Anti-sticking alginate dressing and preparation method thereof

An alginate and anti-adhesion technology, which is applied in viscous dressings, dressings, medical science, etc., can solve the problems of secondary wound damage and wound adhesion, and achieve the effects of simplifying the production process, increasing production speed, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

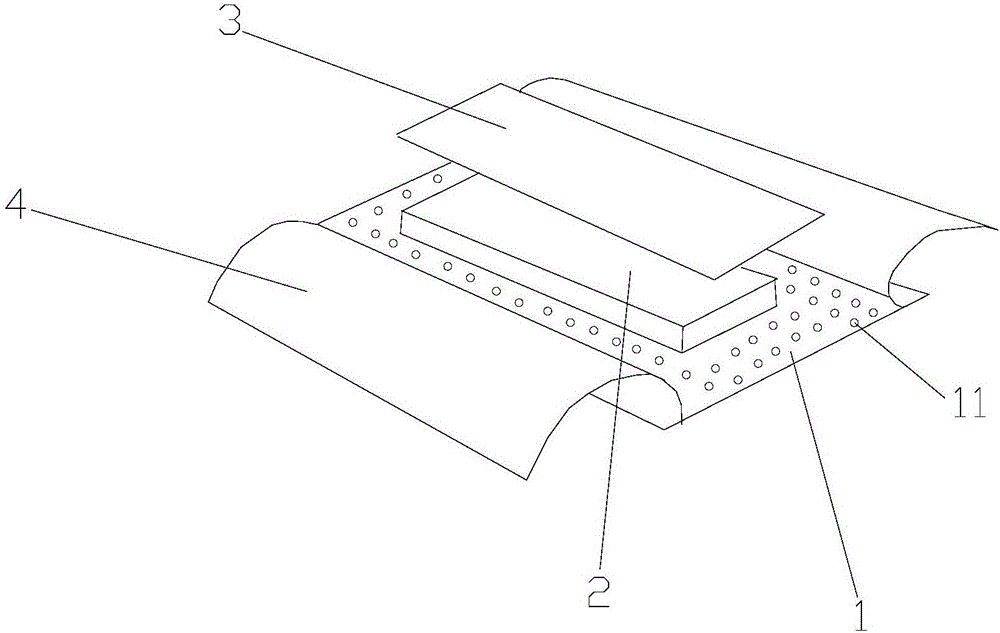

[0030] Such as figure 1 Shown, a kind of anti-adhesion alginate dressing comprises: bottom layer 1, water-absorbing layer 2, surface layer 3, anti-sticking layer 4; Described alginate dressing is layered structure, bottom layer 1, water-absorbing layer 2, surface Layer 3 and anti-adhesive layer 4 overlap in sequence to form a layered structure; the shape of the bottom layer 1 is a rounded rectangle; the bottom layer 1 is provided with air holes 11, and the diameter of the air holes 11 is less than or equal to 0.22 microns.

[0031] The side of the bottom layer 1 close to the water-absorbing layer 2 is sticky, the area of the surface layer 3 is larger than the area of the water-absorbing layer 2, and the surface layer 3 is bonded to the bottom layer 1 so that the water-absorbing layer 2 is clamped and fixed between the surface layer 3 and the bottom layer 1 between. This arrangement enables the water-absorbing layer 2 to be stably fixed between the surface layer 3 and the ...

Embodiment 2

[0036] A preparation method of an anti-adhesion alginate dressing, comprising the steps of:

[0037] (1) Prepare calcium alginate solution and polylactic acid solution respectively, according to the mass ratio of calcium alginate and polylactic acid is 4:1, after mixing calcium alginate solution and polylactic acid solution, stir evenly, let stand for 20h, obtain spinning Stock solution, spare;

[0038] (2) At normal temperature, utilize electrospinning equipment to carry out electrospinning to the spinning dope, adjust the speed of the micro injection pump to be 0.1 ml / hour, adjust the voltage of the high voltage generator to be 10KV, and adjust the receiving distance of the receiving drum to be 10 centimeter, by using a power device to control the horizontal movement and rotation of the receiving drum, the horizontal moving speed of the receiving drum is 0.001mm / s, and the rotating speed of the receiving drum is 100r / s during spinning, to obtain an alginate composite film, a...

Embodiment 3

[0041] A preparation method of an anti-adhesion alginate dressing, comprising the steps of:

[0042] (1) prepare alginate solution and polylactic acid solution respectively, include calcium alginate and sodium alginate in the described alginate, the mass ratio of calcium alginate and sodium alginate is 2:3; The mass ratio of lactic acid is 1.5:1. After mixing the alginate solution and the polylactic acid solution, stir evenly, and let stand for 28 hours to obtain the spinning stock solution, which is set aside;

[0043] (2) At normal temperature, utilize electrospinning equipment to carry out electrospinning to spinning stock solution, the speed of regulating micro-injection pump is 10 milliliters / hour, the voltage of regulating high voltage generator is 45KV, and the receiving distance of regulating receiving cylinder is 40 centimeter, by controlling the horizontal movement and rotation of the receiving drum with a power device, the horizontal moving speed of the receiving drum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com