Silver metal oxide inlaid composite strip and preparation method thereof

A composite tape and oxide technology, which is applied in the direction of cable/conductor manufacturing, contacts, electrical components, etc., can solve the problems of low bonding strength, waste of precious metal materials, and cracks on the lateral bonding surface, so as to enhance the effect of atomic diffusion , Improved bonding strength, improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

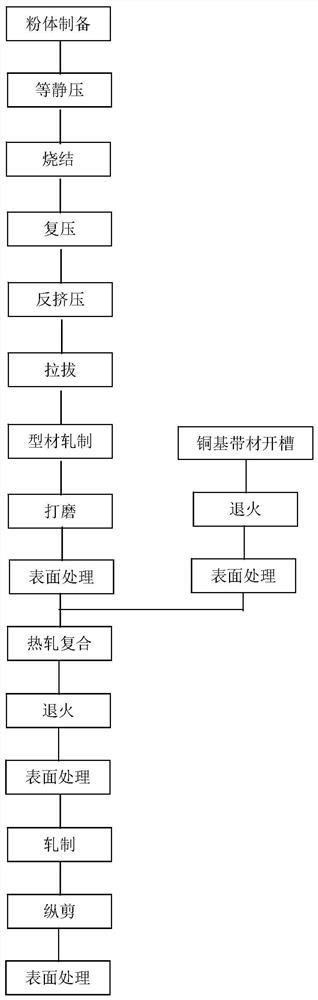

Method used

Image

Examples

Embodiment 1

[0035] a) adopt powder metallurgy process to prepare silver tin oxide powder, adopt atomization process to prepare pure silver powder, tin oxide accounts for 17wt% in the silver tin oxide powder;

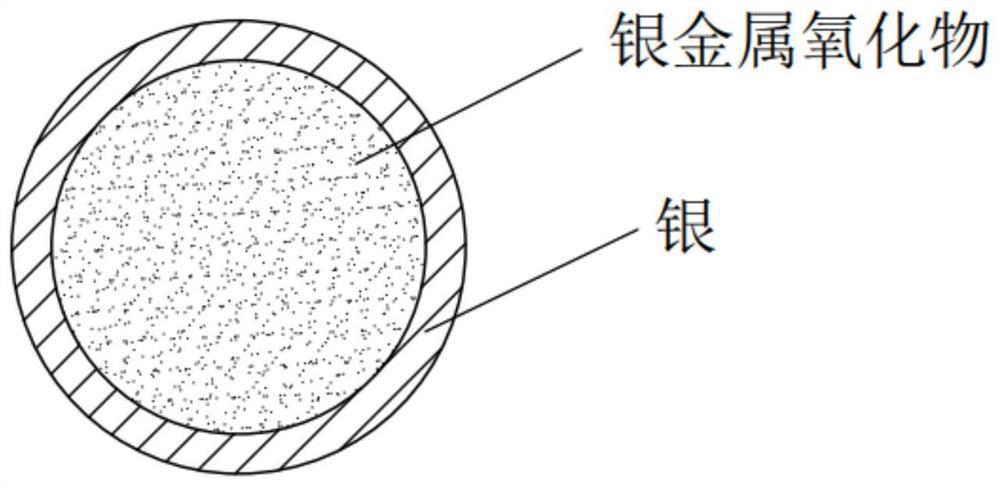

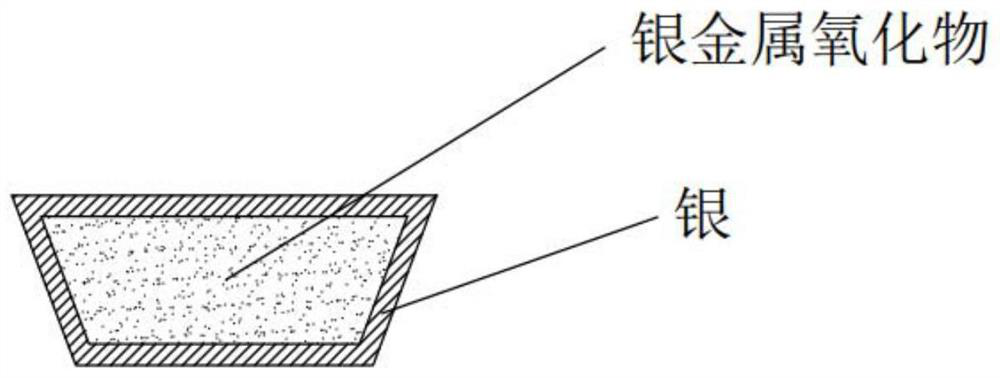

[0036]b) Prepare the rubber sleeve and the metal partition. The cylindrical metal partition is placed inside the rubber sleeve. into the space between the rubber sleeve and the metal partition, pull out the metal partition, and use cold isostatic pressing equipment to press the ingot to obtain a cylindrical coated ingot with a core layer of silver tin oxide and a surface layer of pure silver. The thickness of the pure silver layer in the billet is 5% of the diameter of the entire coated billet;

[0037] c) The coated ingot is sintered in an air atmosphere, the sintering temperature is 930°C, and the sintering time is 4h;

[0038] d) The sintered coated ingot is re-pressed and shaped to obtain a regular and denser coated ingot;

[0039] e) After repressing, the coated ingot is heat...

Embodiment 2

[0047] a) adopt pre-oxidation process to prepare silver tin oxide powder, adopt atomization process to prepare pure silver powder, tin oxide accounts for 10wt% in the silver tin oxide powder;

[0048] b) Prepare the rubber sleeve and the metal partition. The cylindrical metal partition is placed inside the rubber sleeve. into the space between the rubber sleeve and the metal partition, pull out the metal partition, and use cold isostatic pressing equipment to press the ingot to obtain a cylindrical coated ingot with a core layer of silver tin oxide and a surface layer of pure silver. The thickness of the pure silver layer in the billet is 2% of the diameter of the entire coated billet;

[0049] c) The coated ingot is sintered in an air atmosphere, the sintering temperature is 850°C, and the sintering time is 12h;

[0050] d) After sintering, the coated ingot is re-pressed and shaped to obtain a regular and denser coated ingot; e) After re-pressed, the coated ingot is heated a...

Embodiment 3

[0058] a) adopt pre-oxidation process to prepare silver zinc oxide powder, adopt atomization process to prepare pure silver powder, zinc oxide accounts for 15wt% in silver zinc oxide powder;

[0059] b) Prepare the rubber sleeve and the metal partition. The cylindrical metal partition is placed inside the rubber sleeve. into the space between the rubber sleeve and the metal partition, pull out the metal partition, and use cold isostatic pressing equipment to press the ingot to obtain a cylindrical coated ingot with a core layer of silver zinc oxide and a surface layer of pure silver. The thickness of the pure silver layer in the billet is 3% of the diameter of the entire coated billet;

[0060] c) The coated ingot is sintered in an air atmosphere, the sintering temperature is 880°C, and the sintering time is 8h;

[0061] d) After sintering, the coated ingot is re-pressed and shaped to obtain a regular and denser coated ingot; e) After re-pressed, the coated ingot is heated at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com