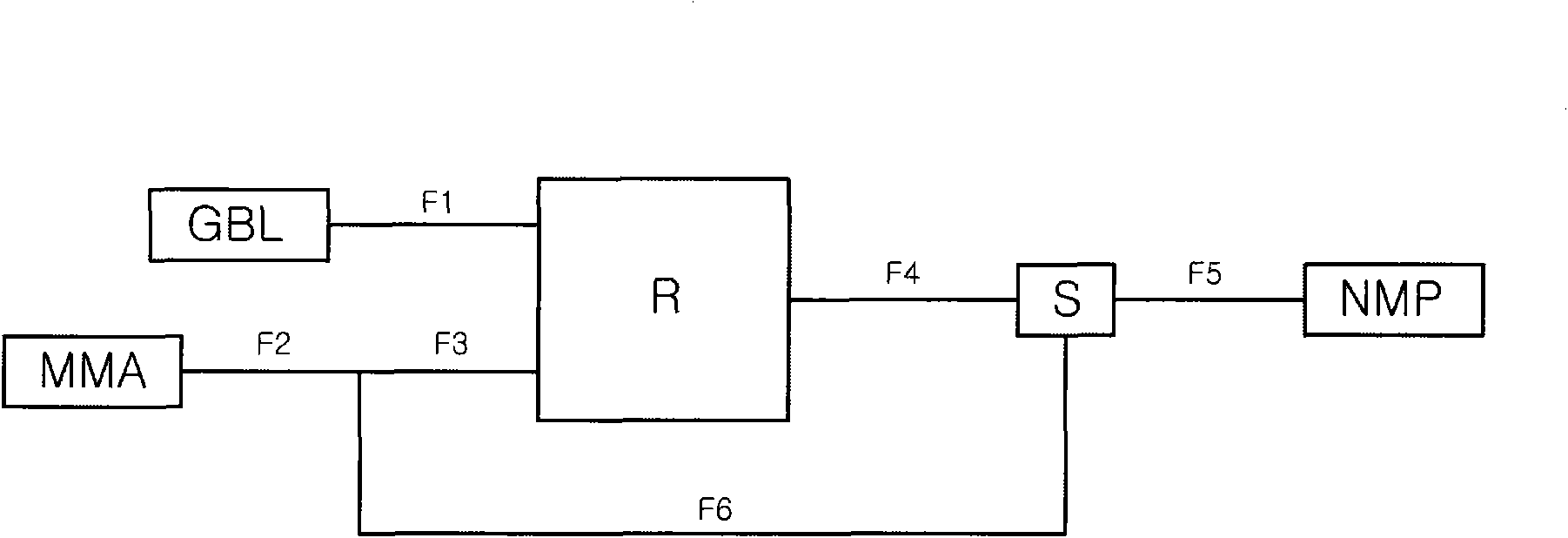

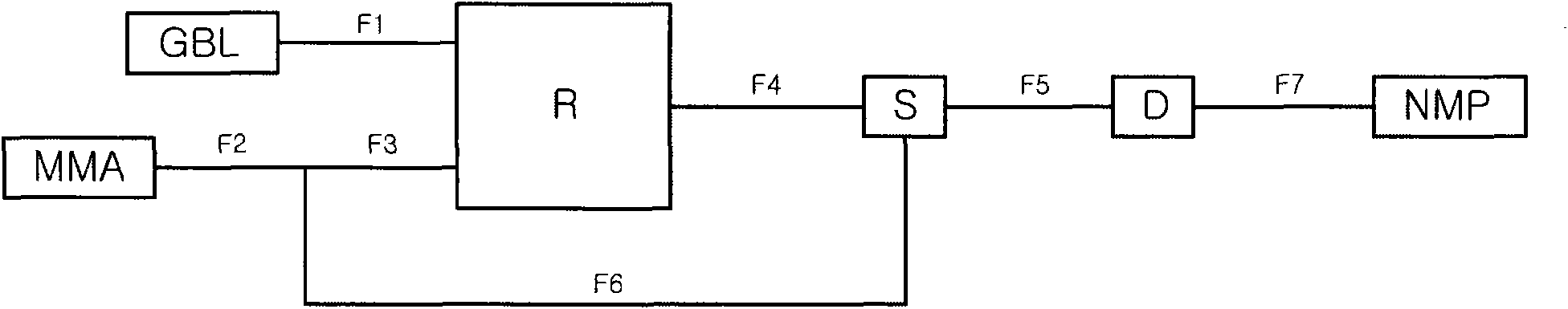

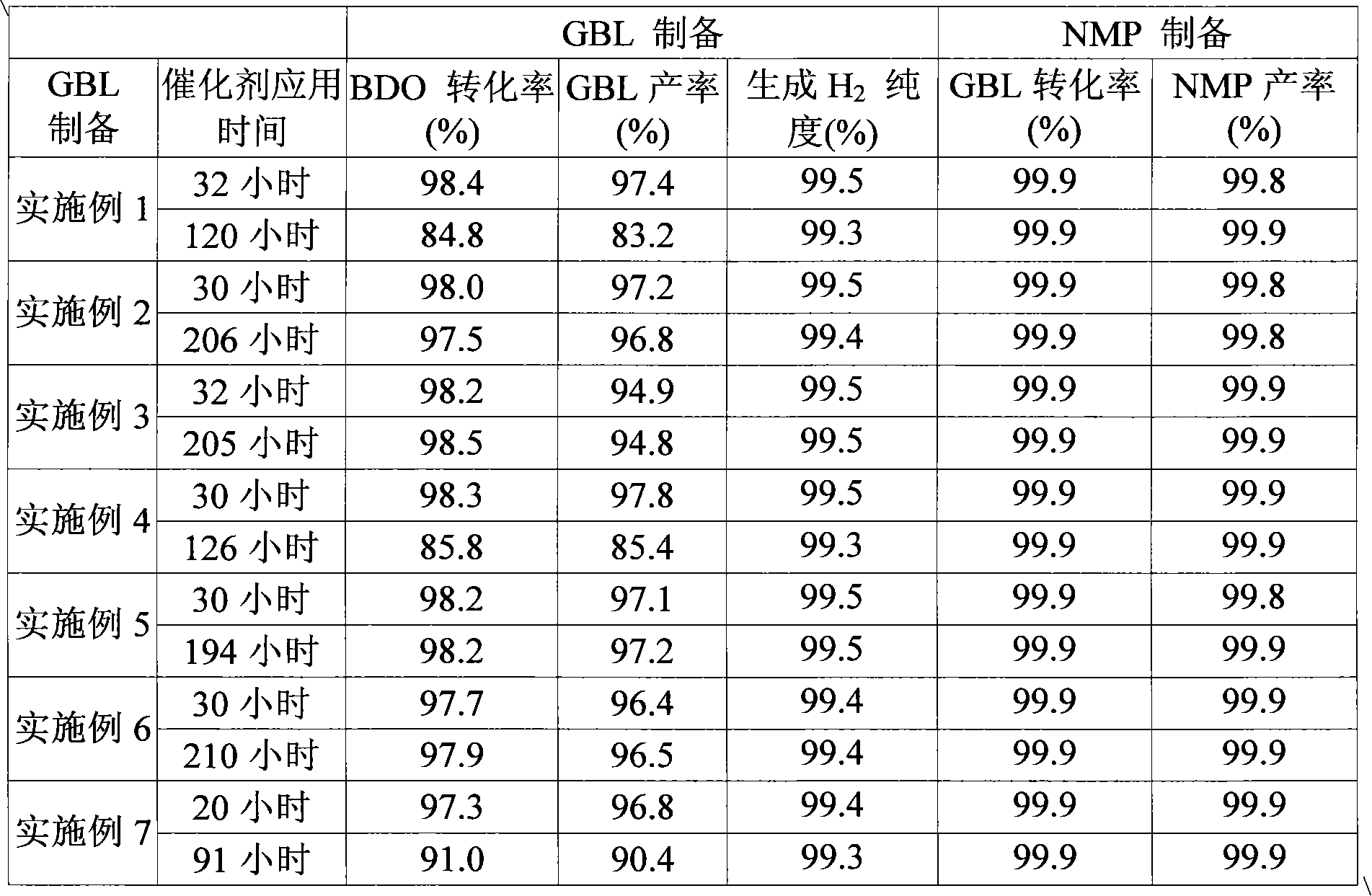

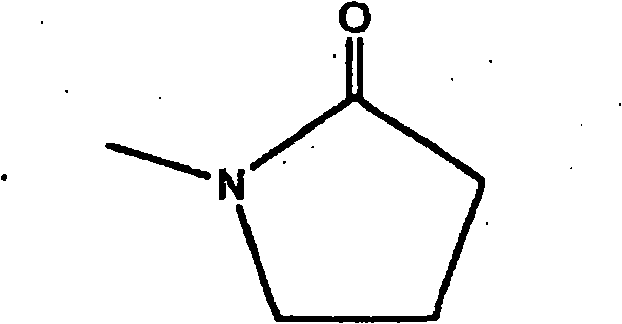

Method for preparing n-methylpyrrolidone from 1,4-butanediol

InactiveCN102070501AAvoid pollutionLimit contentOrganic chemistryMetal/metal-oxides/metal-hydroxide catalysts1,4-ButanediolDehydrogenation

The invention provides a method for preparing gamma-butyrolactone (GBL) and N-methylpyrrolidone (NMP), more specifically, a method for preparing NMP, comprising introducing 1,4-butanediol in a reactor, performing dehydrogenation in the presence of metallic oxide catalyst to provide GBL; supplying monomethyl amine (MMA) aqueous solution and GBL to the reactor; separating the NMP generated by the reaction of the MMA and the GBL from the water; mixing the separated water with the MMA to provide the MMA aqueous solution; and leading the MMA aqueous solution back into the reactor. Since the GBL is prepared from the butanediol in the presence of the catalyst, the water generated from the reaction of the MMA and the GBL is collected to provide the MMA aqueous solution, and the MMA aqueous solution is returned to the reactor, the prepared NMP has the advantages that energy is saved and simple separation of the product NMP is realized.

Owner:SK INNOVATION CO LTD +1

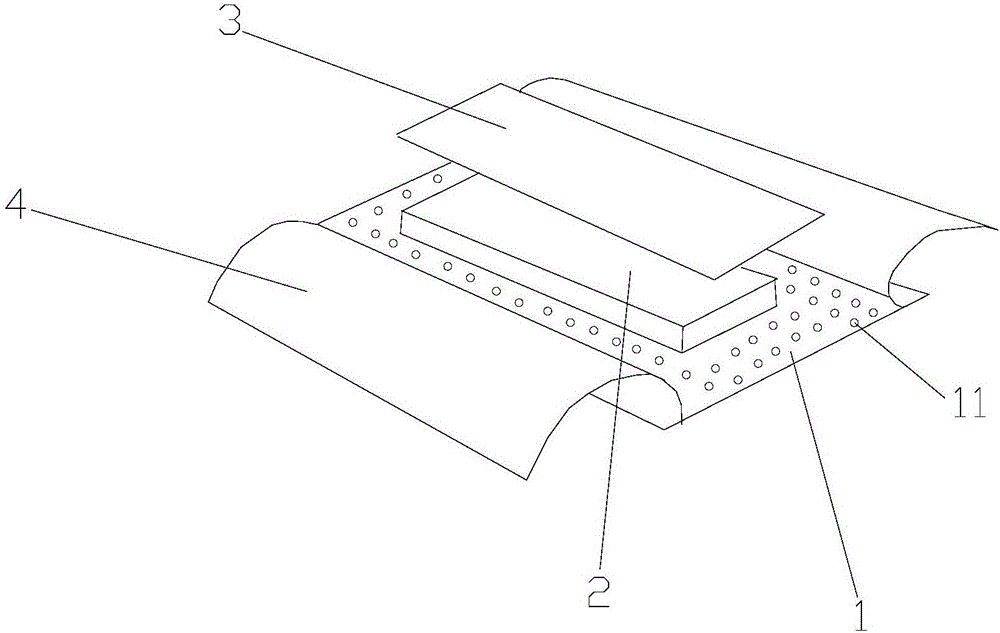

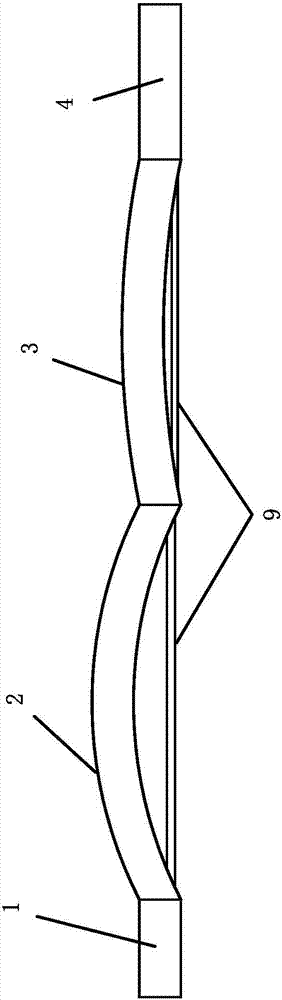

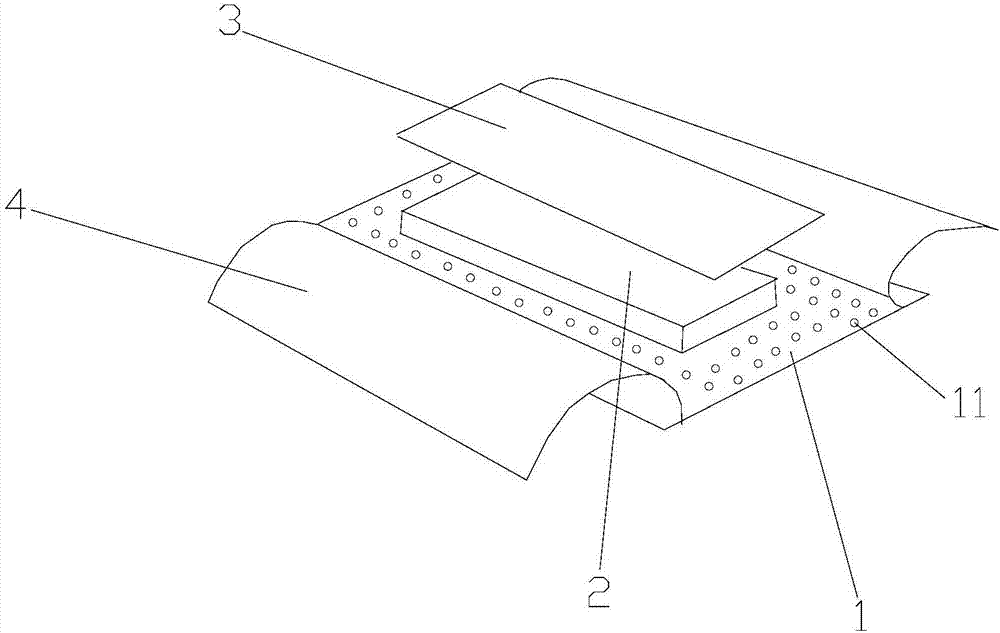

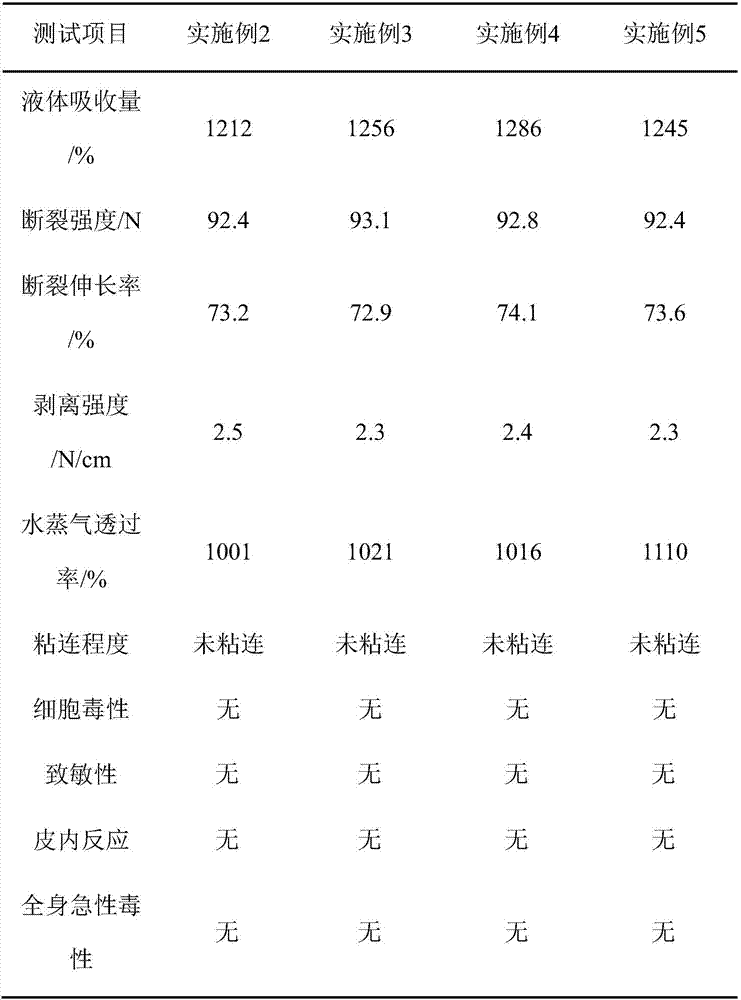

Anti-sticking alginate dressing and preparation method thereof

ActiveCN106176045ANot easy to get inSuitable humidityAdhesive dressingsAbsorbent padsSurface layerBiomedical engineering

The invention discloses anti-sticking alginate dressing and a preparation method thereof. The alginate dressing comprises a bottom layer, a water-absorbing layer, a surface layer and an anti-sticking layer, wherein the alginate dressing is of a layered structure; the bottom layer, the water-absorbing layer, the surface layer and the anti-sticking layer are sequentially overlapped to form the layered structure; breathable holes are formed in the bottom layer; the hole diameters of the breathable holes are smaller than or equal to 0.22 micron. The breathable holes are formed in the bottom layer of the dressing, and the hole diameters of the breathable holes are smaller than or equal to 0.22 micron, so that the dressing has a breathable function, and bacteria are unlikely to enter; the alginate dressing provided by the invention is further provided with the water-absorbing layer, and the provided water-absorbing layer can maintain proper humidity of a wound, so that wound healing is facilitated.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

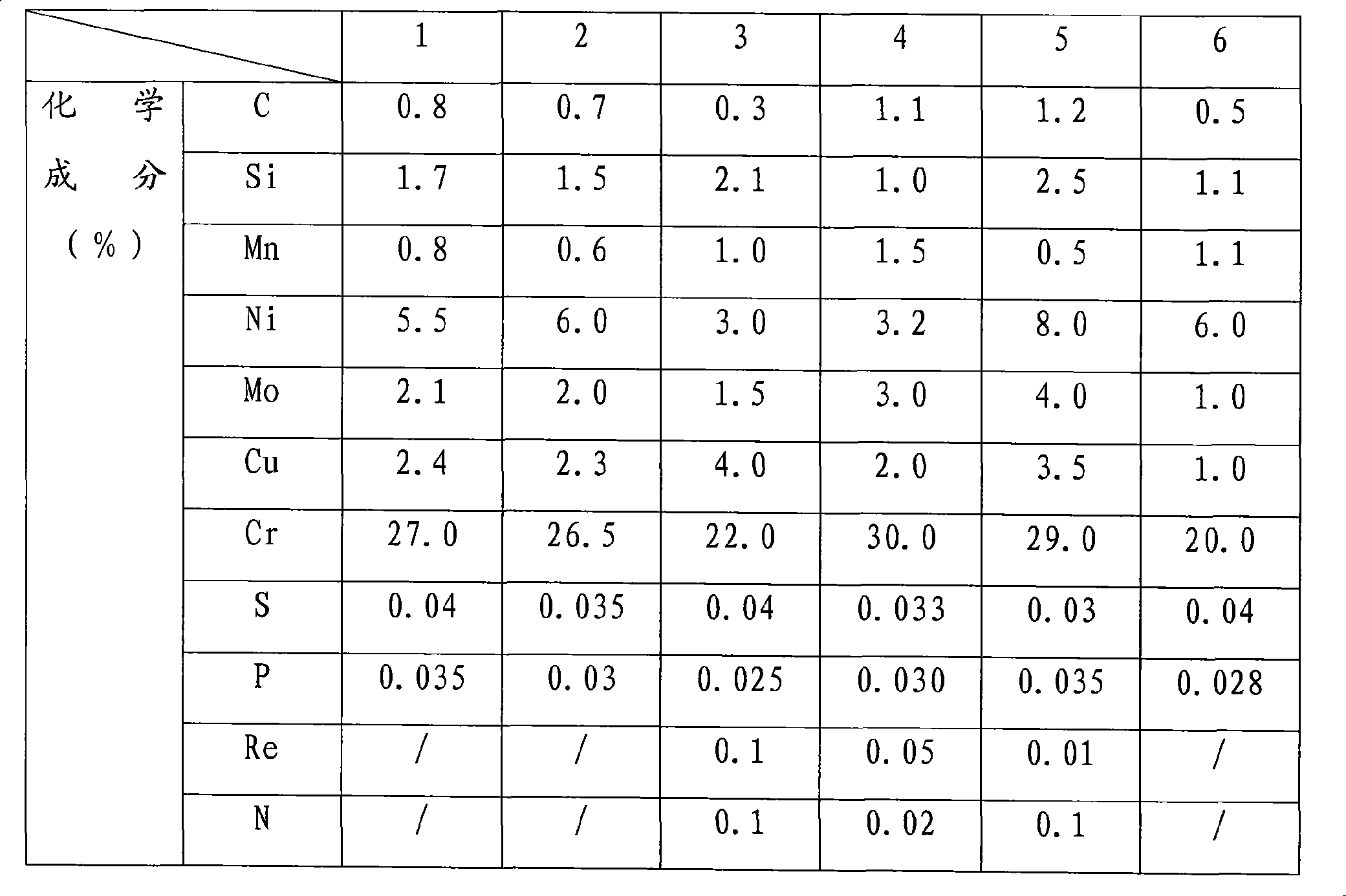

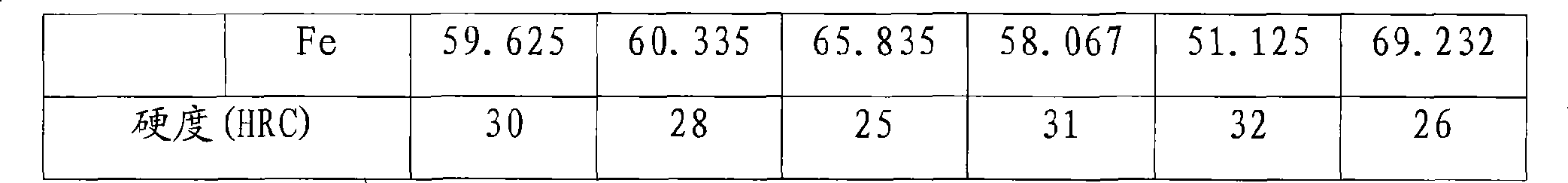

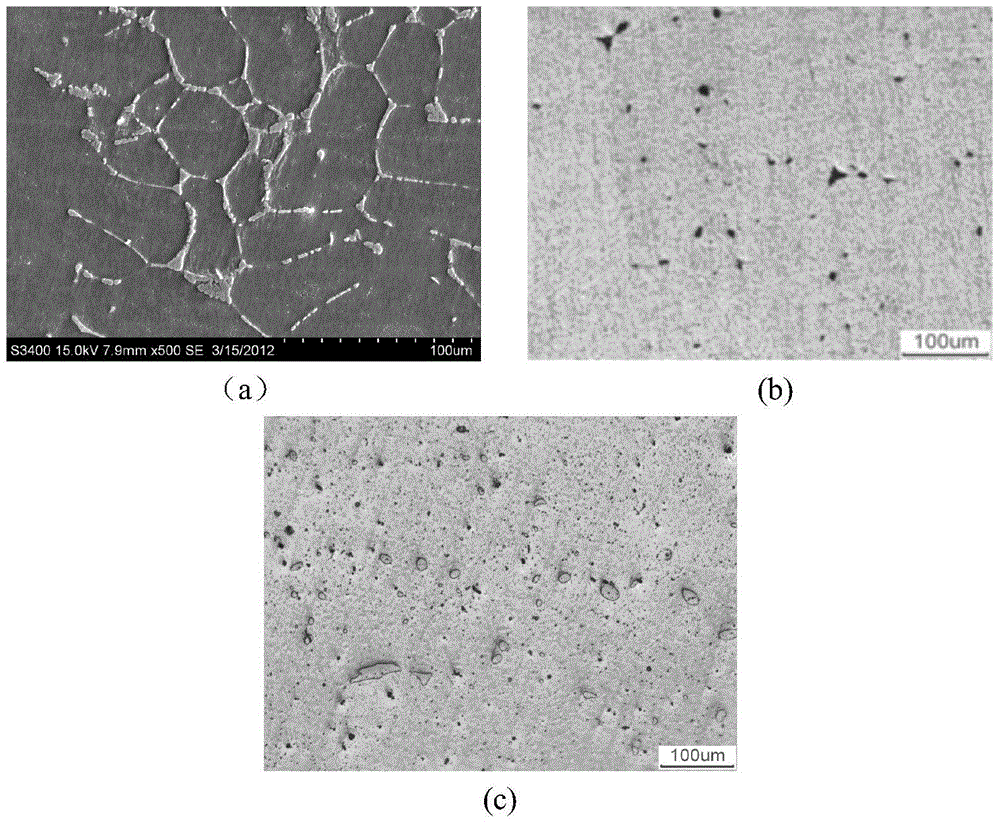

Novel corrosion resistant antiwear metallic material

The invention discloses a novel corrosion-resistant anti-wear metallic material which has the components with the weight percentage of 0.3-1.2% of C, 20-30% of Cr, 1-2.5% of Si, 0.5-1.5% of Mn, 3-8% of Ni, 1-4% of Mo, 1-4% of Cu, less than or equal to 0.035% of P, less than or equal to 0.04% of S, and the rest of Fe. As the novel corrosion-resistant anti-wear metallic material properly increases the carbon content and is added with the right amount of alloying elements, so that material structure contains a certain amount of alloy carbide, and the anti-wear performance of the material is greatly improved. Although the static corrosion-resistant performance is slightly reduced, the comprehensive corrosion-resistant anti-wear performance is greatly improved. In addition, the novel corrosion-resistant anti-wear metallic material can be smelted in an intermediate frequency furnace and needs no concentrated feeding stuff. The production cost is reduced more than CD4M-Cu material.

Owner:SHIJIAZHUANG IND PUMP FACTORY CO LTD

Solid powder multi-element composite infiltration agent and composite infiltration process

ActiveCN109468581AFast penetrationFine grainSolid state diffusion coatingRare earthOxidation resistant

The invention relates to a solid powder multi-element composite infiltration agent and a composite infiltration process, and belongs to the technical field of metal surface treatment. The composite infiltration agent is composed of a chromium source, a vanadium source, a boron source, nickel powder, an activating agent, a filling agent, an oxygen scavenger and a rare-earth infiltration enhancer. The composite infiltration agent has the effects of rapid infiltration speed, no pollution, improving the structural density of an infiltration layer, and avoiding the embrittlement of the infiltrationlayer. The composite infiltration process comprises the following steps of carrying out acid pickling activation pretreatment on a base body material, then burying the base body material into the composite infiltration agent, heating and preserving heat in a carbon-containing or nitrogen-containing atmosphere, and then carrying out quenching treatment after furnace cooling. According to the process, the method is simple, no pollution occurs, the infiltration speed is rapid, the infiltration agent is free of hardening, and the surface of an infiltrated workpiece is clean. The prepared composite infiltration layer is fine in the crystalline grains and compact in the structure, has a good gradient structure, has the toughness, the wear resistance, the corrosion resistance, the high-temperature oxidation resistance and the like, and can be applied to parts such as a tool, a mold, a bearing, and a gear.

Owner:GUANGDONG INST OF NEW MATERIALS

Method for producing silicate clinker by replacing silicon-aluminum raw material ingredients with modified coal gangue

InactiveCN111704375ASolve the pollution problemReduce consumptionCement productionClinker (cement)Materials science

The invention discloses a method for producing silicate clinker by replacing silicon-aluminum raw material ingredients with modified coal gangue. The method comprises the following steps of: (1) modifying coal gangue; (2) preparing raw material powder from the modified coal gangue instead of a silicon-aluminum raw material, and carrying out pre-decomposition; and (3) adjusting the use amount of tailings, oxidizing and calcining. According to the invention, the problem that the working condition stability of the kiln system is influenced by serious crusting and sticking of the kiln system due to the characteristics of the raw coal gangue can be solved, so that large-scale consumption of the coal gangue by cement enterprises is facilitated, and the problem of environmental pollution caused by coal gangue accumulation is solved.

Owner:长沙紫宸科技开发有限公司

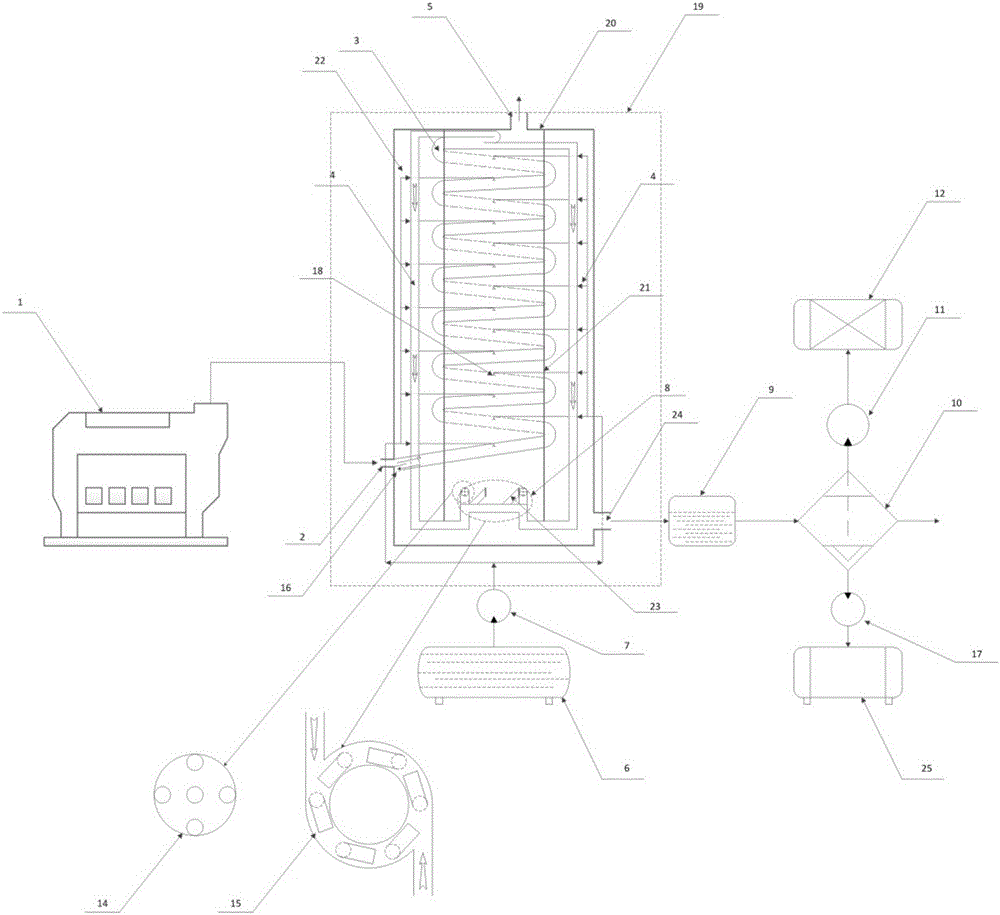

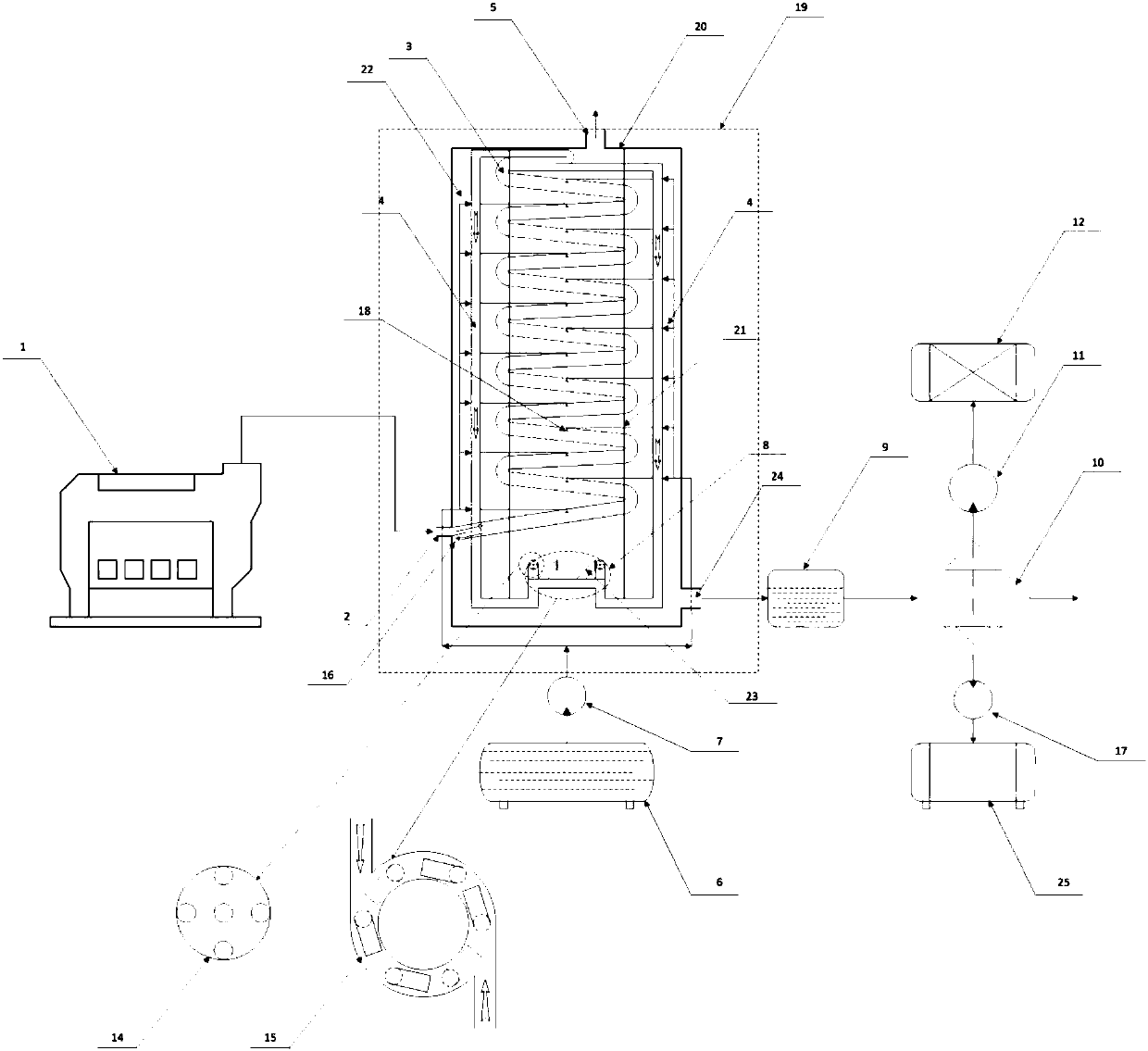

Marine exhaust gas SOx removal device for rotary spraying refluxing bubble tower

ActiveCN105749710AAdd processing pathReduce rateGas treatmentDispersed particle separationLiquid wasteAtmospheric air

The invention aims to provide a marine exhaust gas SOx removal device for a rotary spraying refluxing bubble tower. The marine exhaust gas SOx removal device comprises a washing tower, a NaOH solution storage cabin, a waste liquid buffer tank and waste liquid centrifugal treatment equipment; the washing tower comprises a washing tower outer layer cylinder; a washing tower inner layer cylinder and a spiral rising washing pipeline are arranged in the washing tower outer layer cylinder; an exhaust gas inlet, an exhaust gas outlet and a washing liquid outlet are respectively formed in the outer wall of the washing tower outer layer cylinder; the exhaust gas inlet is connected with a marine diesel engine exhaust pipe; the exhaust gas outlet is communicated with the atmosphere; the washing liquid outlet is communicated with the waste liquid buffer tank; the waste liquid buffer tank is connected with the waste liquid centrifugal treatment equipment; the waste liquid centrifugal treatment equipment is connected with each of an oil contamination storage cabin and a heavy residue storage cabin. According to the marine exhaust gas SOx removal device, SO2 in exhaust gas is subjected to washing treatment by adopting two technologies, namely a novel rotary spraying washing technology and a novel pneumatic stirring bubbling washing technology; the contact path between the washing liquid and the exhaust gas is increased; the acting time is prolonged; the acting area is increased, so that the exhaust gas is treated sufficiently.

Owner:HARBIN ENG UNIV

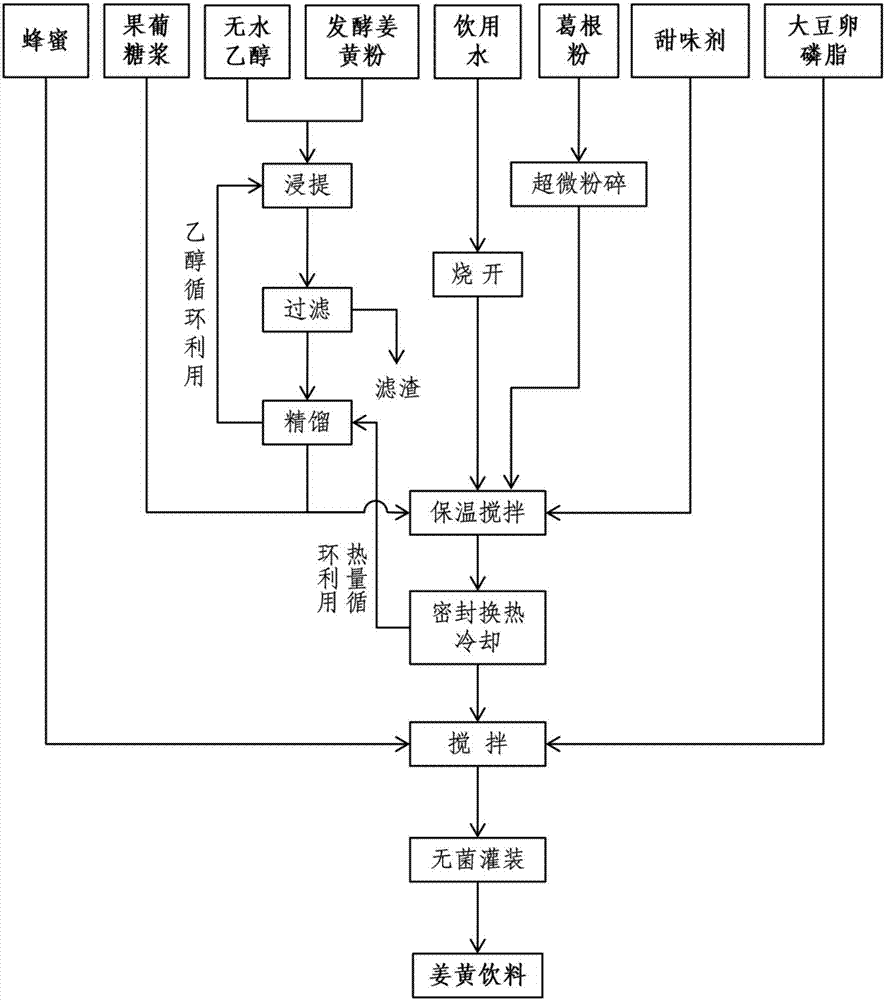

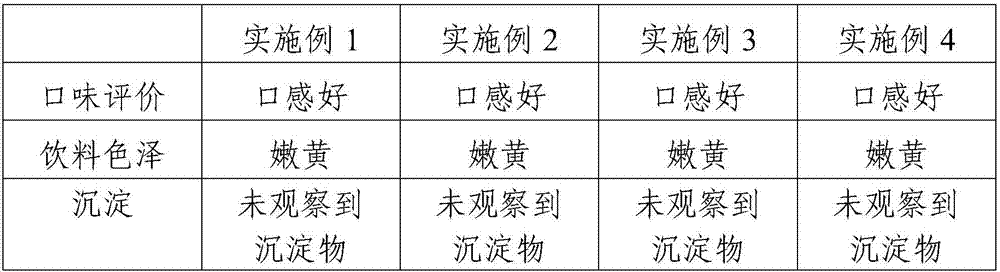

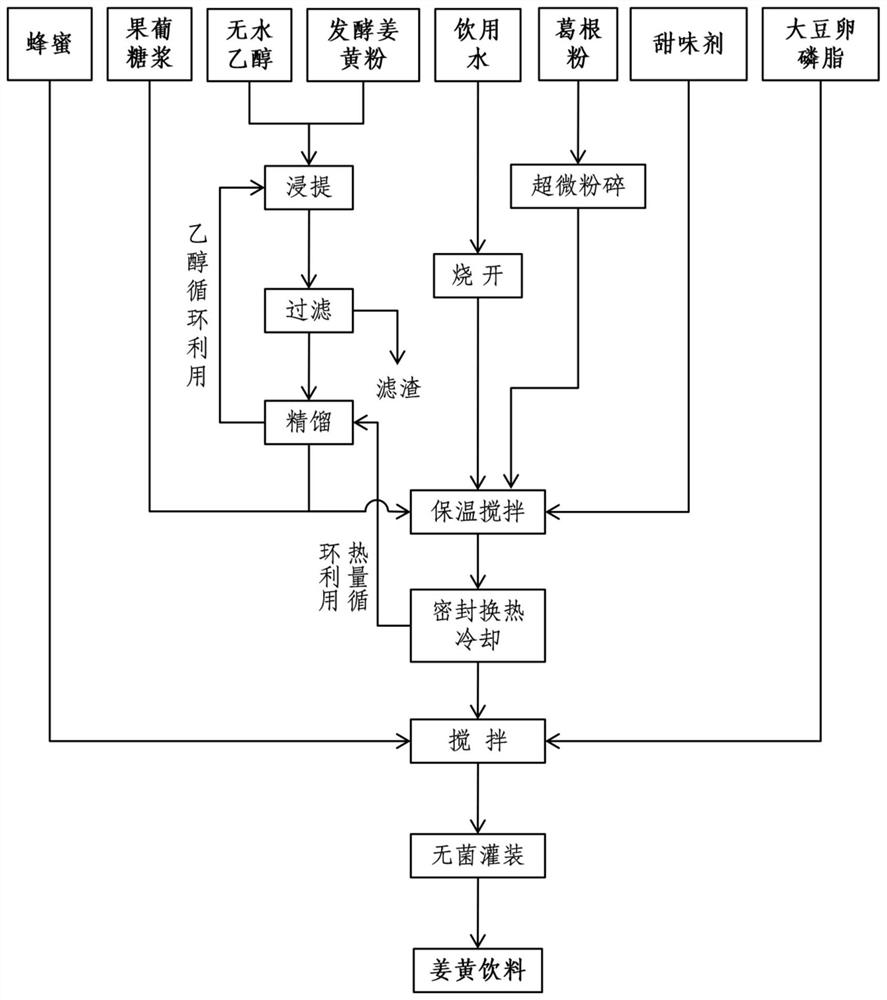

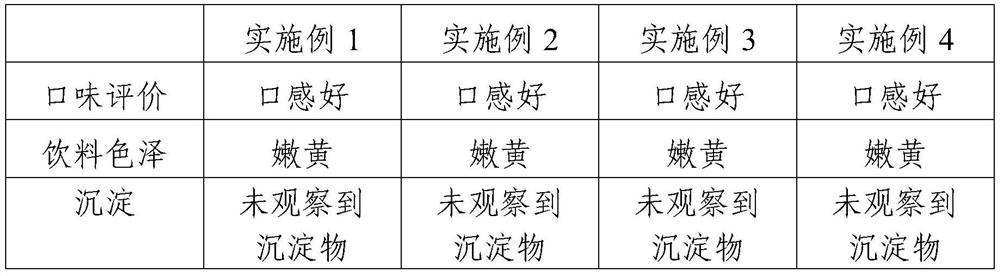

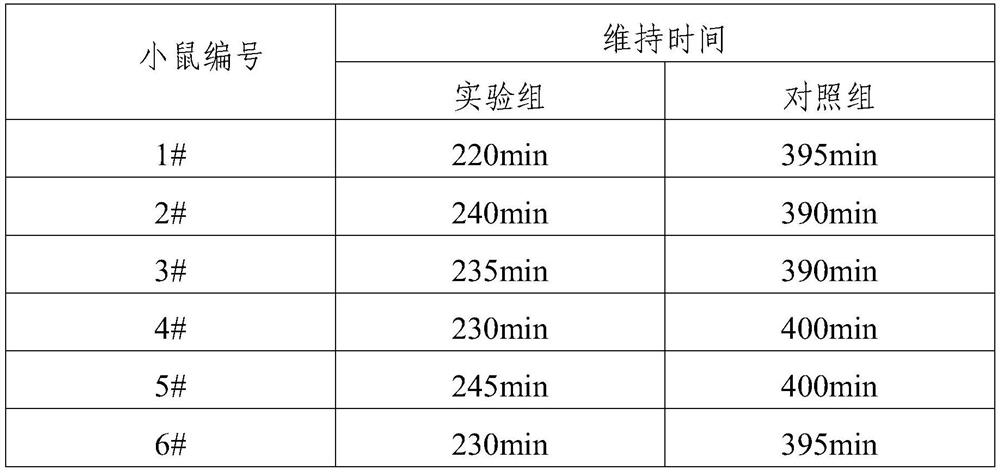

Curcuma beverage and making method thereof

ActiveCN107996932AHigh dissolution rateLow content of harmful impuritiesNatural extract food ingredientsFood ingredient functionsOrganic solventSoybean Lecithin

The invention relates to a curcuma beverage and a making method thereof. The making method comprises the following steps of (1) extracting a curcuma extract from fermented curcuma powder with an organic solvent, so as to obtain an extracting solution containing the curcuma extract; (2) performing rectification on the obtained extracting solution, so as to obtain a curcuma extract; (3) adding the obtained curcuma extract, radix puerariae powder and syrup to boiling water, and performing stirring, so as to obtain a gelatinized mixture; and (4) cooling the gelatinized mixture, and adding honey and soybean lecithin under an aseptic condition, so as to obtain the curcuma beverage. According to the curcuma beverage disclosed by the invention, curcumin is extracted with fermented curcuma powder,so that the extraction rate is increased; the curcuma extract, the radix puerariae powder, the syrup, the honey and the soybean lecithin powder are combined, and through combination of a specific production technology, the problems that the curcumin is low in absorptivity by human bodies, insoluble in water, easy to precipitate and easy to delaminate, are solved; the efficacy of neutralizing the effect of alcoholic drinks, protecting the liver, resisting oxidation and resisting mutation of the curcuma beverage is strengthened; and a new way is developed for the utilization of the curcuma.

Owner:四川新磷环保技术有限公司

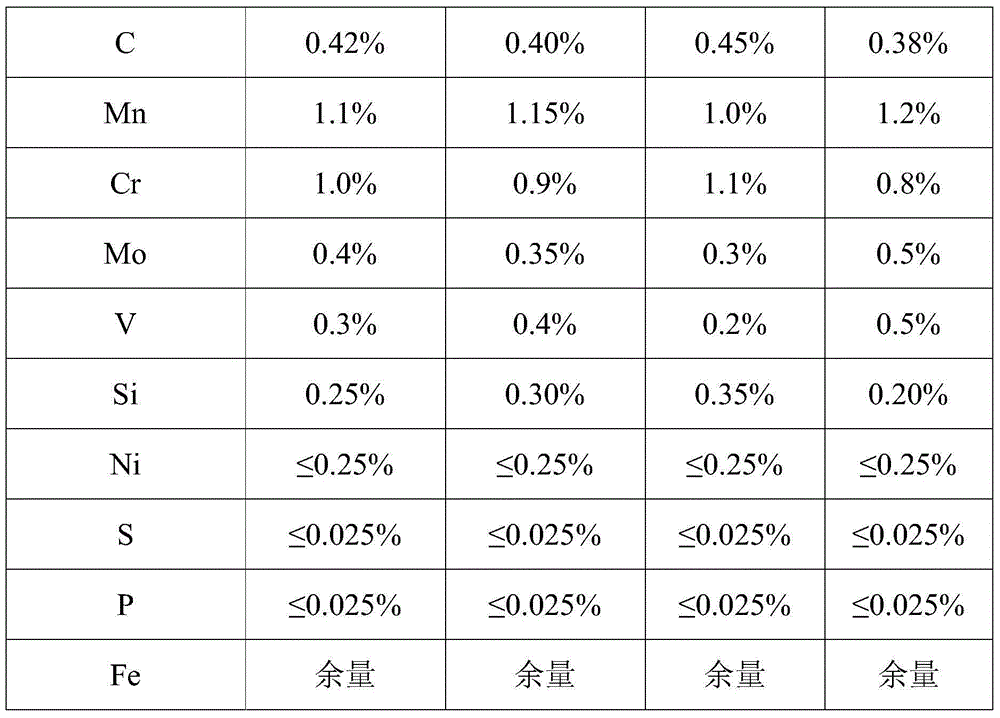

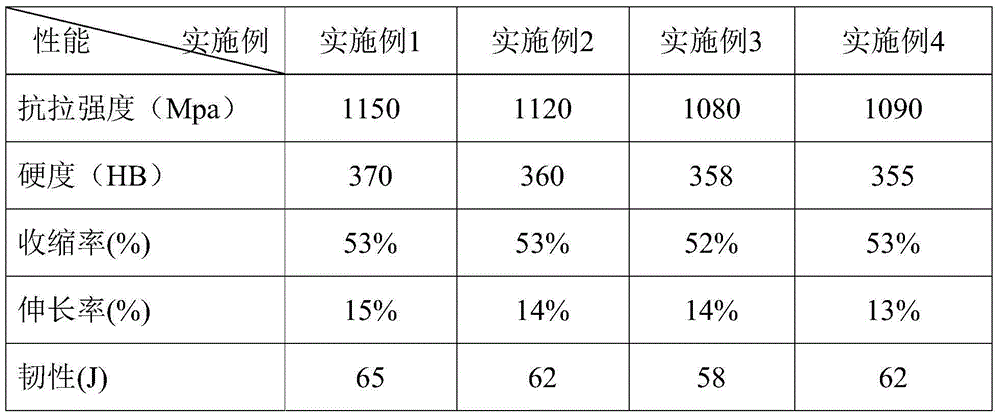

Wear-resisting pin shaft and machining method thereof

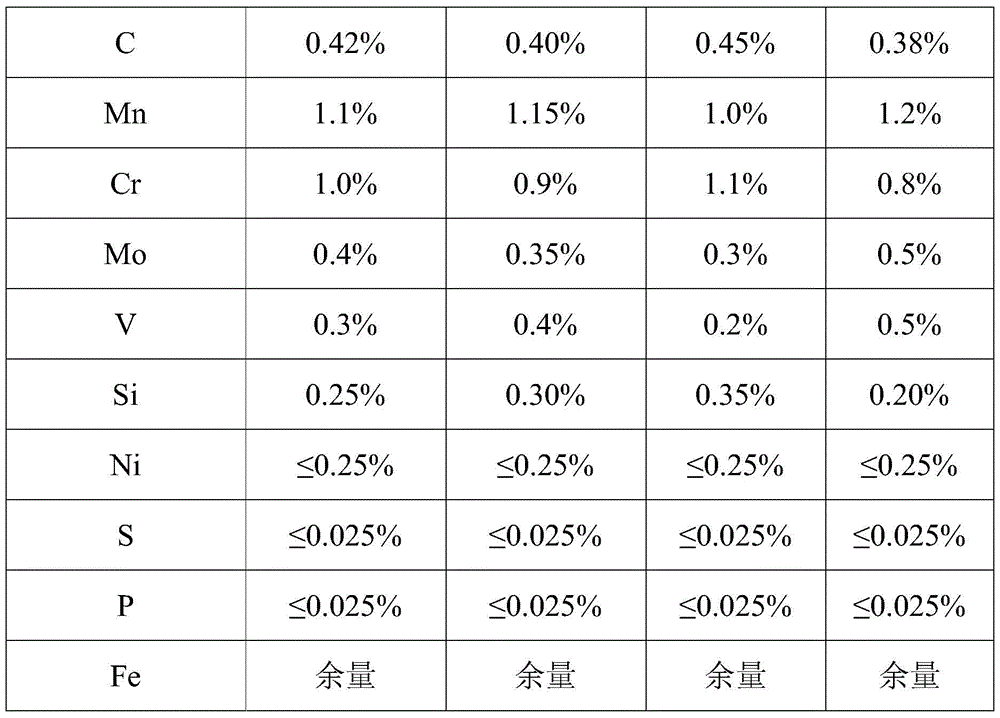

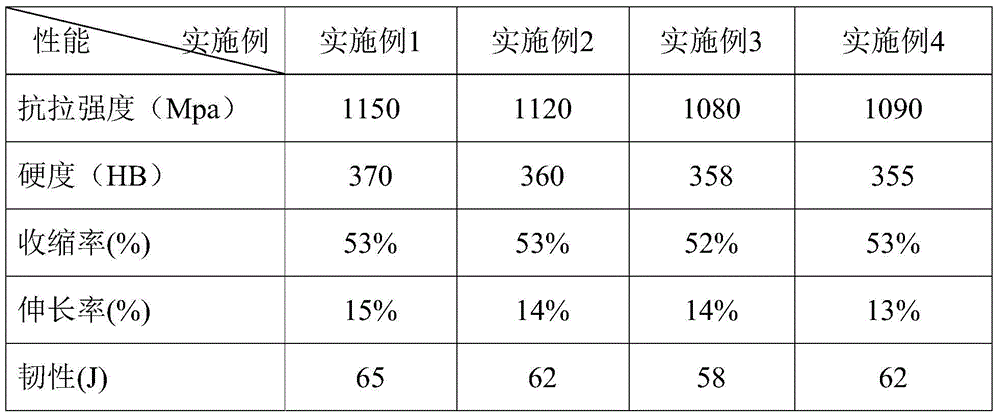

The invention belongs to the technical field of pin shaft machining, and relates to a wear-resisting pin shaft and a machining method thereof. The wear-resisting pin shaft and the machining method thereof solve the problems that an existing pin shaft is low in strength and hardness. The wear-resisting pin shaft is formed by machining wear-resisting pin shaft steel which is composed of, by mass, 0.38%-0.45% of C, 1.0%-1.2% of Mn, 0.8%-1.1% of Cr, 0.20%-0.35% of Si, not larger than 0.25% of Ni, not larger than 0.025% of S, smaller than 0.025% of P, 0.3%-0.5% of Mo, 0.2%-0.5% of V, and the balance Fe. The wear-resisting pin shaft has the advantages of being high in strength and hardness.

Owner:宁波瑞国精机工业有限公司

Metal material used for preparing flow passage component of slurry pump and preparation method of metal material

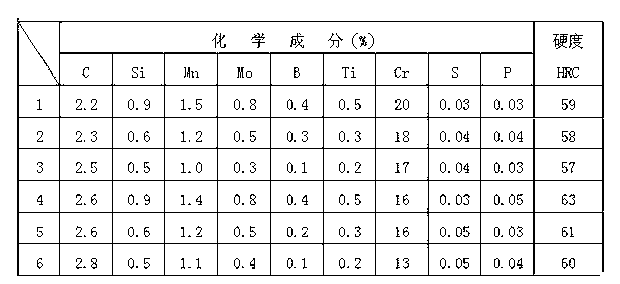

The invention discloses a metal material used for preparing a flow passage component of a slurry pump, which comprises the following components in percentage by weight: 2.2-2.8% of C, 13-20% of Cr, 0.5-1.0% of Si, 1.0-1.5% of Mn, 0.3-0.8% of Mo, 0.1-0.4% of B, 0.2-0.5% of Ti, less than 0.1% of S, less than 0.1% of P, and the balance of iron. The invention also provides a method for preparing the flow passage component by using the materials. The method comprises the following steps of: melting pig iron, waste steel and the like in a furnace; after melting clearly, adding ferromolybdenum and the like; regulating the components and heating, adding ferrotitanium and ferroboron, discharging and casting; shaping and machining; performing thermal treatment to the cast, cooling in air, and tempering. The metal material contains a large amount of alloy elements, the base rigidity is improved, the carbide is protected against untimely breaking and stripping; and the ratio of the alloy-alloy carbide is enhanced, and the alloy carbide is high in rigidity, excellent in wearing resistance effect and low in cost.

Owner:SHIJIAZHUANG IND PUMP FACTORY CO LTD

High-gloss, polyvinylidene fluoride-based coating systems and methods

ActiveCN101754852ALimit contentImproves blush resistancePretreated surfacesSpecial surfacesThermoplasticPolymer science

Solutions of polyvinylidene resins with very high vinylidene difluoride content in lactam solvent systems and their uses to form high gloss coatings, especially high gloss clear coatings. The present invention also provides coated articles incorporating these coatings. Advantageously, polyvinylidene fluoride (PVDF) resins with sufficiently high vinylidene difluoride content, as well as a wide variety of thermoplastic and thermosetting resins useful in the practice of the present invention, can be easily dissolved in and then stay dissolved in lactam solvents. Conveniently, these solutions may be prepared at room temperature. The ability to coat such PVDF resins from solution, rather than from dispersions, is a key factor leading to the high gloss characteristics provided by many embodiments of the present invention.

Owner:SWIMC LLC

Machining method for high-temperature-resisting and high-wear-resisting conveying chain

InactiveCN111020391ALimit contentIncrease contentConveyorsFurnace typesChemical compositionWear resistance

The invention relates to a machining method for a high-temperature-resisting and high-wear-resisting conveying chain. The conveying chain comprises a chain plate and a pin shaft. The pin shaft is madeof wear-resisting pin shaft steel, and the wear-resisting pin shaft steel comprises the following chemical components including, by mass percent, 1.0%-1.2% of Mn, 0.8%-1.1% of Cr, 0.38%-0.45% of C, smaller than 0.025% of P, 0.3%-0.5% of Mo, 0.2%-0.35% of Si, 0.2%-0.5% of V, smaller than or equal to 0.25% of Ni, smaller than or equal to 0.025% of S and the balance Fe. The conveying chain manufactured through the method has high high-temperature-resisting performance and high wear-resisting performance and is suitable for being used in the metallurgical industry.

Owner:常州常超模具有限公司

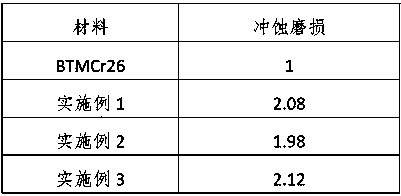

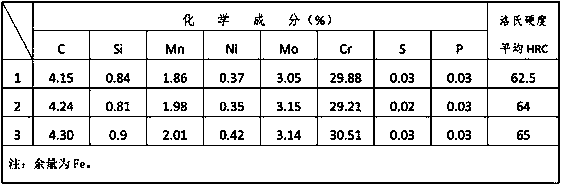

A kind of ultra-high wear-resistant hypereutectic high-chromium cast iron material, preparation method and application thereof

ActiveCN110079725BImprove toughnessImprove yieldProcess efficiency improvementCarbideWear resistance

The invention relates to an ultra-high wear-resistant hypereutectic high chromium cast iron material which comprises the following chemical components in percentage by mass: 4.0-5.0% of C, 25-35% of Cr, 0.5-1.0% of Si, 1.5-2.5% of Mn, less than or equal to 1% of Ni, 2-4% of Mo, and the balance Fe. The invention also relates to a preparation method of the ultra-high wear-resistant hypereutectic high chromium cast iron material, and relates to a smelting technology and an application of stable production of slurry pump flowing parts. Compared with BTMCr26 and Cr15Mo3 materials, the ultra-high wear-resistant hypereutectic high chromium cast iron material has a high carbon content and a high chromium content and a large amount of carbides, and the wear resistance of the material can be effectively improved.

Owner:SHIJIAZHUANG IND PUMP FACTORY CO LTD

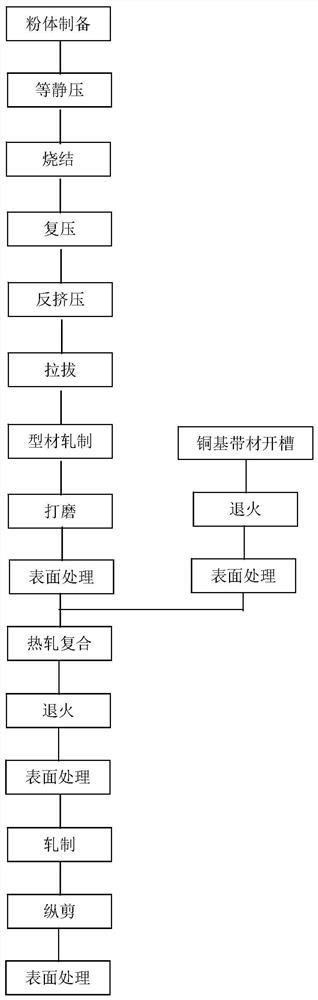

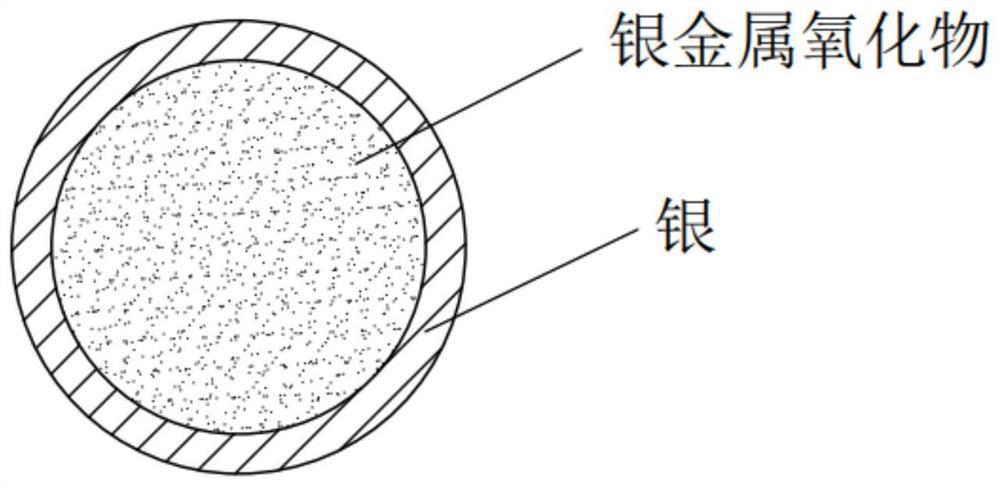

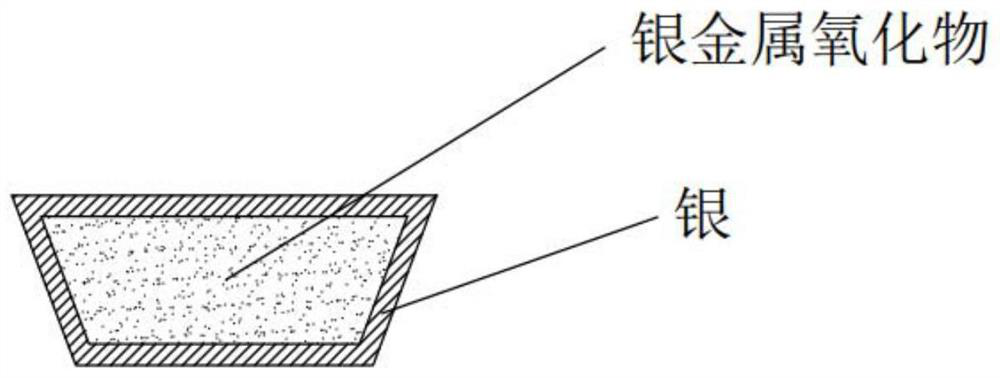

Silver metal oxide inlaid composite strip and preparation method thereof

PendingCN114512359AImprove wettabilityEnhanced atomic diffusion effectCable/conductor manufactureContactsBonding strengthCopper

The preparation method comprises the following steps: preparing a special-shaped strip with a trapezoidal cross section by taking a silver metal oxide composite silver core-spun wire as a raw material, grinding to remove a silver layer on the lower bottom surface of the trapezoidal cross section, and matching with a copper-based strip with a slotted trapezoidal groove, so as to prepare the silver metal oxide embedded composite strip. And the silver metal oxide inlaid composite strip is prepared after hot rolling compounding. According to the invention, the bonding strength between the silver metal oxide and the copper-based material can be effectively improved, especially the bonding strength of the bonding interface between the silver metal oxide of the vertical working surface of the inlaid composite strip and the copper-based material, and the interface is prevented from cracking in the bending forming process.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

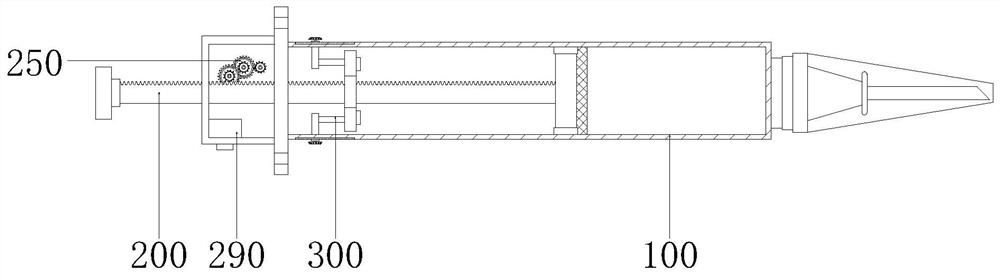

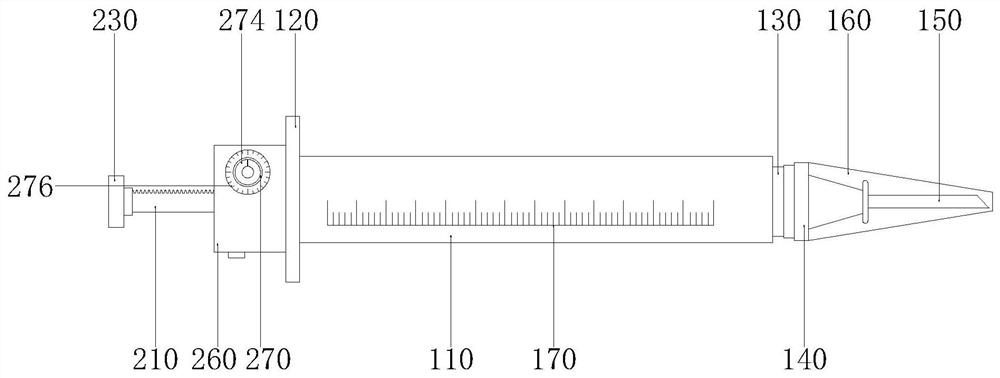

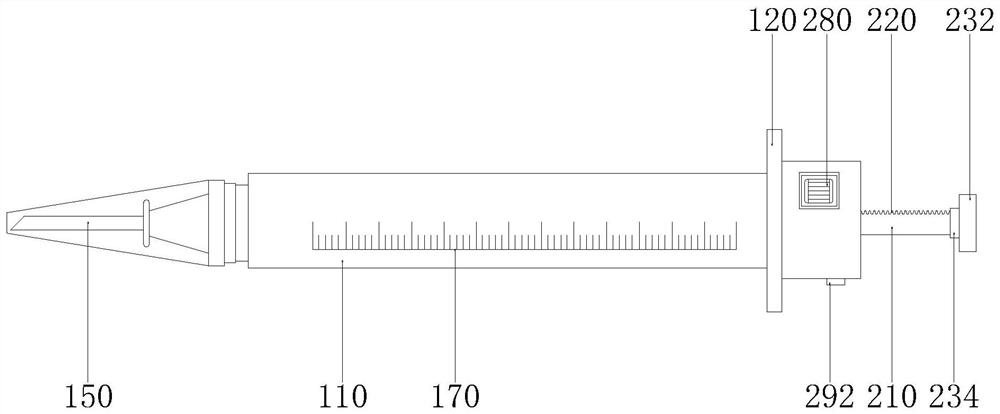

Quantitative injector

PendingCN112773979APrecise flow controlControl flowAutomatic syringesInfusion needlesPharmacy medicinePATIENT PHYSICAL

The invention provides a quantitative injector, and belongs to the technical field of medical instruments. The quantitative injector comprises a shell assembly, an injection pushing assembly and a limiting adjusting assembly. A protruding block is connected to one end of the shell, a communicating pipe is connected to the other end of the shell, a connecting piece is communicated with the communicating pipe, a piston piece is arranged between a push rod and the shell, a rotating piece is arranged on one side of the outer portion of a mounting shell, and the rotating piece is connected with a speed reducing piece; an adjusting bolt is connected between the shell and a connecting rod, a supporting plate is connected with the other end of a supporting rod, and the limiting baffle is connected to one side of the supporting plate. According to the invention, the flow and the speed of liquid medicine injection can be accurately controlled, the adverse effect on the physical condition of a patient caused by too fast injection of the medicine can be reduced, and meanwhile, the content of extracted medicine can be effectively controlled.

Owner:THE FIRST MEDICAL CENT CHINESE PLA GENERAL HOSPITAL

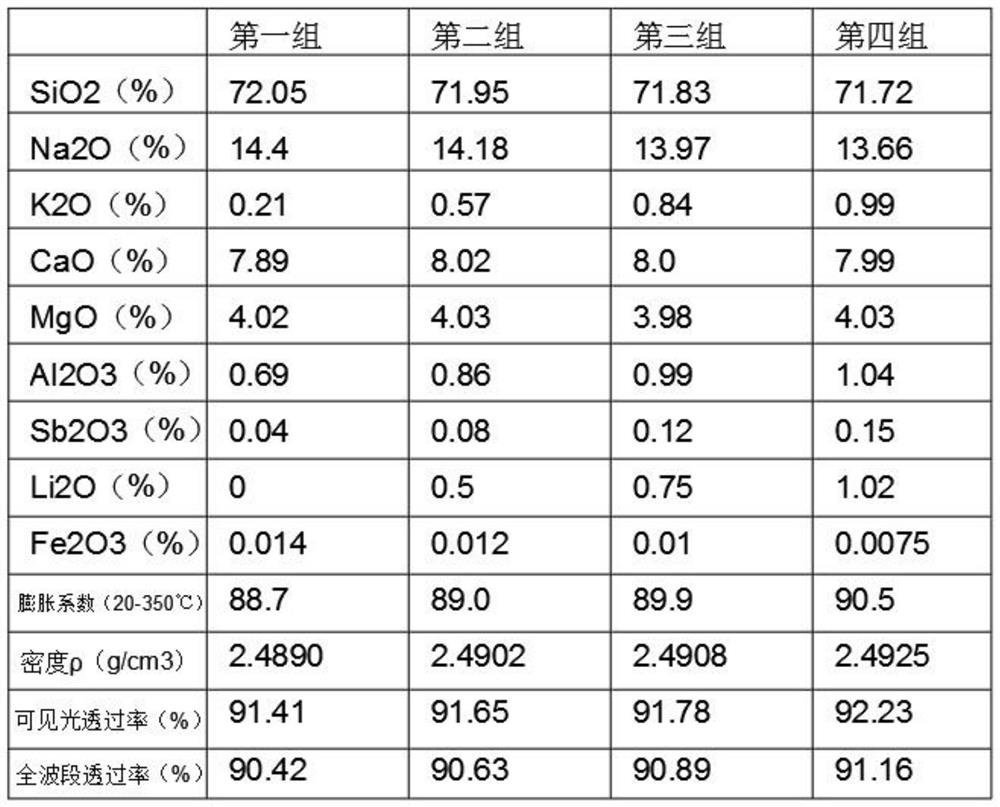

Solar ultra-white float photo-thermal glass and manufacturing method thereof

The invention relates to the technical field of glass, and discloses solar ultra-white float photo-thermal glass, which is characterized by comprising the following raw materials in parts by weight: 68-75 wt% of SiO2; al2O3: 0.3 wt% to 2.0 wt%; na2O: 12 wt% to 15.5 wt%; k2O: 0 wt% to 2 wt%; caO: 5 wt% to 11 wt%; sb2O3: 0.05 wt% to 0.5 wt%; mgO: 1 wt%-5 wt%; li2O: 0.1 wt% to 2.0 wt%; fe2O3: 1t; 0.01 wt% of the total weight; sO3: 0 wt% to 1 wt%; raw materials for forming the components comprise low-iron quartz sand, dolomite, limestone, aluminum hydroxide, mirabilite, sodium carbonate, potassium carbonate and sodium pyroantimonate. On the basis of common low-iron sodium-calcium silicate, various conventional sodium-calcium silicate components are optimized, the contents of CaO, MgO and Al2O3 are limited, and meanwhile, a small amount of new components such as Li2O, K2O and Sb2O3 are introduced into the glass to meet the requirements of a photo-thermal power generation glass substrate, so that the requirements of high transmittance and high reflectivity are met; the requirements of the photo-thermal power generation glass substrate are met, and the practicability is high.

Owner:河南安彩光热科技有限责任公司

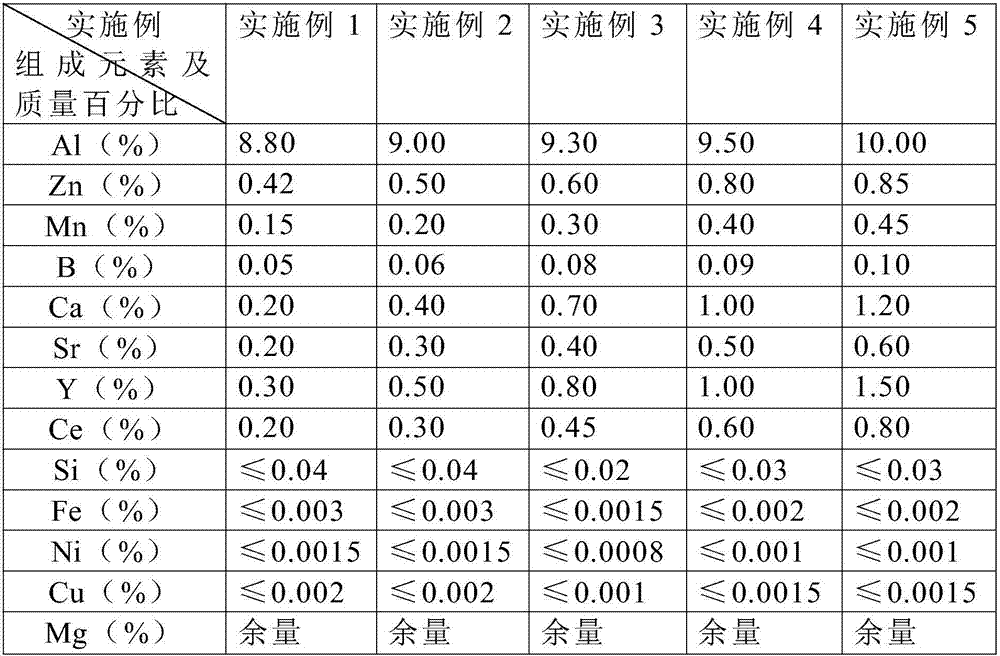

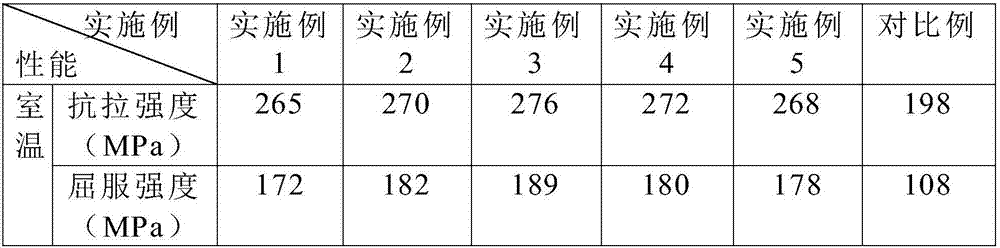

A kind of reducer gearbox end cover and preparation method thereof

ActiveCN106041015BImprove high temperature performanceImprove mechanical propertiesGearing detailsSolution treatmentRoom temperature

The invention relates to a reducer gearbox end cover, in particular to a reducer gearbox end cover and a preparing method thereof and belongs to the technical field of alloy materials. The reducer gearbox end cover comprises, by mass percent, 8.80%-10.00% of Al, 0.42%-0.85% of Zn, 0.15%-0.45% of Mn, 0.05%-0.10% of B, 0.20%-1.20% of Ca, 0.20%-0.60% of Sr, 0.30%-1.50% of Y, 0.20%-0.80% of Ce, smaller than or equal to 0.04% of Si, smaller than or equal to 0.003% of Fe, smaller than or equal to 0.0015% of Ni, smaller than or equal to 0.002% of Cu and the balance Mg. The invention particularly discloses the preparing method of the reducer gearbox end cover. Due to the reasonable compatibility of all the components and reasonable setting of technological parameters and due to the adoption of the method of composite solution treatment, the performance of the reducer gearbox end cover is further improved, the reducer gearbox end cover can have good comprehensive performance both under the room temperature and the high temperature, the requirement for the performance of the reducer gearbox end cover is met, and the service life of a reducer gearbox is prolonged.

Owner:NINGBO SHENGJING TRANSMISSION SCI & TECH CO LTD

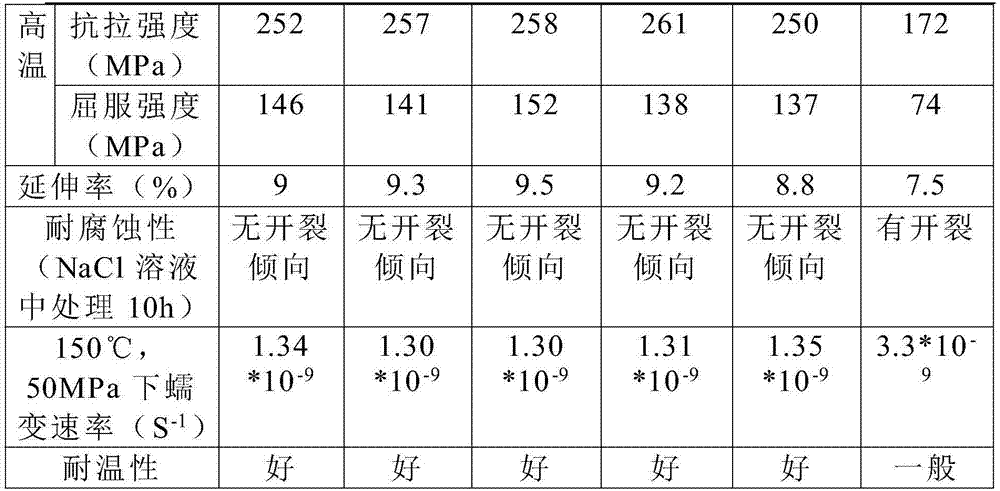

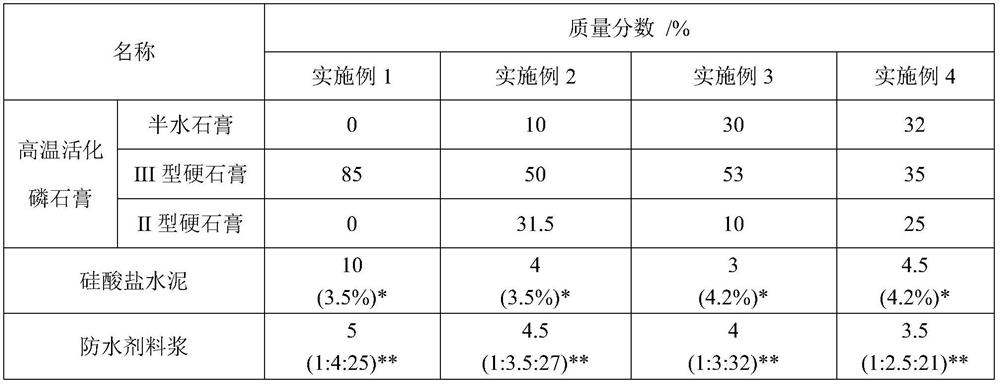

Preparation method of phosphogypsum roadbed material based on high temperature activation and hydraulic hardness improvement

The invention proposes a method for preparing a phosphogypsum roadbed material based on high-temperature activation and improved hydraulicity, which relates to the field of roadbed materials. In the present invention, phosphogypsum with a free moisture content of 7%-20% is firstly calcined at high temperature into a high-temperature product, and then the waterproofing agent slurry obtained by mixing silane coupling agent, polyvinyl alcohol and hot water is prepared, and finally the prepared high-temperature The product, waterproofing agent slurry and Portland cement are mixed according to the mass percentage of 85%-93%: 3.5%-5%: 3%-10%, and the phosphogypsum roadbed material is obtained by stirring evenly; , C 3 The mass fraction of mineral A in Portland cement is 2%-5%, and mineral admixtures containing aluminosilicate must not be mixed in Portland cement. The prepared phosphogypsum roadbed material has good strength, water stability and volume stability, and has simple preparation process, low production cost and wide source of raw materials.

Owner:四川绵筑新材料有限公司

A kind of turmeric drink and preparation method thereof

ActiveCN107996932BHigh dissolution rateLow content of harmful impuritiesNatural extract food ingredientsFood ingredient functionsBiotechnologyOrganic solvent

Owner:四川新磷环保技术有限公司

A kind of solid powder multi-component composite penetration agent and composite penetration process

ActiveCN109468581BFast migrationImprove carrying capacitySolid state diffusion coatingSurface cleaningOxidation resistant

The invention relates to a solid powder multi-element composite infiltration agent and a composite infiltration process, and belongs to the technical field of metal surface treatment. The composite infiltration agent is composed of a chromium source, a vanadium source, a boron source, nickel powder, an activating agent, a filling agent, an oxygen scavenger and a rare-earth infiltration enhancer. The composite infiltration agent has the effects of rapid infiltration speed, no pollution, improving the structural density of an infiltration layer, and avoiding the embrittlement of the infiltrationlayer. The composite infiltration process comprises the following steps of carrying out acid pickling activation pretreatment on a base body material, then burying the base body material into the composite infiltration agent, heating and preserving heat in a carbon-containing or nitrogen-containing atmosphere, and then carrying out quenching treatment after furnace cooling. According to the process, the method is simple, no pollution occurs, the infiltration speed is rapid, the infiltration agent is free of hardening, and the surface of an infiltrated workpiece is clean. The prepared composite infiltration layer is fine in the crystalline grains and compact in the structure, has a good gradient structure, has the toughness, the wear resistance, the corrosion resistance, the high-temperature oxidation resistance and the like, and can be applied to parts such as a tool, a mold, a bearing, and a gear.

Owner:GUANGDONG INST OF NEW MATERIALS

A method for efficient control of dioxins in waste incineration

The invention discloses a method for efficiently controlling dioxins in garbage incineration, which comprises the following steps: a. After blending the garbage with a chelating agent, the garbage is put into an incinerator for incineration; b. The flue gas generated in step a enters the flue gas for washing Tower, spray alkali solution for treatment; c. The flue gas treated in step b leaves the tower and sprays adsorbent, then collects fly ash through dust collector, and discharges gas. This method adopts corresponding measures to control dioxins in the front, middle and back stages of waste incineration treatment. The premixing before incineration reduces the source of chlorine in incineration, and the flue gas produced by incineration limits the formation of dioxins through washing. The required reactant content and catalyst activity, and the residual dioxins are stabilized by adsorption in the later stage, which realizes the overall efficient control of dioxins, avoids complicated equipment modification, and the cost is controllable.

Owner:SHANGHAI ENVIRONMENTAL & SANITARY ENG DESIGN INST CO LTD +1

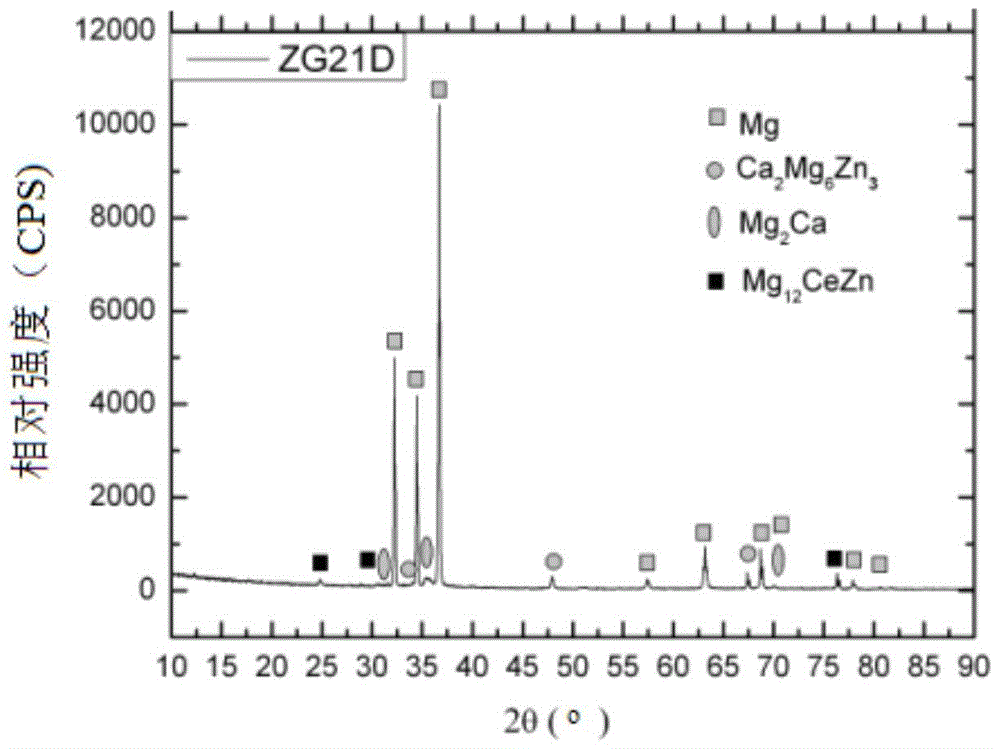

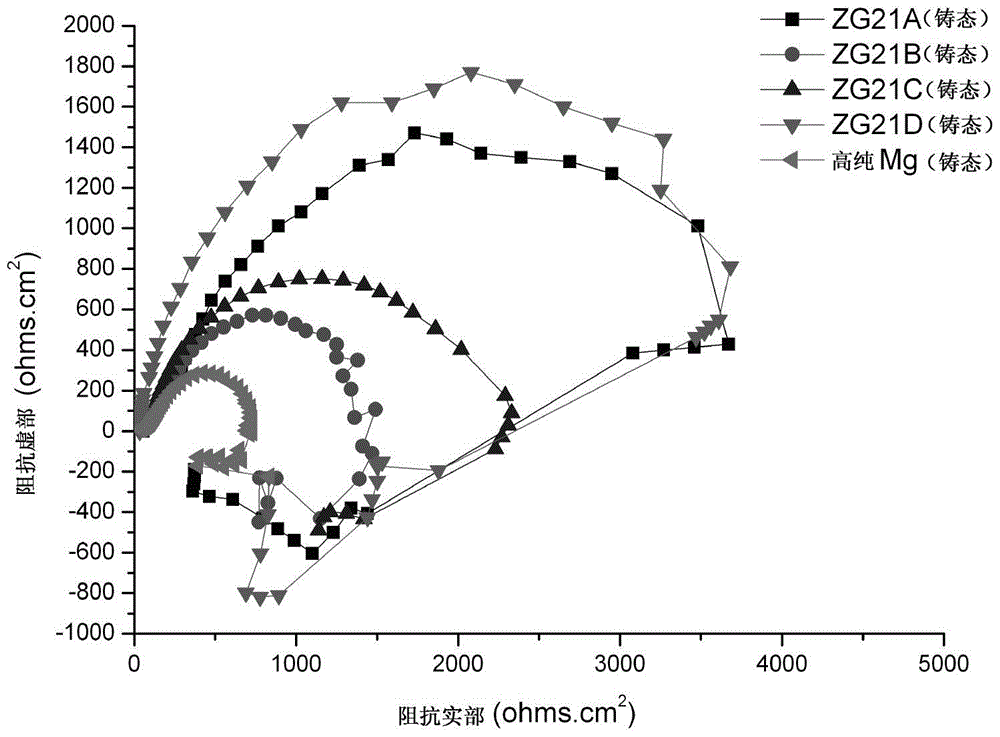

Dispersion strengthened medical mg-zn-ce-ca-mn alloy and preparation method thereof

InactiveCN103757511BImprove mechanical propertiesImprove corrosion resistanceProsthesisMg alloysBiocompatibility

Owner:南通河海大学海洋与近海工程研究院 +1

A rotary spray reflux bubble column to remove ship exhaust SO x s installation

ActiveCN105749710BAdd processing pathReduce rateGas treatmentDispersed particle separationBubble columnBuffer tank

The invention aims to provide a marine exhaust gas SOx removal device for a rotary spraying refluxing bubble tower. The marine exhaust gas SOx removal device comprises a washing tower, a NaOH solution storage cabin, a waste liquid buffer tank and waste liquid centrifugal treatment equipment; the washing tower comprises a washing tower outer layer cylinder; a washing tower inner layer cylinder and a spiral rising washing pipeline are arranged in the washing tower outer layer cylinder; an exhaust gas inlet, an exhaust gas outlet and a washing liquid outlet are respectively formed in the outer wall of the washing tower outer layer cylinder; the exhaust gas inlet is connected with a marine diesel engine exhaust pipe; the exhaust gas outlet is communicated with the atmosphere; the washing liquid outlet is communicated with the waste liquid buffer tank; the waste liquid buffer tank is connected with the waste liquid centrifugal treatment equipment; the waste liquid centrifugal treatment equipment is connected with each of an oil contamination storage cabin and a heavy residue storage cabin. According to the marine exhaust gas SOx removal device, SO2 in exhaust gas is subjected to washing treatment by adopting two technologies, namely a novel rotary spraying washing technology and a novel pneumatic stirring bubbling washing technology; the contact path between the washing liquid and the exhaust gas is increased; the acting time is prolonged; the acting area is increased, so that the exhaust gas is treated sufficiently.

Owner:HARBIN ENG UNIV

Manufacturing process of a load-bearing arm of a robot

The invention discloses a manufacturing process of a load-bearing arm of a robot hand. The load-bearing arm is divided into four parts and cast independently, and then assembled in a double-connected and fixed manner, and finally ion-nitrided. The invention can solve the shortcomings of the prior art, enhance the tolerance of the load-bearing arm and improve its service life.

Owner:宁夏巨能机器人股份有限公司

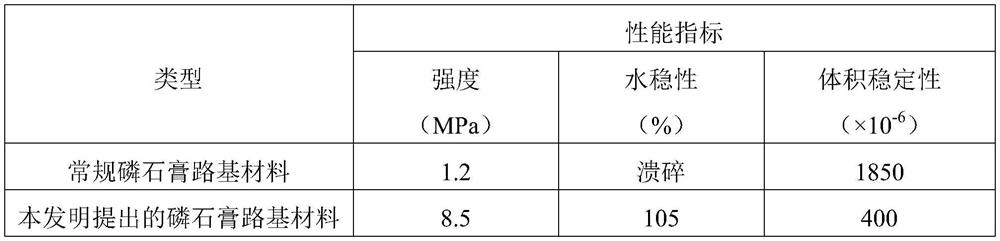

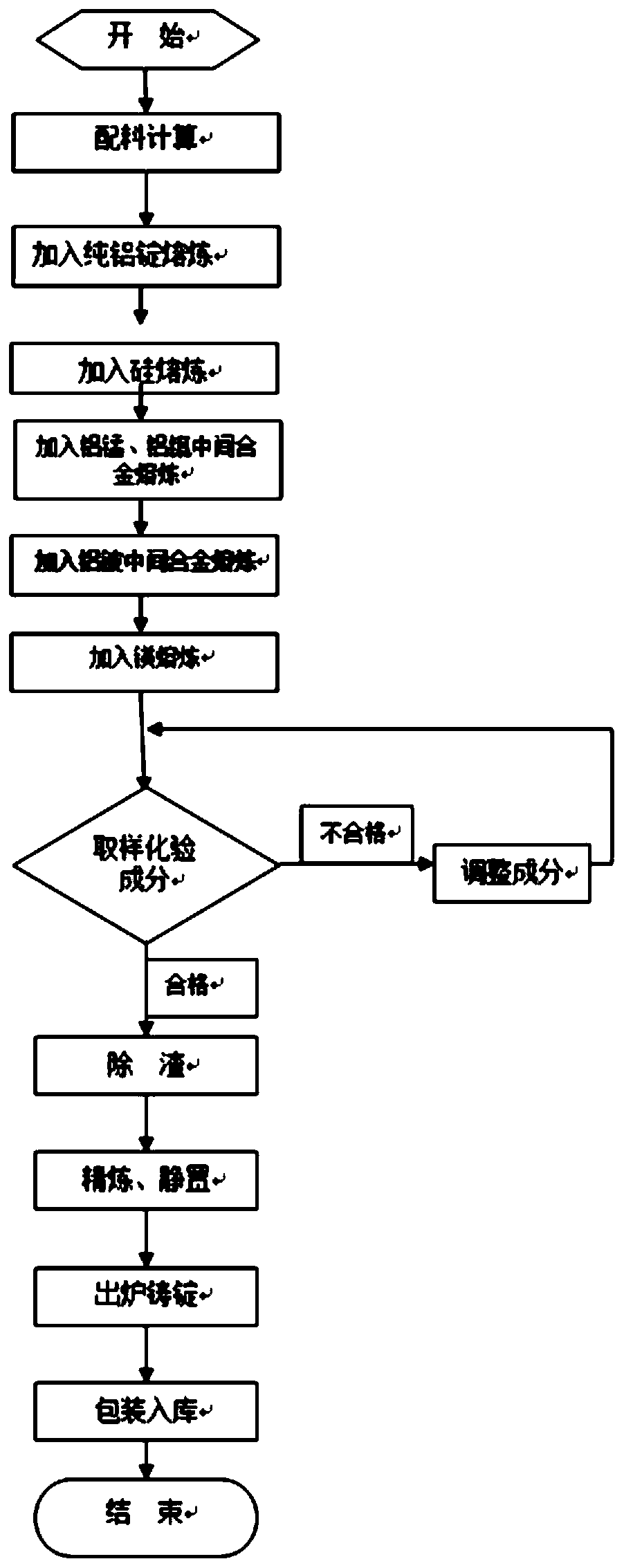

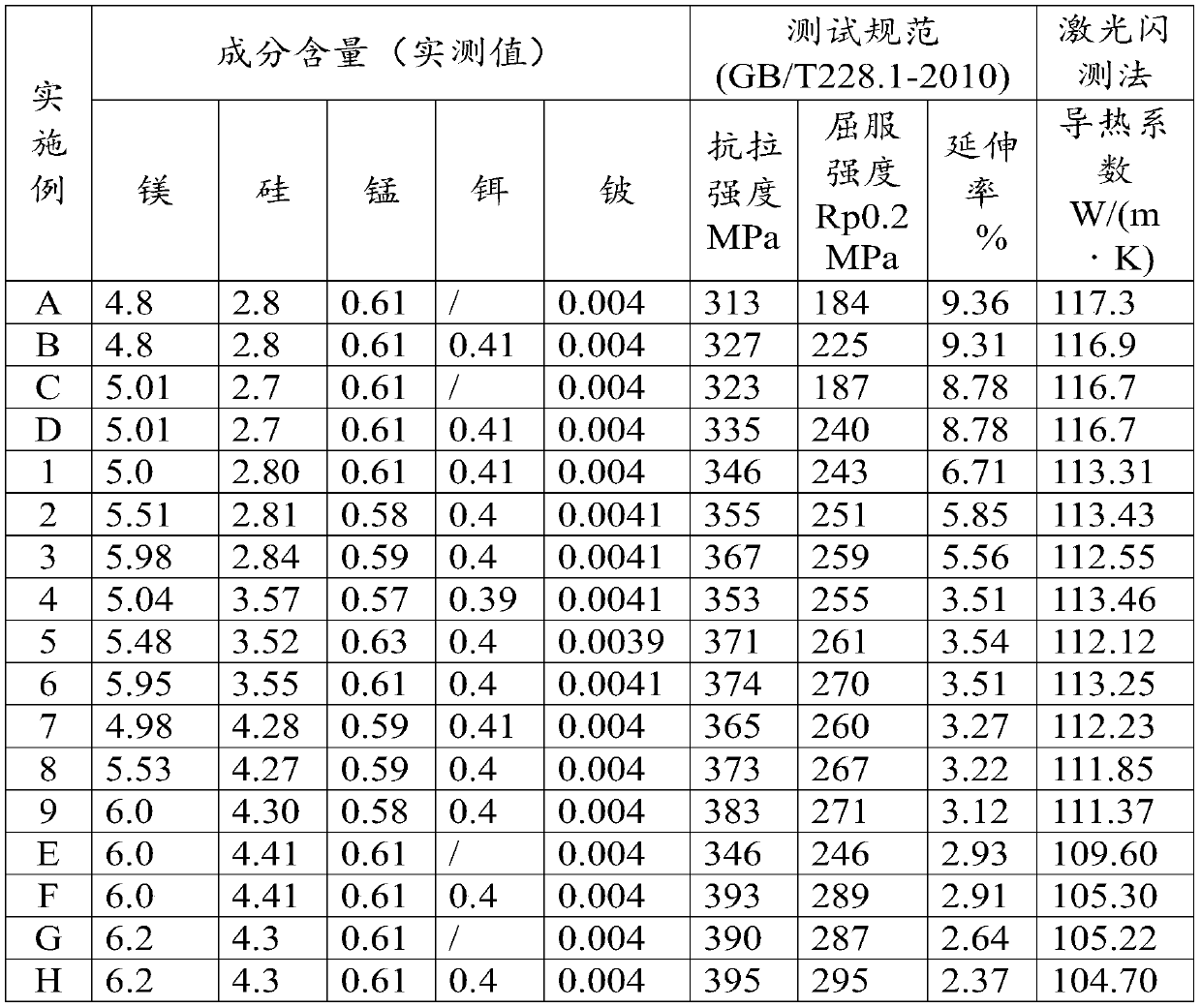

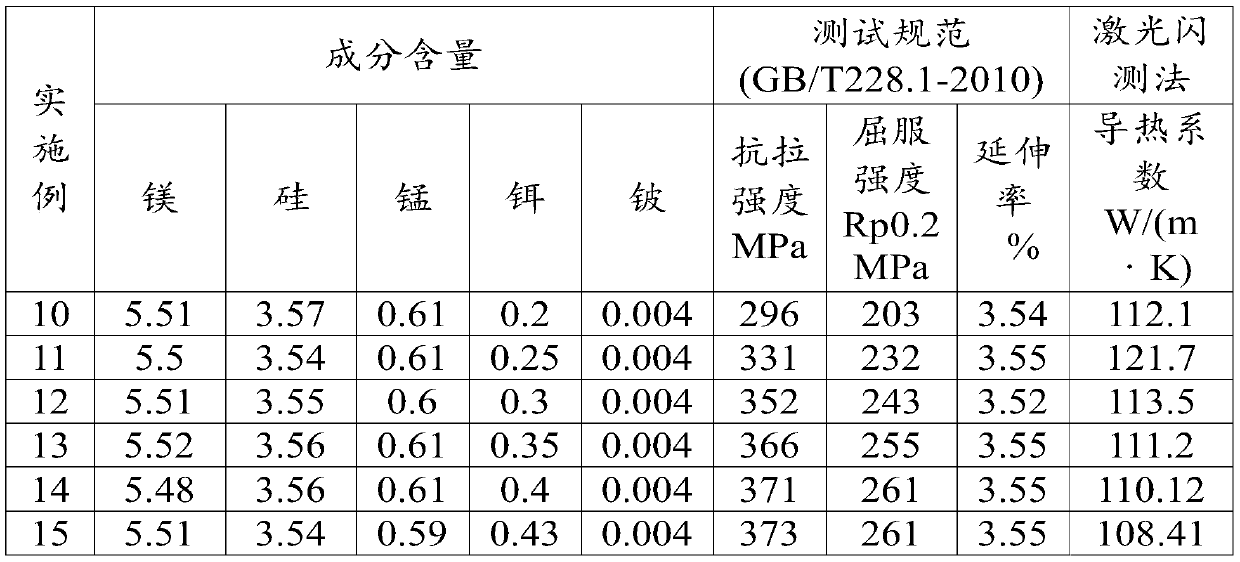

Die casting aluminum alloy

The invention discloses a die casting aluminum alloy. The die casting aluminum alloy comprises main components including, by mass percent, 5.0%-6.0% of Mg, 2.8%-4.3% of Si, 0.5%-0.7% of Mn, 0.36%-0.41% of Er, 0.003%-0.008% of Be and the balance Al and other inevitable impurity elements. The die casting aluminum alloy has the advantages that the yield strength is high, heat conduction performance is excellent, corrosion resistance is achieved, and the die casting and machining performance is excellent. The die casting aluminum alloy is high in strength and excellent in heat conduction performance and can be widely applied to the electronic industry, the electrical industry, the communication industry and the electromechanical industry.

Owner:江门市新会区新融金属制品有限公司

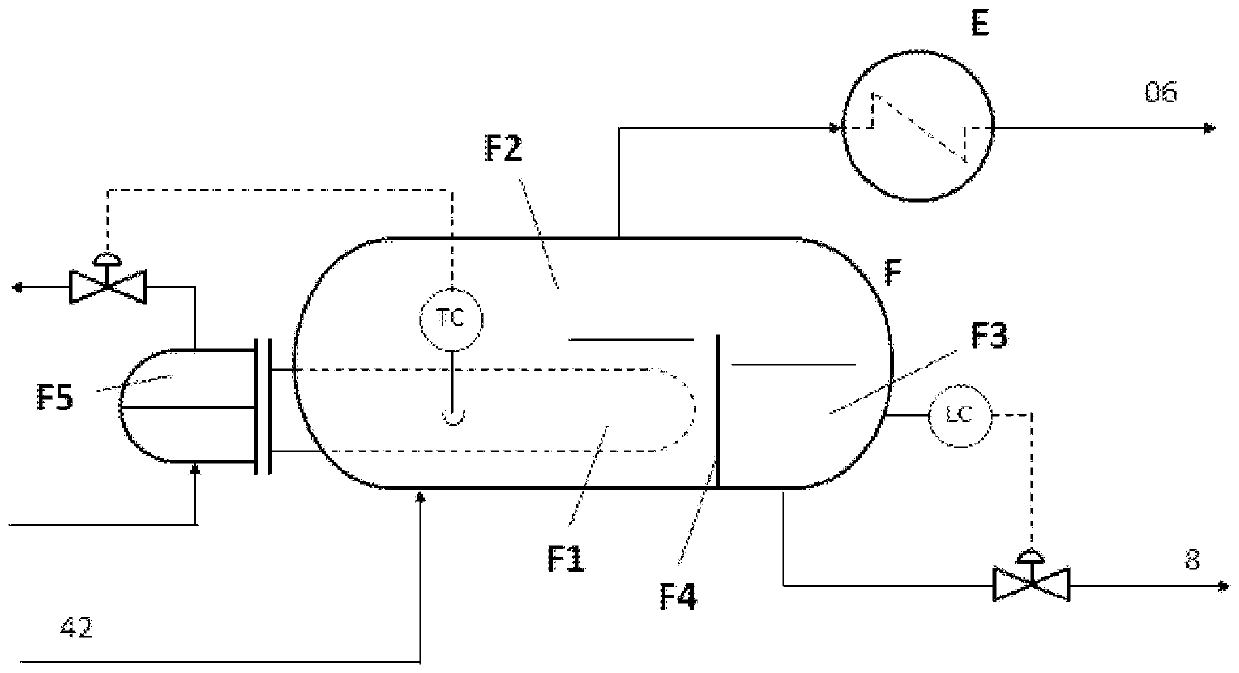

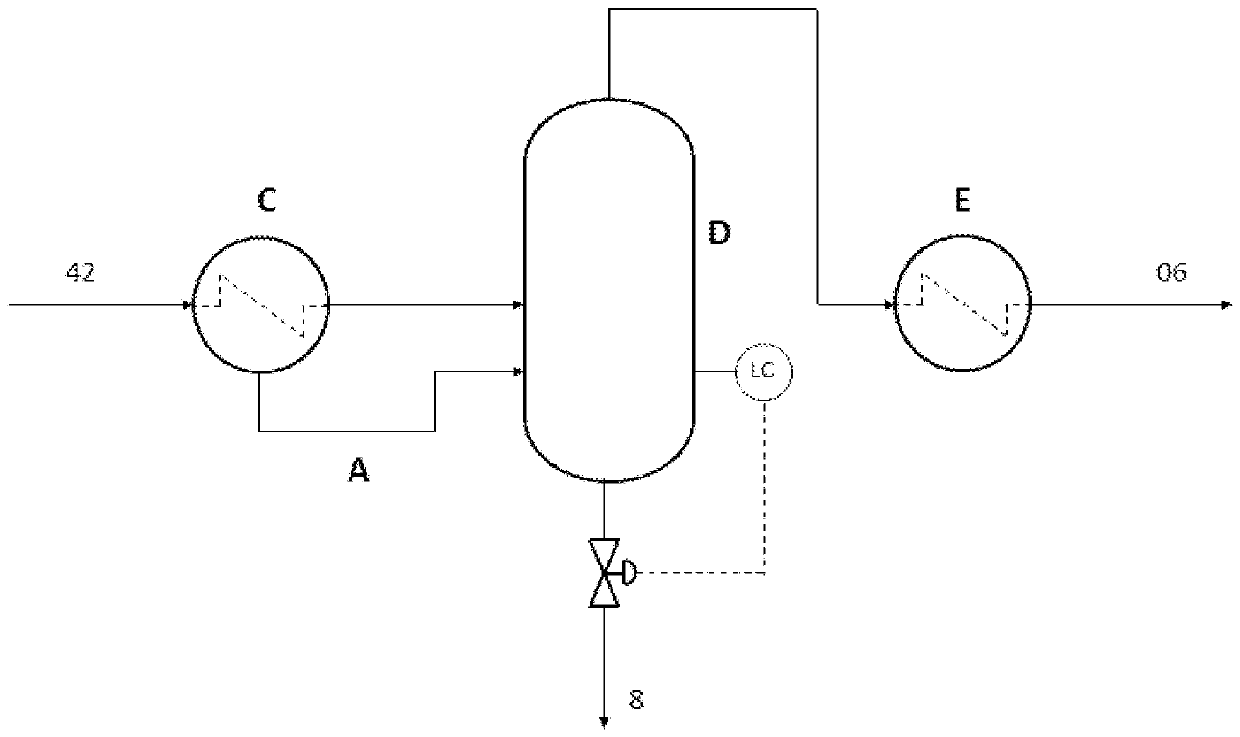

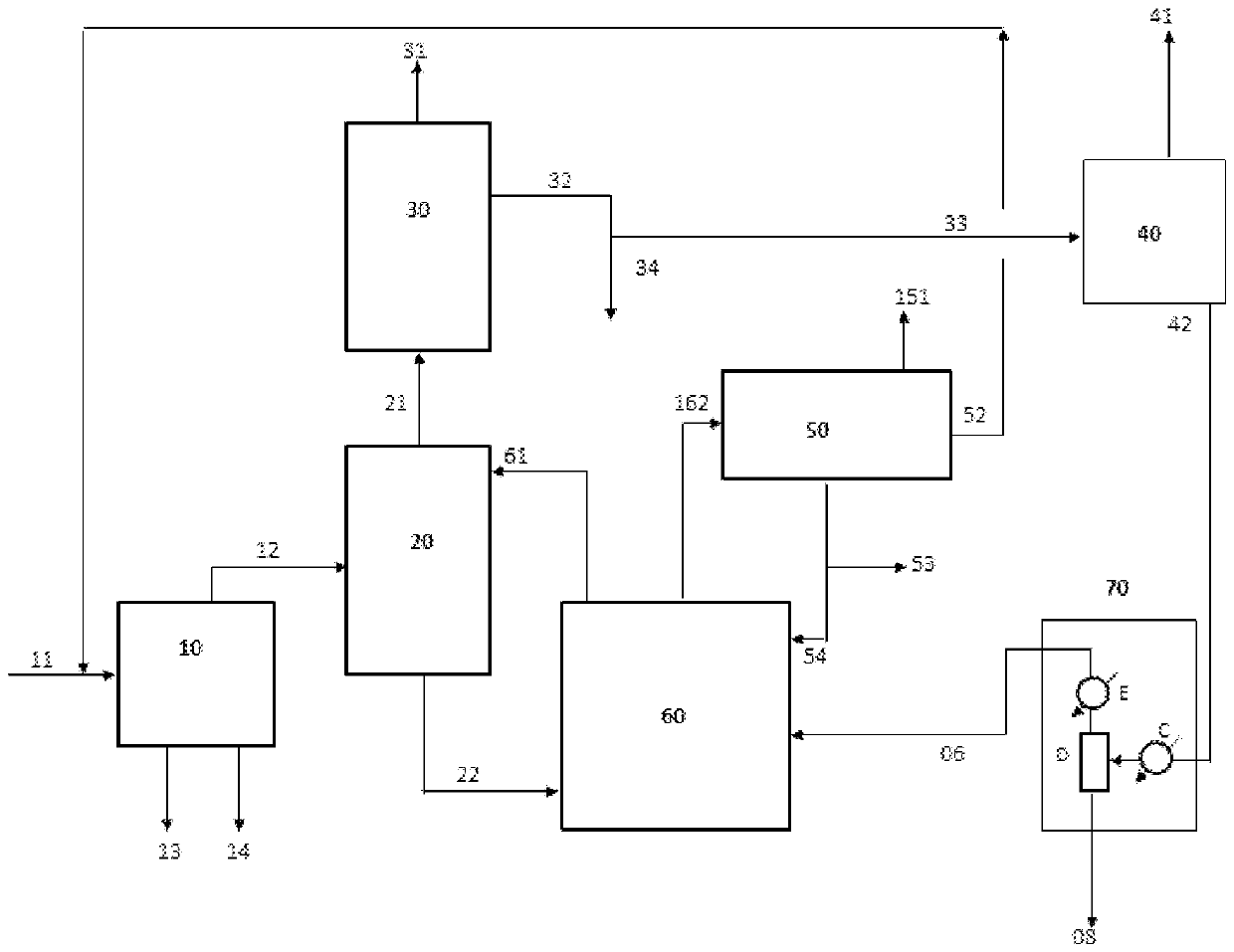

Process for dehydrating hydrocarbon-based gas

The invention discloses a process for dehydrating hydrocarbon-based gas. The present invention proposes to use a dry stream which is rich in C4 to C10 hydrocarbons as stripping agent for improving theregeneration of the liquid desiccant according to the invention. This dry stream rich in C4 to C10 hydrocarbons is extracted from the gas derived from the dehydration, for example during a step of extraction of NGL located downstream of the gas dehydration unit. The stream of stripping agent recovered at the outlet of the liquid desiccant regeneration unit may be recycled into the process of theinvention or sent to a unit external to the process according to the invention. For example, this stream of stripping agent recovered at the outlet of the regeneration unit is sent to a unit which canreceive wet condensates, such as a three-phase separation unit at the inlet of a crude gas processing plant, a condensate stabilization unit, etc.

Owner:AXENS SA

Electrochemical battery

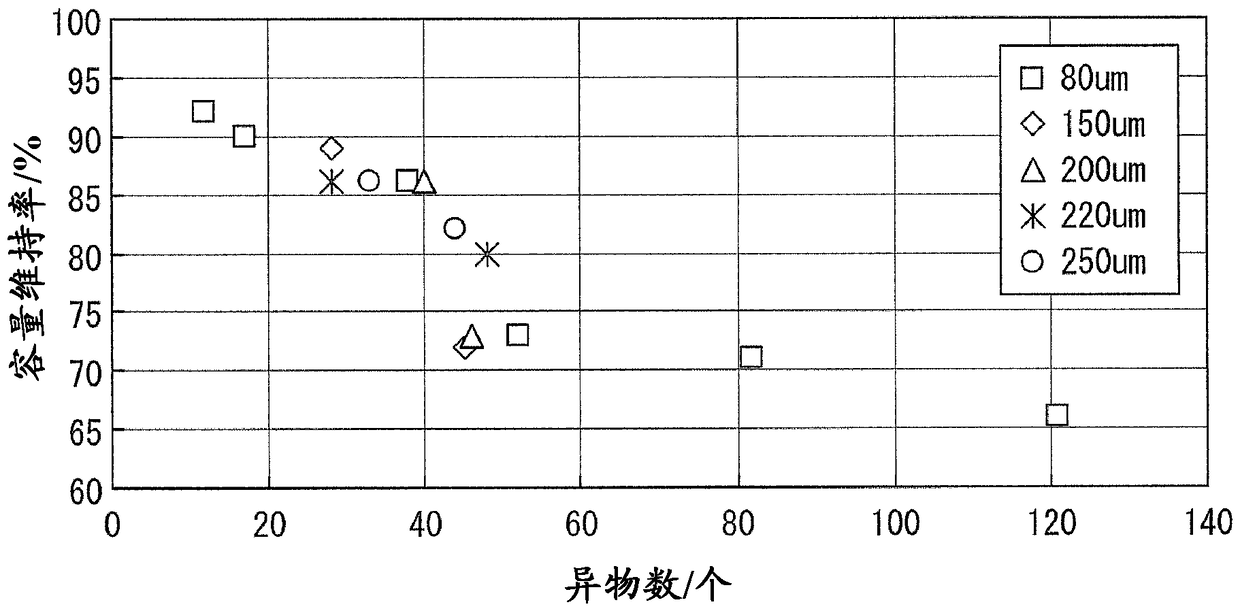

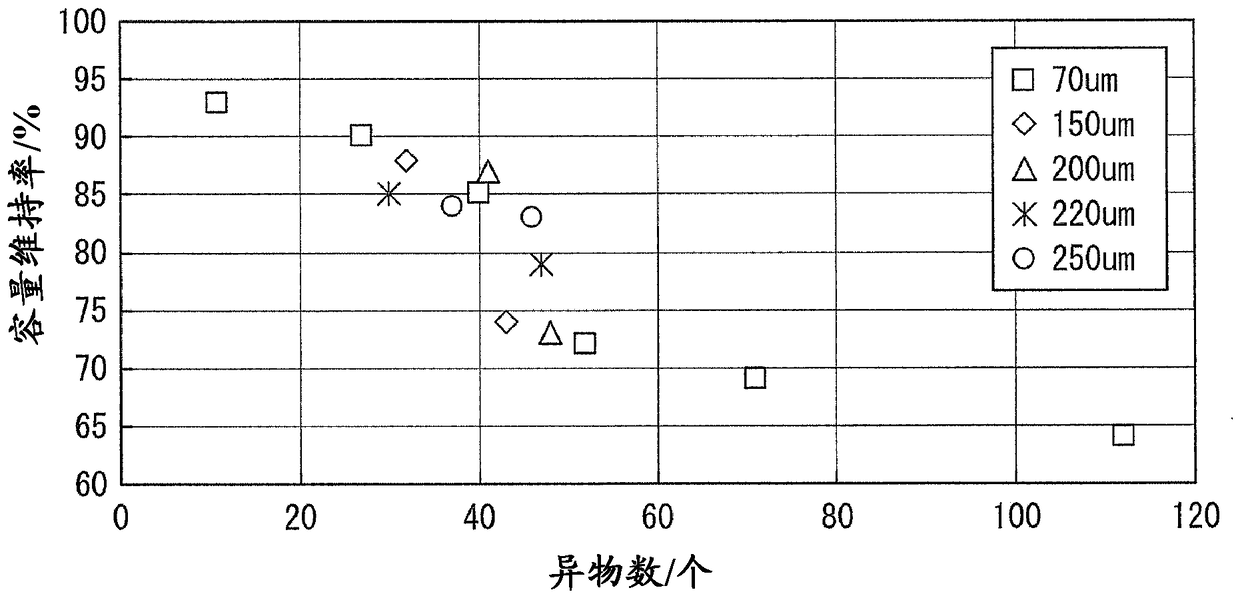

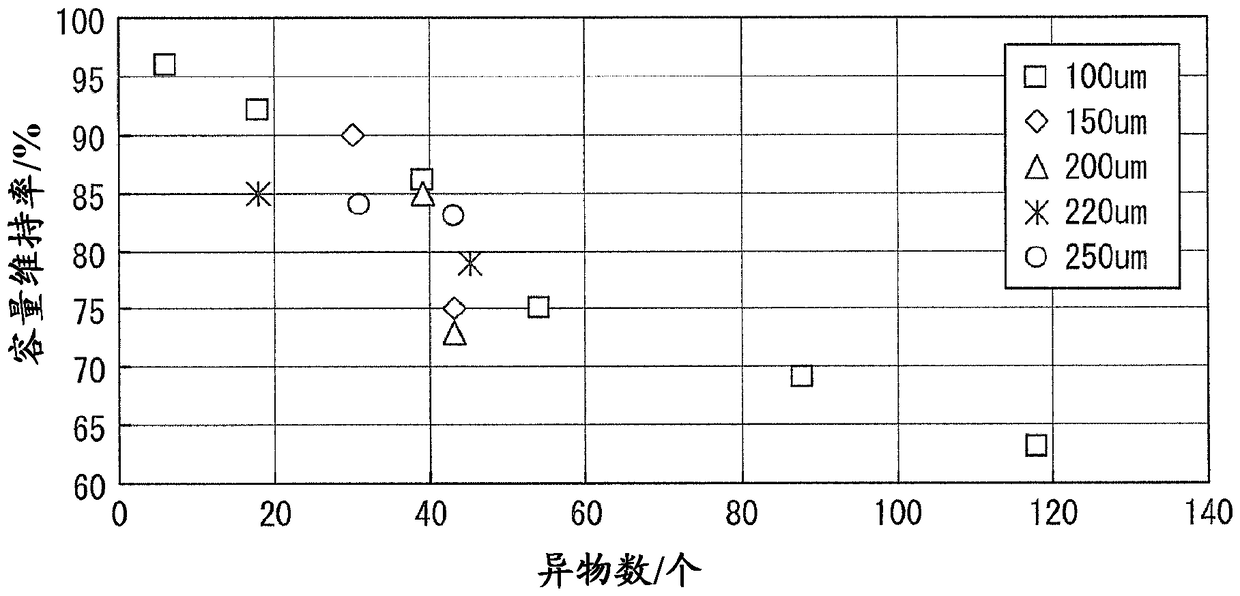

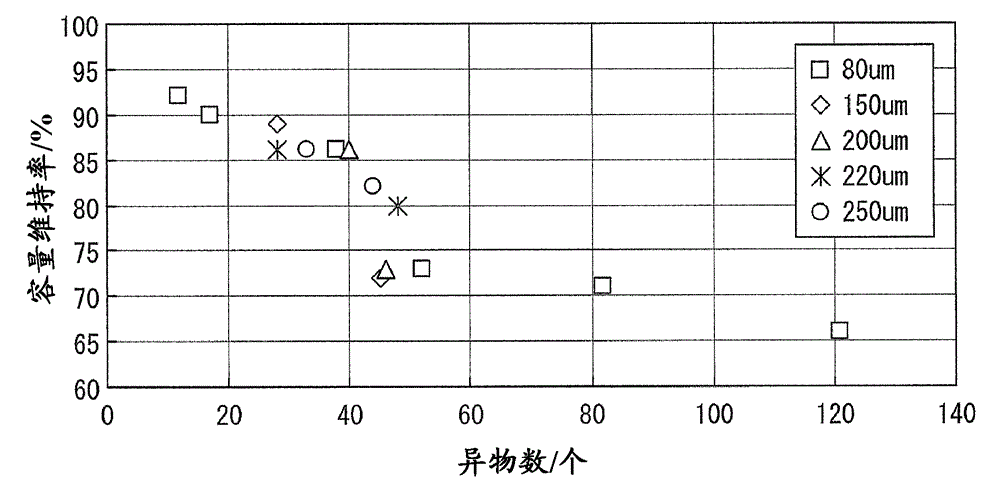

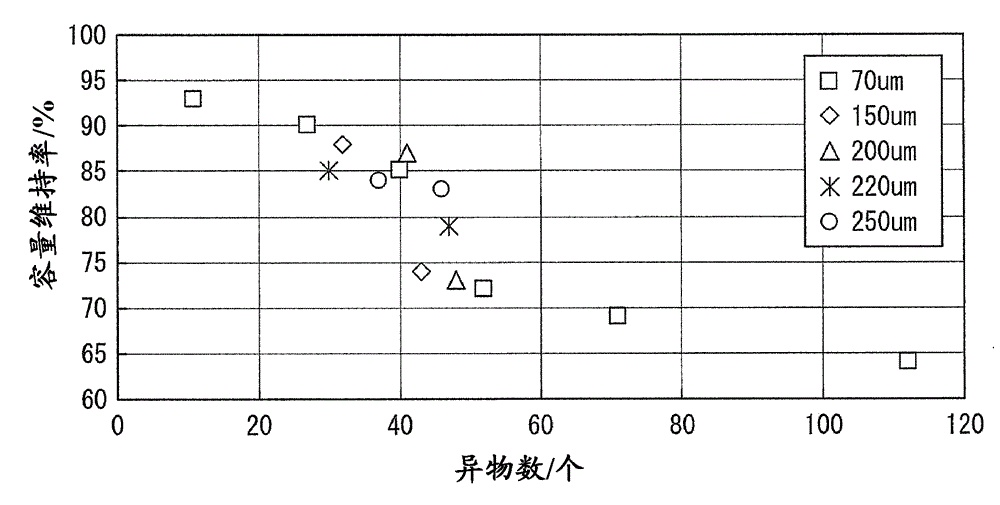

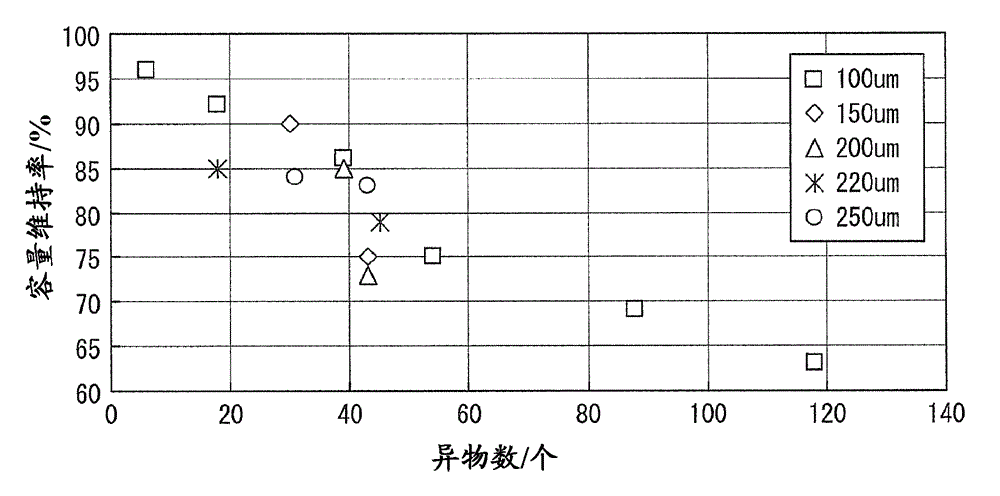

ActiveCN104051716BLimit contentSuppress mix-inHybrid capacitor electrodesFinal product manufactureForeign matterDischarge efficiency

The present invention provides reliable and easy identification / quantification of additives and foreign matter contained in the negative electrode, while reducing the amount of impurities mixed in the negative electrode, while suppressing the mixing of large-sized impurities, high reliability, charge and discharge efficiency and cycle life Electrochemical cells with excellent properties. The electrochemical cell is formed with positive pole (30), negative pole (40), electrolyte solution containing supporting electrolyte and non-aqueous solvent and separator (5), and the negative active material used in the negative pole (40) is SiOx (0< At least any one of x<2), Si, and C, in addition, the thickness of the negative electrode (40) is 200 μm or less, and in the transmission X-ray observation of the negative electrode (40) per 100 cm2 electrode area in planar observation, the negative electrode (40) The number of foreign substances with an average particle diameter of φ20 μm or more contained in the container is 40 or less.

Owner:SEIKO INSTR INC

Electrochemical cell

ActiveCN104051716AReduce the amount of mixingAvoid concentrationHybrid capacitor electrodesCell electrodesSupporting electrolyteDischarge efficiency

The invention provides an electrochemical cell. The additive in the negative electrode can be easily and reliably differentiated or identified / quantified from impurities, thus the amount of impurities in the negative electrode can be reduced, and large-sized impurities can be prevented from entering the negative electrode, so the electrochemical cell has the advantages of high reliability, high charge / discharge efficiency, and extremely long circulation service life. The electrochemical cell has a positive electrode (30), a negative electrode (40), electrolyte containing electrolyte-supportive solvents and non-aqueous solvents, and a partition plate (5). The active material in the negative electrode (40) is composed of at least one component of SiOx (0<x<2), Si, and C, the thickness of the negative electrode (40) is less than 20 [mu]m, the number of particles with an average size phi of 20 [mu]m or more is less than 40 on each 100 cm2 of electrode area in the negative electrode (40) when the negative electrode (40) is observed on a plane under transmission X rays.

Owner:SEIKO INSTR INC

A wear-resistant pin and its processing method

The invention belongs to the technical field of pin shaft machining, and relates to a wear-resisting pin shaft and a machining method thereof. The wear-resisting pin shaft and the machining method thereof solve the problems that an existing pin shaft is low in strength and hardness. The wear-resisting pin shaft is formed by machining wear-resisting pin shaft steel which is composed of, by mass, 0.38%-0.45% of C, 1.0%-1.2% of Mn, 0.8%-1.1% of Cr, 0.20%-0.35% of Si, not larger than 0.25% of Ni, not larger than 0.025% of S, smaller than 0.025% of P, 0.3%-0.5% of Mo, 0.2%-0.5% of V, and the balance Fe. The wear-resisting pin shaft has the advantages of being high in strength and hardness.

Owner:宁波瑞国精机工业有限公司

A kind of anti-adhesion alginate dressing and preparation method thereof

ActiveCN106176045BNot easy to get inSuitable humidityAdhesive dressingsAbsorbent padsSurface layerBiomedical engineering

The invention discloses anti-sticking alginate dressing and a preparation method thereof. The alginate dressing comprises a bottom layer, a water-absorbing layer, a surface layer and an anti-sticking layer, wherein the alginate dressing is of a layered structure; the bottom layer, the water-absorbing layer, the surface layer and the anti-sticking layer are sequentially overlapped to form the layered structure; breathable holes are formed in the bottom layer; the hole diameters of the breathable holes are smaller than or equal to 0.22 micron. The breathable holes are formed in the bottom layer of the dressing, and the hole diameters of the breathable holes are smaller than or equal to 0.22 micron, so that the dressing has a breathable function, and bacteria are unlikely to enter; the alginate dressing provided by the invention is further provided with the water-absorbing layer, and the provided water-absorbing layer can maintain proper humidity of a wound, so that wound healing is facilitated.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com