Novel reinforced tire

A technology for reinforcing tires and tires, which is applied to tire parts, reinforcing layers of pneumatic tires, transportation and packaging, etc. It can solve problems such as air leakage, failure to drive normally, and easy to be nailed to tires by iron nails, so as to prolong the service life , stable driving life, and the effect of preventing foreign matter from entering the tire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

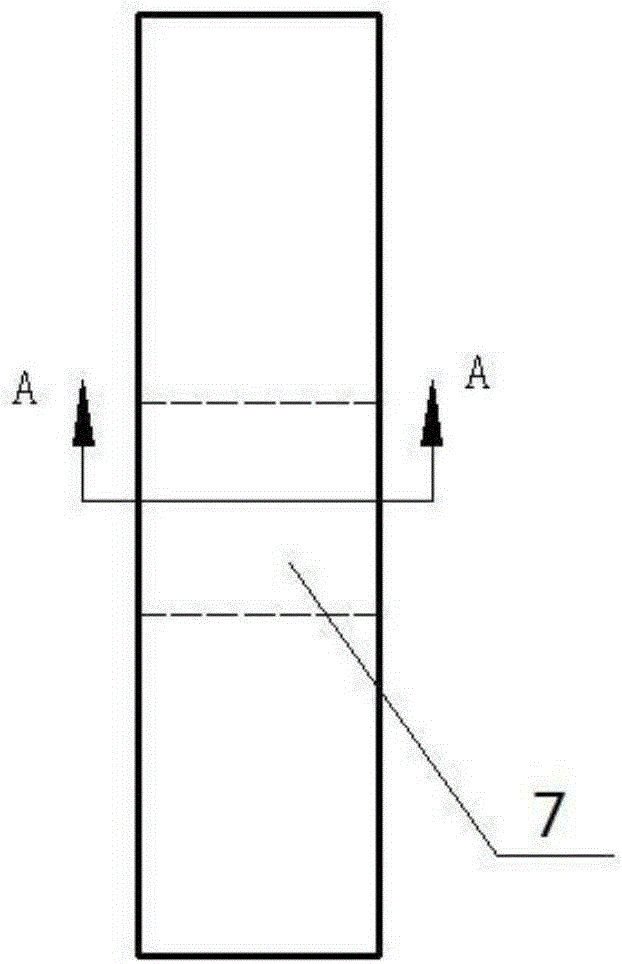

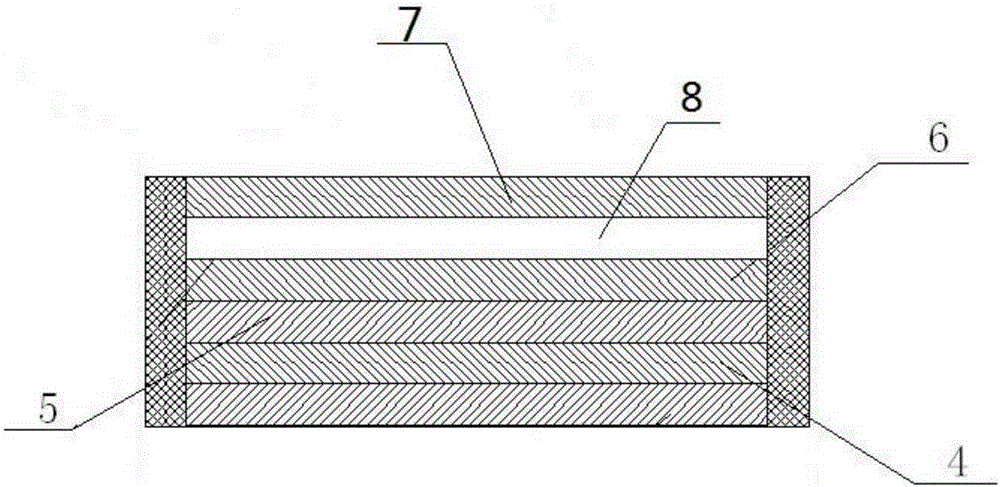

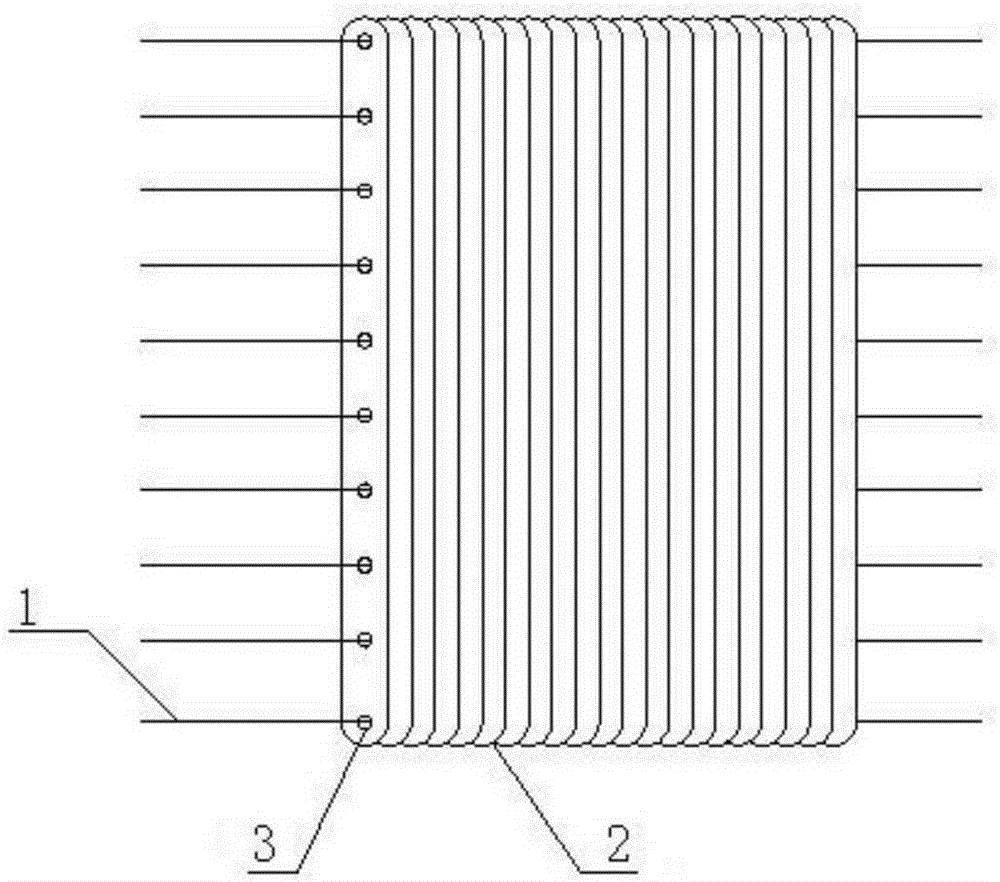

[0015] Such as Figure 1 to Figure 3 As shown, a new type of reinforced tire includes a tire body, a carcass cord 4 and an anti-scratch cloth 7 are provided on the outside of the tire body, and an anti-nail layer 5 is provided between the carcass cord 4 and the anti-scratch cloth 7 and the first reinforcement layer 6, the anti-nail layer 5 includes a plurality of steel sheets 1 and a plurality of steel wires 2, and the plurality of steel sheets 1 are evenly arranged along the axial direction of the tire body, and each steel sheet 2 is provided with A plurality of evenly arranged perforations 3, the same steel wire 2 passes through the perforations 3 at the same position of all steel sheets 1; the first reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com