Intelligent blocking water-based drilling fluid

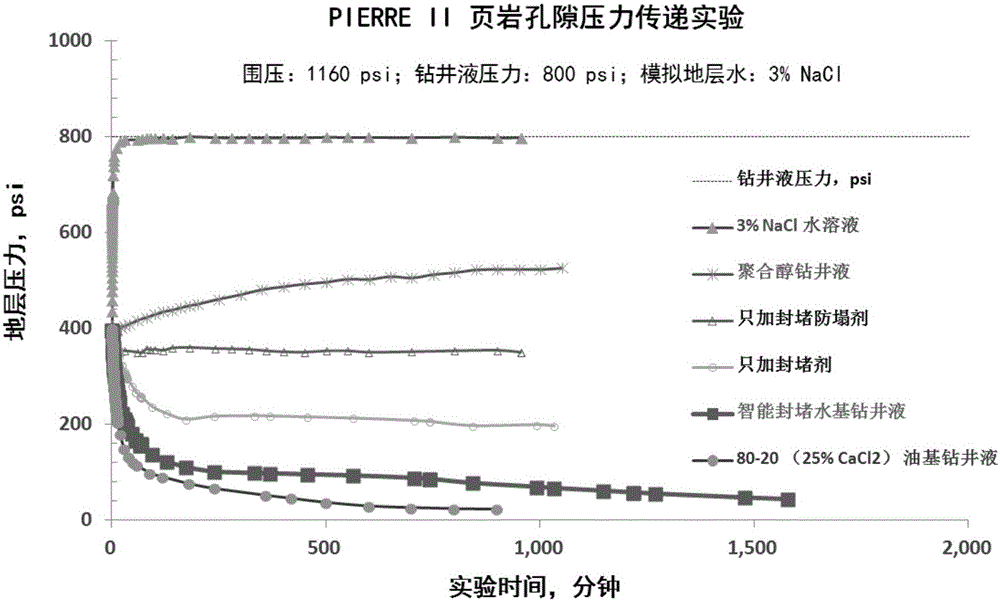

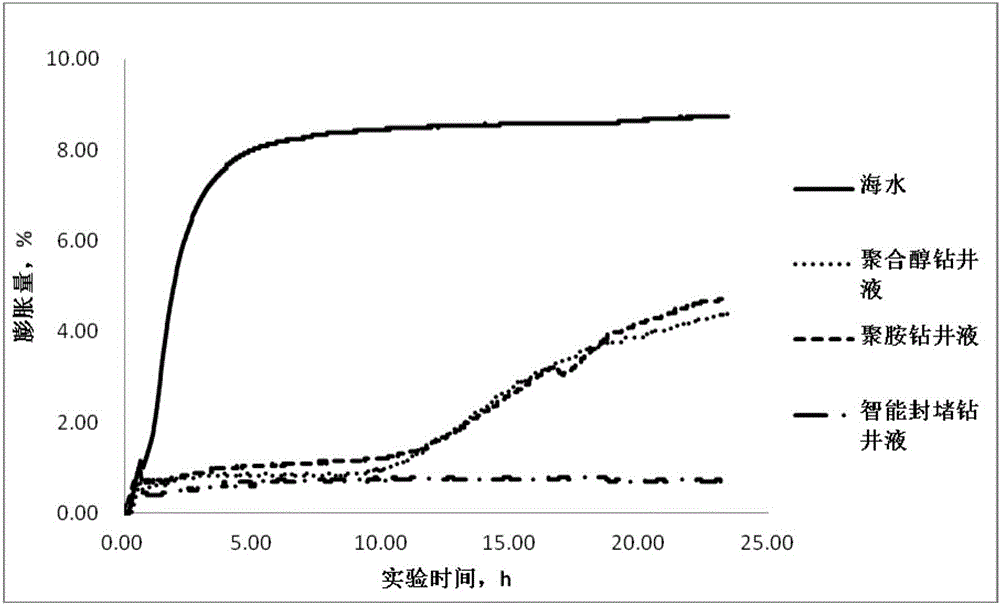

A water-based drilling fluid, intelligent technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high cost of oil-based drilling fluid preparation, limited ability to penetrate deep into mud shale, high risk of environmental pollution, etc., to achieve Inhibit water from entering the interlayer, reduce filtrate intrusion, and improve formation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

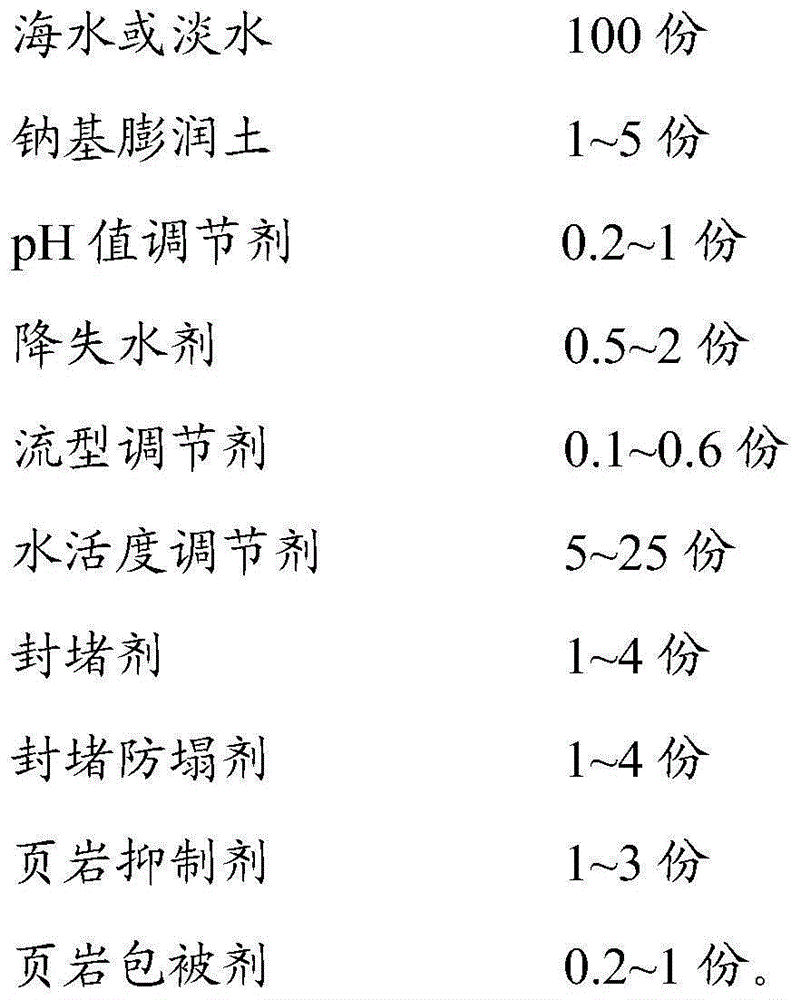

Method used

Image

Examples

Embodiment 1

[0038] Weigh 33g of sodium bentonite slurry with a mass fraction of 12% for at least 16 hours at room temperature, add it into a slurry cup filled with 371g of seawater, and add 0.8g of sodium hydroxide and 2g of polystyrene successively while stirring at a speed of 11000 rpm. Anionic cellulose PAC LV, 0.4g xanthan gum, 20g sodium chloride, 4g plugging agent PF-SmartSeal, 4g plugging and anti-slump agent PF-AquaSeal, 4g shale inhibitor PF-AquaTrol, 0.8g hydrolysis degree 30 % of partially hydrolyzed polyacrylamide, stirred at high speed for 30 minutes.

Embodiment 2

[0040] Weigh 72g of sodium bentonite slurry with a mass fraction of 12% at room temperature for at least 16 hours, add it into a slurry cup filled with 337g of seawater, and add 1.2g of sodium hydroxide and 4g of polyamide successively while stirring at a speed of 11000 rpm. Anionic cellulose PAC LV, 1.2g xanthan gum, 60g sodium chloride, 8g plugging agent PF-SmartSeal, 8g plugging and anti-slump agent PF-AquaSeal, 8g shale inhibitor PF-AquaTrol, 1.6g with a degree of hydrolysis of 30 % of partially hydrolyzed polyacrylamide, stirred at high speed for 30 minutes.

Embodiment 3

[0042] Weigh 100g of sodium bentonite slurry with a mass fraction of 12% for at least 16 hours at room temperature, add it into a slurry cup filled with 312g of seawater, and add 1.2g of sodium hydroxide and 2g of sodium hydroxide successively while stirring at a speed of 11000 rpm. Linked starch, 0.8g xanthan gum, 80g sodium chloride, 12g plugging agent PF-SmartSeal, 12g plugging and anti-slump agent PF-AquaSeal, 12g shale inhibitor PF-AquaTrol, 0.8g part with a hydrolysis degree of 30% Hydrolyze polyacrylamide and stir at high speed for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com