Silicon-nitrogen-phosphate coordinating flame retardant epoxy resin powder coating suitable for steel tube and preparation method of silicon-nitrogen-phosphate coordinating flame retardant epoxy resin powder coating

A technology of epoxy resin powder and epoxy resin, which is applied in the direction of epoxy resin coatings, powder coatings, fireproof coatings, etc., to achieve the effects of improved flame retardant performance, low cost, and increased thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

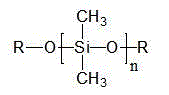

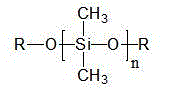

[0055] 1. Preparation of chlorine-terminated polydimethylsiloxane

[0056] Under the protection of nitrogen, add 500mL of toluene, 50g of dihydroxy-terminated polydimethoxysilane, and 5g of dichlorodimethylsilane into a three-necked flask equipped with a condenser, and use lye to absorb hydrogen chloride at the gas outlet, and reflux for 3~ 5h. After the product was washed with water, the solvent was removed in a rotary evaporator, and dried to obtain chlorine-terminated polydimethylsiloxane.

[0057] 2. Preparation of silicon-phosphorus modified epoxy resin base material

[0058] Under nitrogen protection, add 500mL of toluene, 50g of epoxy resin base material BE188 (epoxy equivalent 182-192g / mol), 10g of chlorine-terminated polydimethylsiloxane into a three-necked flask equipped with a condenser, and the gas outlet Absorb hydrogen chloride with lye, use reflux reaction for 3-5 hours, absorb hydrogen chloride produced in the reaction with triethylamine, wash the product wit...

Embodiment 2

[0066] 1. To prepare chlorine-terminated polydimethylsiloxane, the method is the same as in Example 1.

[0067] 2. Preparation of silicon-phosphorus modified epoxy resin base material

[0068] Under nitrogen protection, add 500mL of toluene, 50g of epoxy resin base material BE188 (epoxy equivalent 182-192g / mol), 5g of chlorine-terminated polydimethylsiloxane, 5g of dimethicone into a three-necked flask equipped with a condenser. Chlorodimethylsilane, absorb hydrogen chloride with lye at the gas outlet, use reflux for 3-5 hours, absorb hydrogen chloride produced in the reaction with triethylamine, wash the product with water, remove the solvent in a rotary evaporator, and dry the product for 1-5 hours 3h, after re-dissolving with 500mL toluene, add 10g DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), reflux reaction for 3~5h, wash the product with water, and rotate Remove the solvent in a type evaporator, dry the product for 1-3 hours, and grind it to 100-200 mesh to...

Embodiment 3

[0076] 1. To prepare chlorine-terminated polydimethylsiloxane, the method is the same as in Example 1.

[0077] 2. Preparation of silicon-phosphorus modified epoxy resin base material

[0078] Under the protection of nitrogen, add 500mL of toluene, 80g of epoxy resin base material DER331 (epoxy equivalent 182-192g / mol), 10g of dichlorodimethylsilane into a three-necked flask equipped with a condenser, and absorb the gas outlet with lye Hydrogen chloride, use reflux reaction for 3~5h, absorb the hydrogen chloride produced in the reaction with triethylamine, wash the product with water, remove the solvent in a rotary evaporator, dry the product for 1~3h, re-dissolve with 500mL toluene, add 10g DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), reflux reaction for 3~5h, the product was washed with water and then the solvent was removed in a rotary evaporator, and the product was dried for 1~3h, Grind to 100-200 mesh to prepare silicon-phosphorus modified epoxy resin base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com