Patents

Literature

62results about How to "Solve the problem of low bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing cross-linking waterborne adhesive for lithium ion batteries

ActiveCN107793967AIncrease transfer rateConducive to conductionSecondary cellsNegative electrodesWater solubleCurrent collector

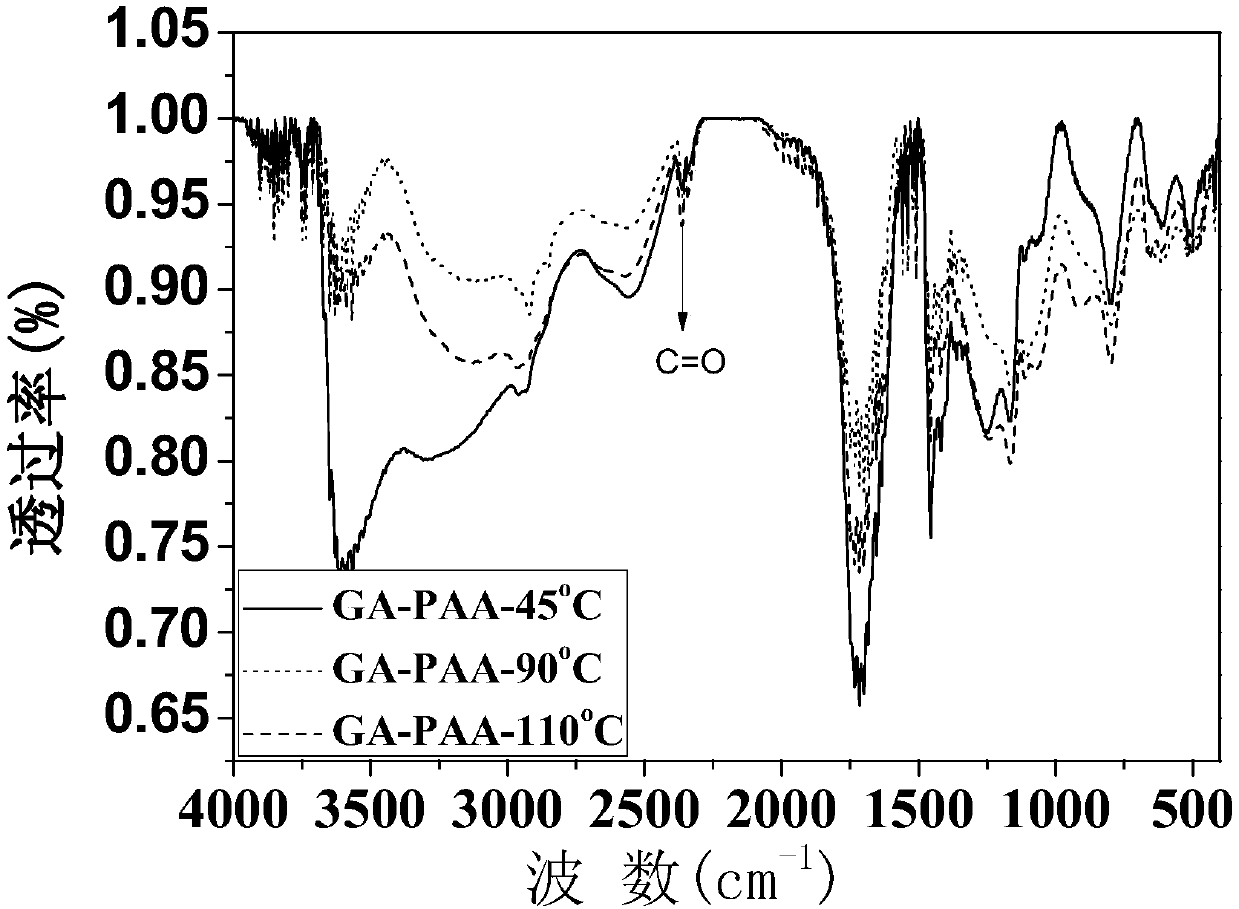

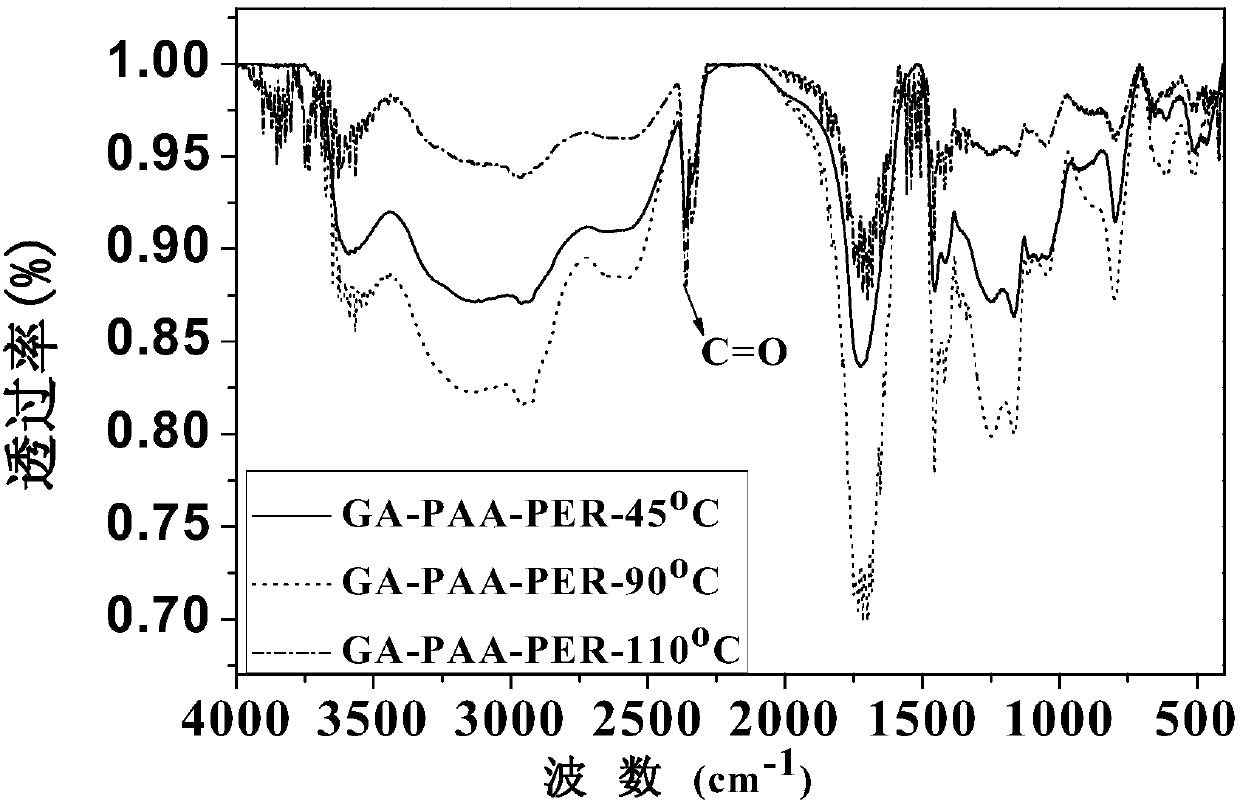

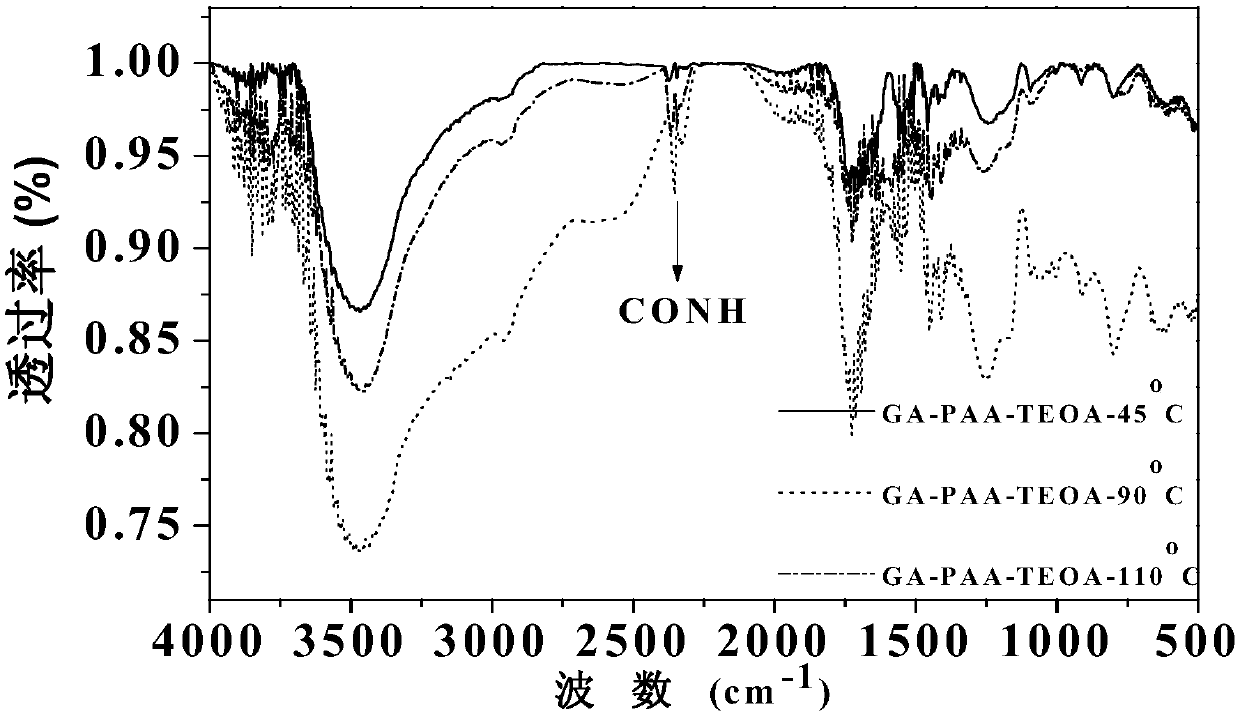

The invention discloses a method for preparing cross-linking waterborne adhesive for lithium ion batteries. Waterborne polymers containing organic carboxylic acid, amino or hydroxyl and a water-soluble micromolecular cross-linking agent containing hydroxyl, amino or carboxyl are jointly used as raw materials of the waterborne adhesive and subjected to cross linking through esterification and amidation under the condition of coating and drying of electrode plate paste of the lithium ion batteries. A preparation process is simple, existing lithium ion battery production process conditions are unchanged, electrodes high in bonding performance, flexibility and elasticity are obtained, and problems of low bonding strength among electrode active substances, conductive agents and current collectors and looseness and shedding due to insufficiency in elasticity for relieving expansion and contraction in charging and discharging processes of the lithium ion batteries in the prior art are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

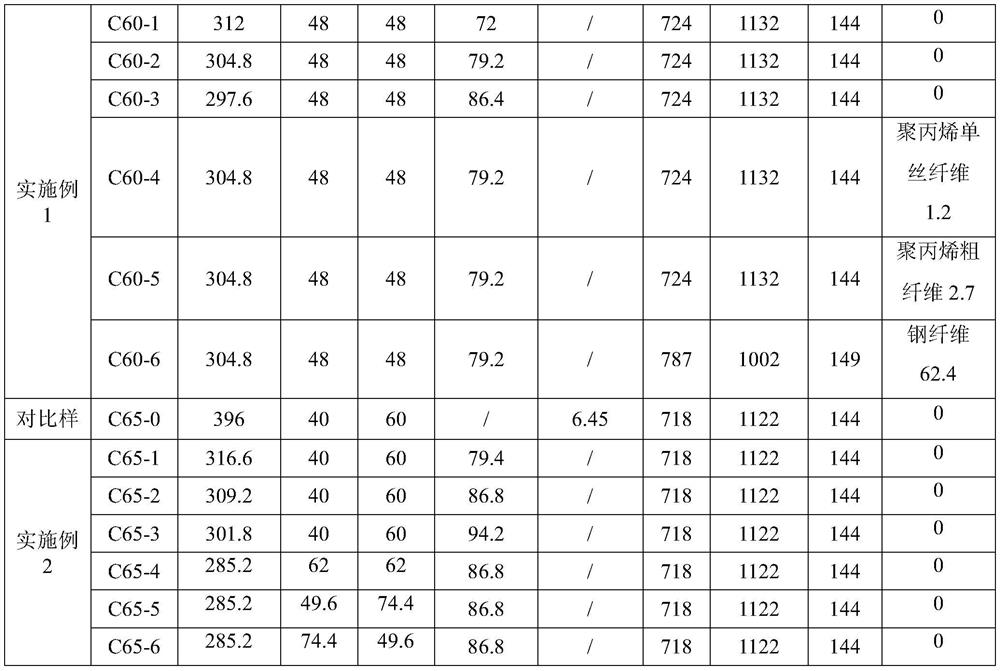

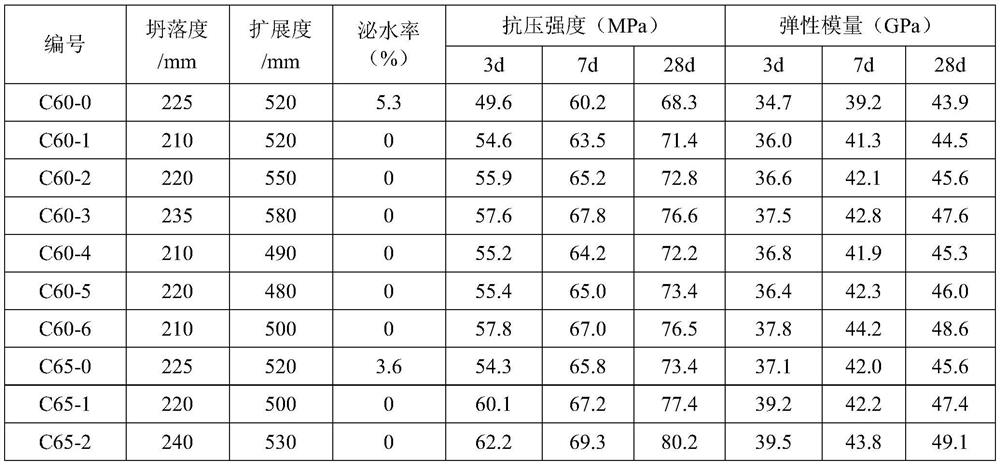

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

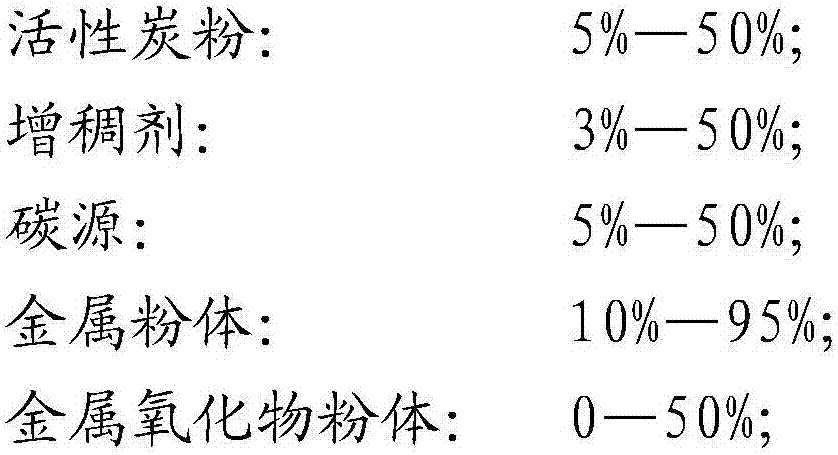

Manufacturing method of copper-aluminum composite board

InactiveCN101559557APrevent oxidationImprove bindingTemperature control deviceTension/compression control deviceCopperAluminum composites

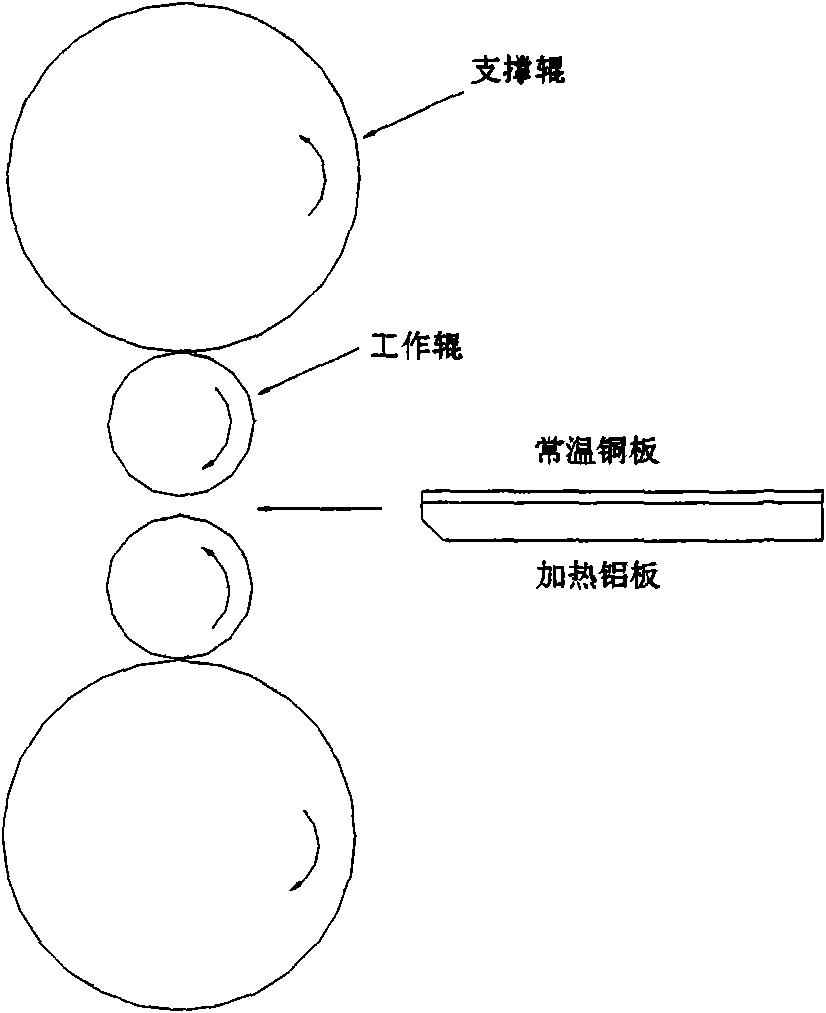

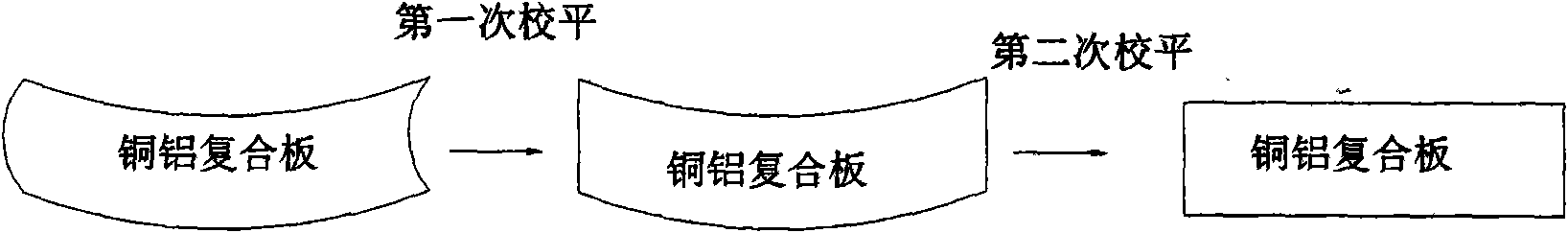

The invention discloses a manufacturing method of a copper-aluminum composite board, comprising the following steps: 1. removing oil for preliminary treatment; 2. grinding a junction surface; 3. heating an aluminum board, not heating a copper board and performing inreversible and isodromic rolling in one pass; 4. adopting a common leveler with fifteen rollers to carry out twice leveling; and 5. cutting to form into finished products. The invention solves the problem that the bonding strength of copper and aluminum is lower and achieves the beneficial effects of producing the high-quality copper-aluminum composite boards in batch with low cost.

Owner:上海新东蒸发器有限公司

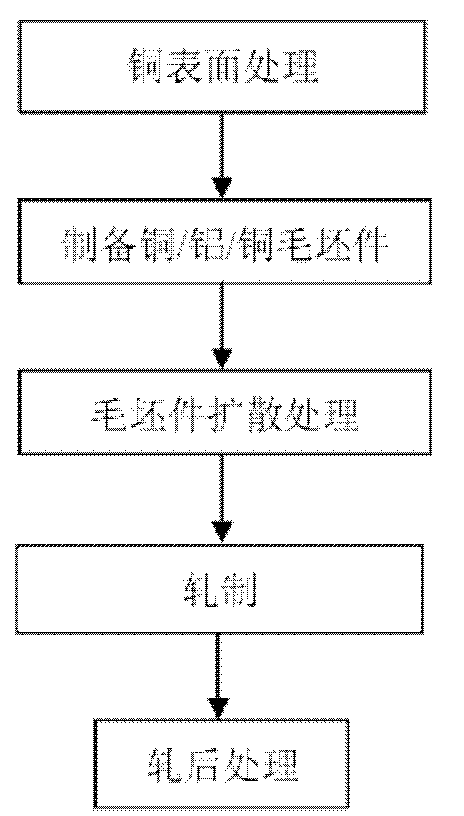

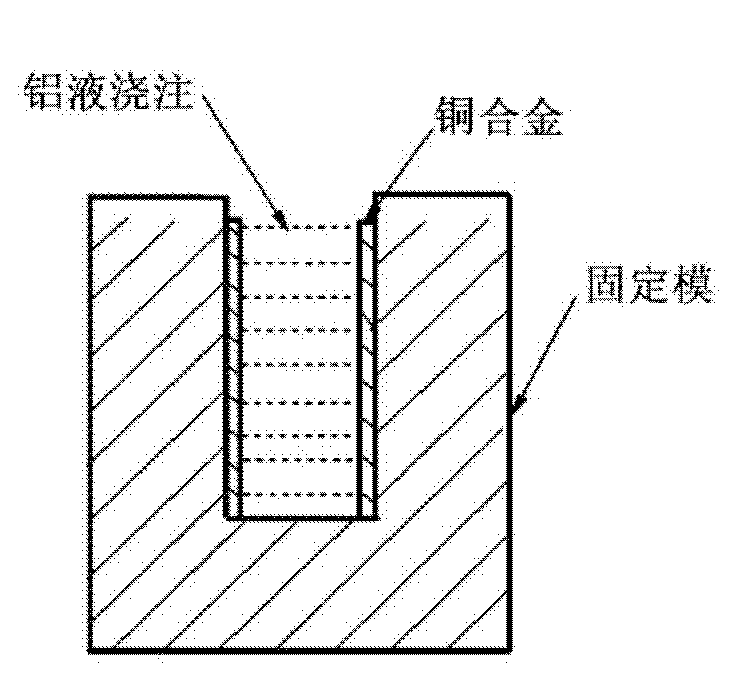

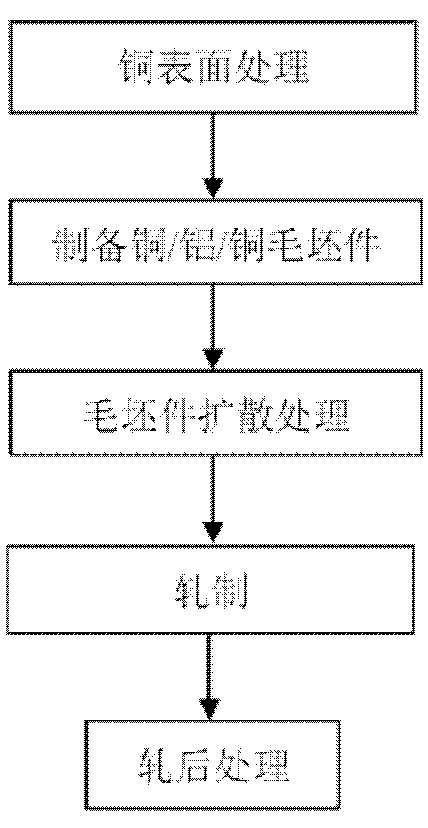

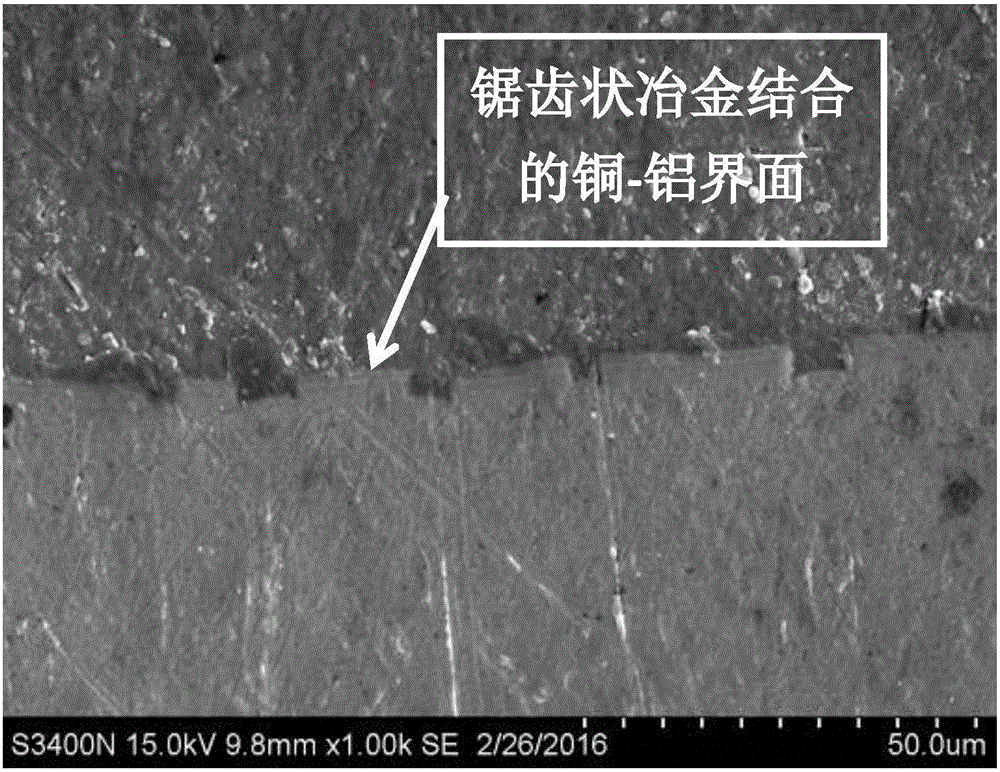

Method for preparing copper-aluminum-copper compound board

InactiveCN102205346ASolve the problem of low bonding strengthHigh bonding strengthAuxillary arrangementsMetal rolling arrangementsButt jointSurface cleaning

The invention belongs to the technical field of compound materials, and discloses a method for preparing a copper-aluminum-copper compound board. The method comprises the following steps of: vertically arranging two copper alloys of which the surfaces are subjected to cleaning pretreatment opposite to each other, pouring the molten aluminum liquid between two copper alloys to obtain an alloy blank, heating the alloy blank, rolling to obtain a copper-aluminum-copper three-layer compound board, and performing post-rolling processing on the copper-aluminum-copper three-layer compound board to obtain the copper-aluminum-copper compound board. The method solves the problems that the bonding strength of a cooper-aluminum interface is low because the surface of copper is easy to oxidize; and by the method, the bonding strength of the cooper-aluminum compound board interface can be improved by about 3 times to the maximum compared with that of the direct plane butt joint rolling method.

Owner:SHANGHAI JIAO TONG UNIV

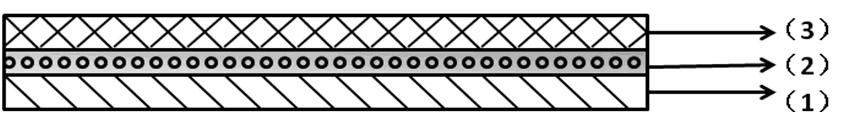

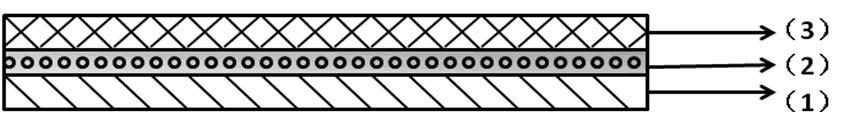

Composite material of high-temperature resistant metal-fabric/resin self-lubricating bearing and preparation method of composite material

InactiveCN102145556AGuaranteed bonding performanceSolve the problem of low bonding strengthSynthetic resin layered productsMetal layered productsPoly ether ether ketoneResin composite

The invention belongs to the technical field of polymer composite materials and in particular relates to a composite material of a high-temperature resistant metal-fabric / resin self-lubricating bearing and a preparation method of the composite material. The composite material comprises three layers, wherein the bottom layer is a metal plate; the middle layer is a porous sintered tin bronze powder layer, and self-lubricating wear-resisting resin is impregnated in a pore; the surface layer is made of the composite material of mixed fabric and self-lubricating wear-resisting resin; the mixed weaved fabric is the composition of at least two materials of polytetrafluoroethylene fiber, carbon fiber, aramid fiber, polybenzimidazole fiber and glass fiber; and the self-lubricating wear-resisting resin is the blend of one or more of polyphenylene sulfide, polytetrafluoroethylene, polyether-ether-ketone and nylon. The composite material of the bearing has good high-temperature resistance, high loading capacity, good wear resistance and good self-lubricating property, solves the problems of high wear rate, poor wear resistance, low-temperature resistance and the like of the material of a DU bearing, and realizes the excellent frictional property and using reliability under high temperature of the material of the bearing. The composite material is applicable to the self-lubricating bearings in the fields of aeronautics and astronautics, machinery, automobiles, home appliances, office facilities and the like.

Owner:FUDAN UNIV

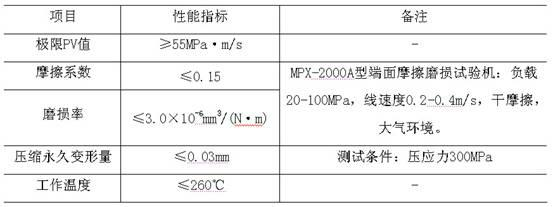

Selective laser melting forming method of multi-material part

InactiveCN111036901ASolve the problem of low bonding strengthQuality improvementAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingProcess engineering

The invention relates to the field of a part forming process, and discloses a selective laser melting forming method of a multi-material part. The method comprises the following steps of S1, part model design, wherein during modeling, materials meeting forming needs are combined to be arranged according to the proper distribution rule, and part model design is finished in an optimized manner; S2,process model obtaining, wherein a designed part model is subjected to size and shape compensation, chamfering, remaining adding, process support design and the like, and a process model is obtained;S3, control file generation, wherein the obtained process model is subjected to layered slicing, the material kind, material distribution and material boundary information contained in each layer areextracted, and a control file guiding an additive manufacturing forming process is generated; S4, additive manufacturing forming; and S5, forming aftertreatment. According to the method, through the selective laser melting forming technology, the high-precision high-quality multi-material part can be formed.

Owner:XIAN SPACE ENGINE CO LTD

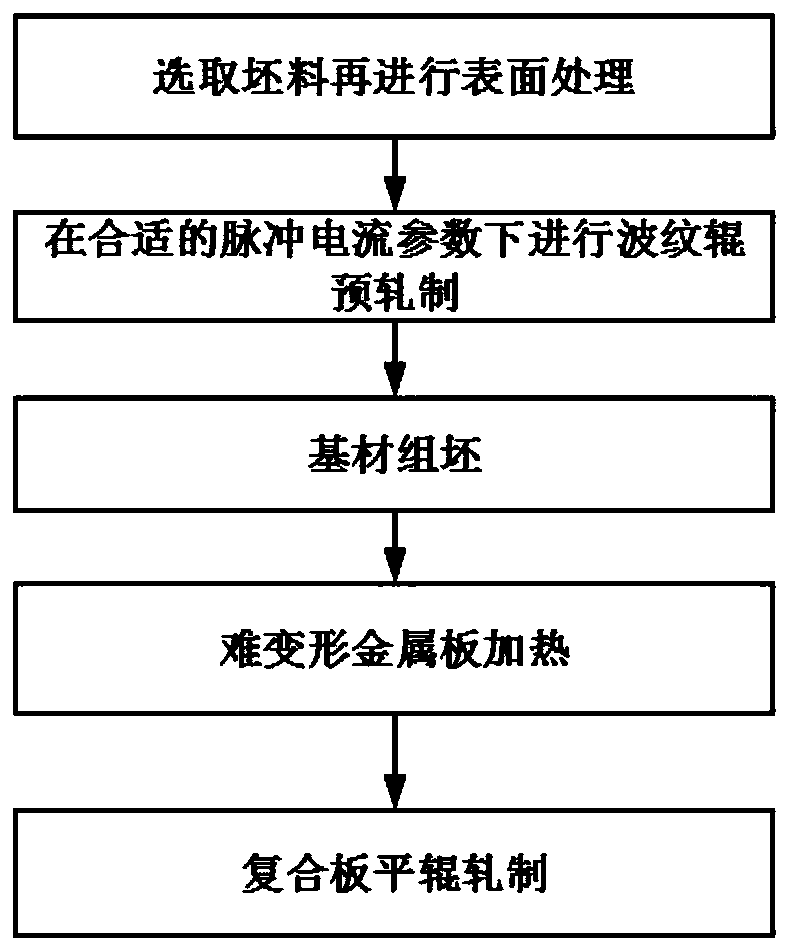

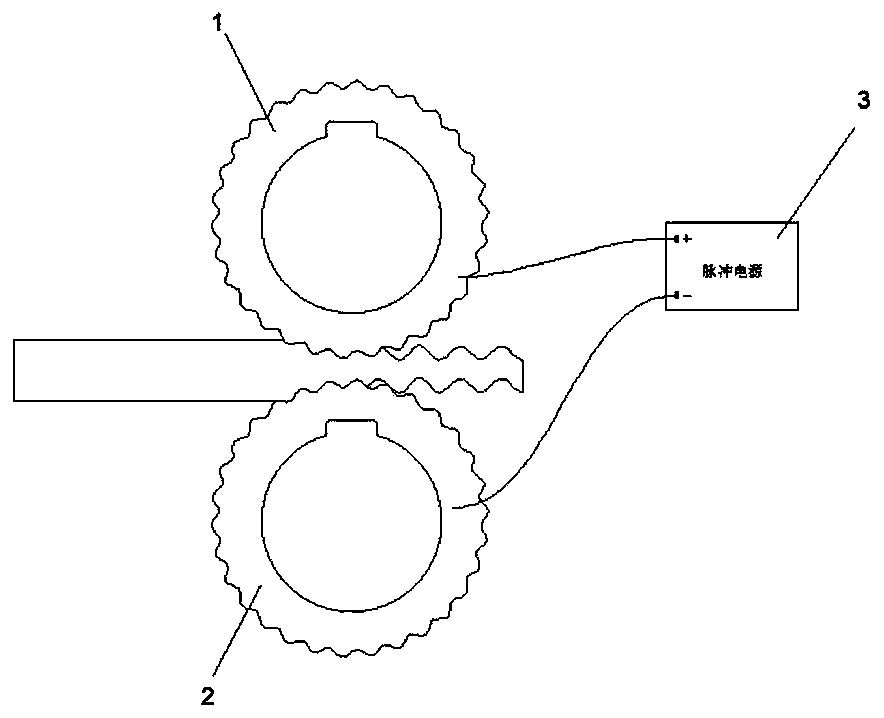

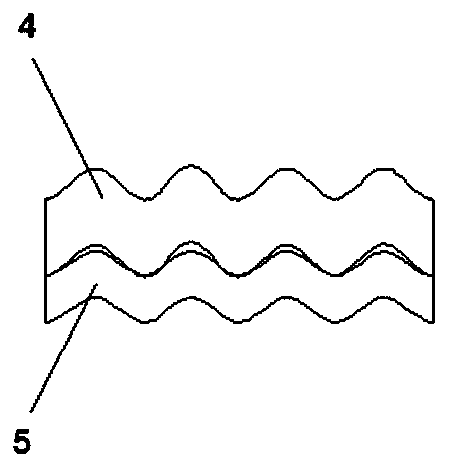

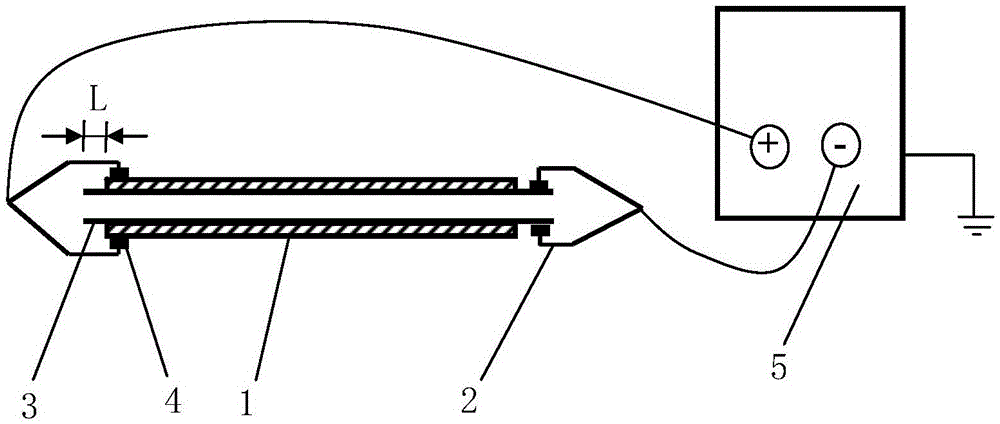

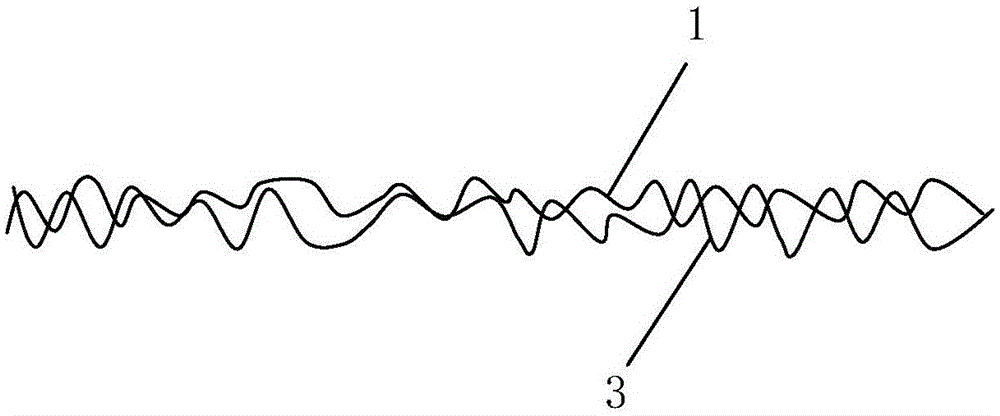

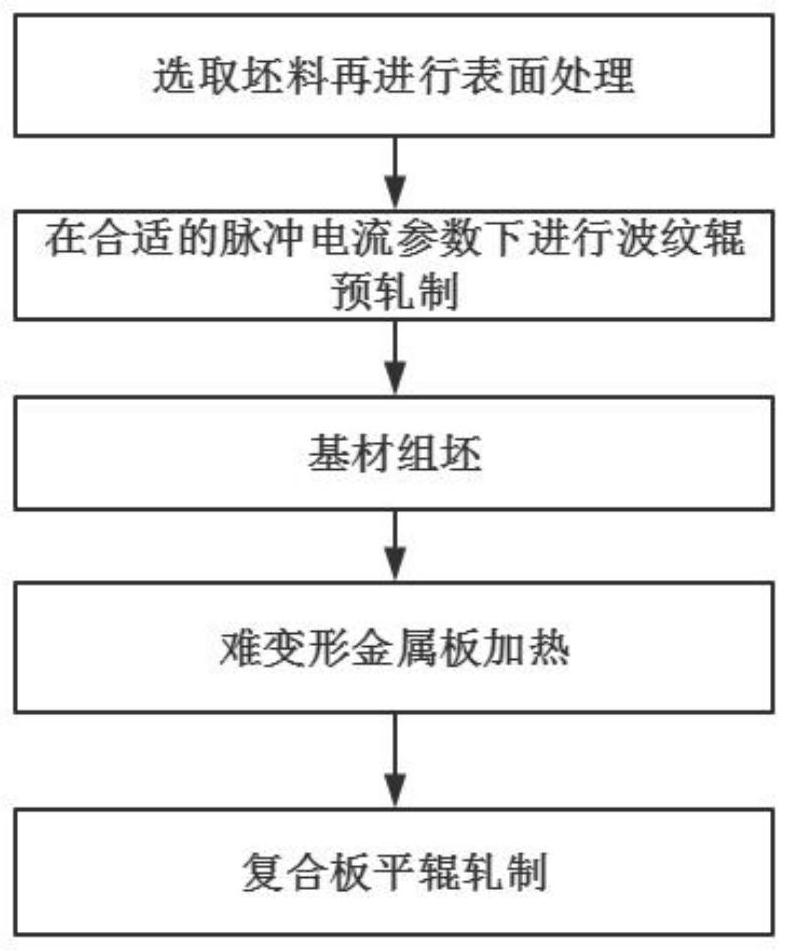

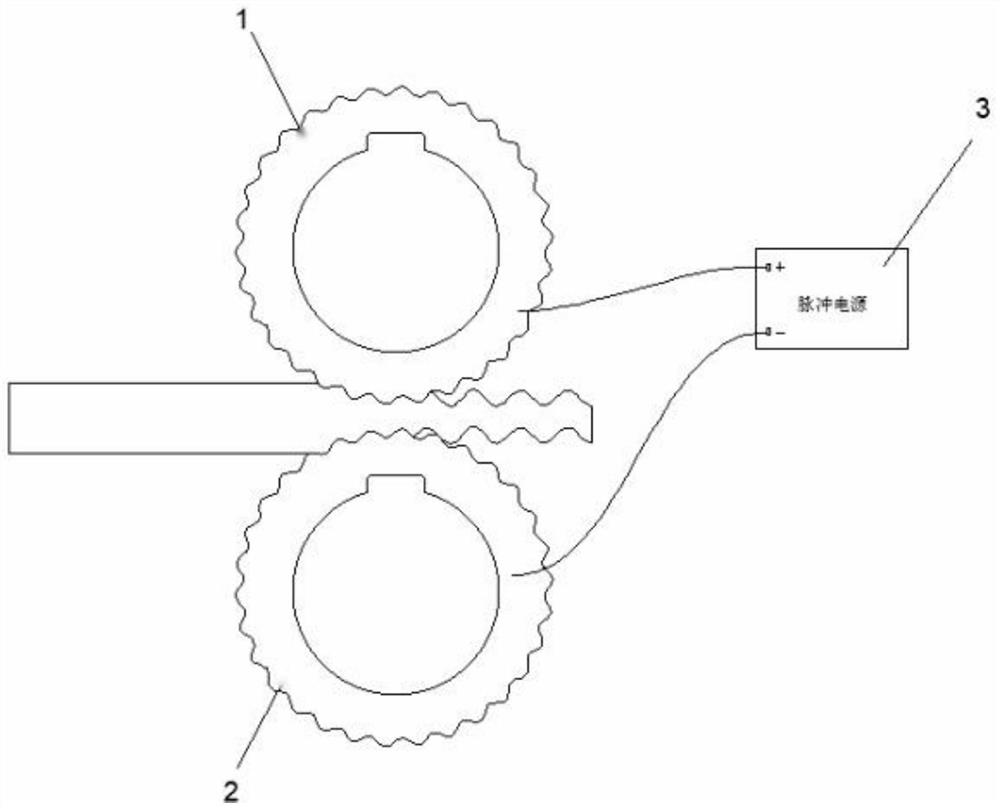

Preparation method of difficult/ easy-to-deform metal composite plate through pulse current auxiliary rolling

ActiveCN111054748ASolve the problem of low bonding strengthReduce deformation resistanceWork heating devicesAuxillary arrangementsComposite platePlastic property

The invention discloses a preparation method of a difficult / easy-to-deform metal composite plate through pulse current auxiliary rolling. The composite plate comprises a difficult-to-deform metal plate and an easy-to-deform metal plate; and after large-ripple pulse current auxiliary pre-rolling and small-ripple pulse current auxiliary pre-rolling are conducted on the difficult-to-deform metal plate and the easy-to-deform metal plate correspondingly, the assembly is put into a rolling mill provided with a pulse power source device to be subjected to flat roller rolling, and the composite plateis obtained. According to the preparation method of the difficult / easy-to-deform metal composite plate through pulse current auxiliary rolling, during rolling, by means of a point discharge effect and an electroplastic effect, the plasticity of the two metal plates is improved, the deformation resistance is reduced, the residual stress is eliminated through discharge in a tiny gap between the metal plates, and therefore metallurgical bonding is achieved. According to the preparation method, the rolling temperature is low, few interface brittle compounds is small, the microstructure is obviously improved, and the prepared material is good in plate shape, high in composite strength and good in interface bonding performance.

Owner:TAIYUAN UNIV OF TECH

Preparation method of copper/graphite film multi-layer laminated blocky composite material

ActiveCN107791616AHigh in-plane thermal conductivityHigh strengthMetal layered productsPolyvinyl butyralElectrolysis

The invention provides a preparation method of a copper / graphite film multi-layer laminated blocky composite material, which can be applied in the field of electronic packaging of an integrated circuit industry. The raw materials of the composite material adopt an anisotropic high-thermal-conductivity net-shaped graphite film and electrolytic pure copper powder. The preparation method comprises the following steps: adding the copper powder into a uniformly mixed solution of an adhesive prepared from polyvinyl butyral and an ethanol solution as well as dimethyl phthalate serving as a plasticizer, completely stirring to obtain uniform slurry with high flowability, spreading the slurry on the net-shaped graphite film uniformly, drying, cutting, degumming, superposing layer by layer, and performing bidirectional pressurizing and sintering to prepare the compact multi-layer laminated blocky composite material with the graphite film and metal copper which are arranged alternately in a layered mode. The heat conductivity of the composite material along the plane direction of the graphite film is 1.5 to 2 times higher than that of pure copper, the density can be reduced to be 65 to 80 percent of the density of the pure copper, and the composite material can be used for replacing the traditional copper tungsten metal heat-conducting material.

Owner:UNIV OF SCI & TECH BEIJING

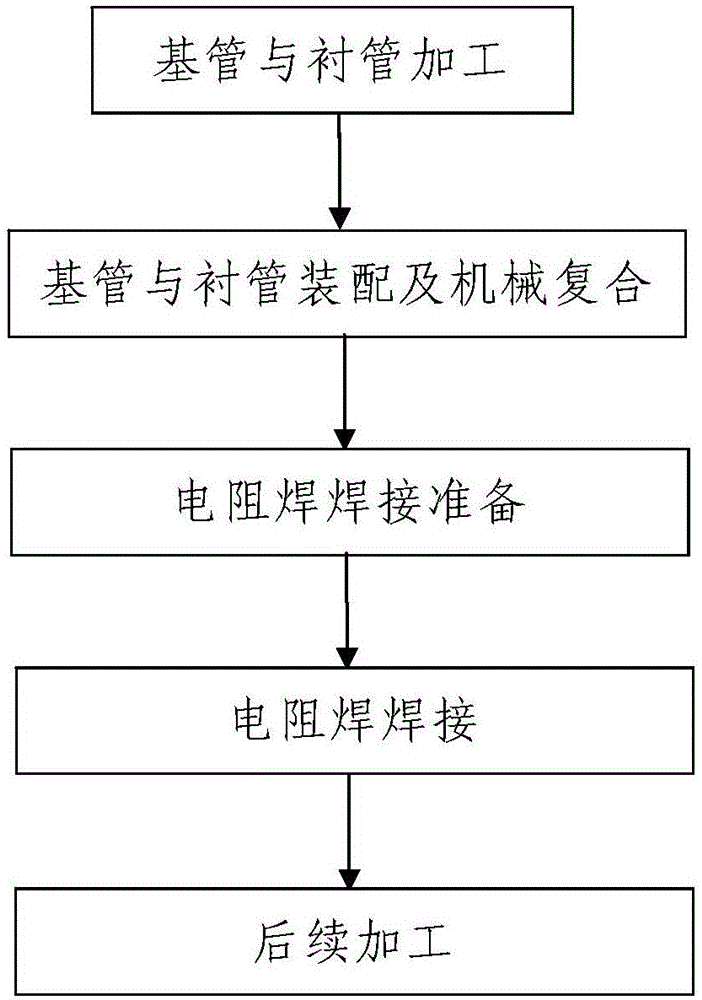

Method for producing semi-metallurgical metal composite tube through electric resistance welding

ActiveCN105081541AThe method steps are simpleReasonable designMetal working apparatusTubular articlesElectrical resistance and conductanceEngineering

The invention discloses a method for producing a semi-metallurgical metal composite tube through electric resistance welding. The method includes the steps that firstly, a base tube and a liner tube are machined; secondly, the base tube and the liner tube are assembled and mechanically composited to form a mechanical metal composite tube; thirdly, welding preparation of electric resistance welding is conducted, two electric resistance welding electrodes of an electric resistance welding machine are installed at the two ends of the mechanical metal composite tube respectively, one electric resistance welding electrode is installed on the extending section at one end of the liner tube, and the other electric resistance welding electrode is installed at one end of the base tube; fourthly, electric resistance welding is conducted, the base tube and the liner tube in the mechanical metal composite tube are welded through the electric resistance welding machine; and fifthly, subsequent machining is carried out. The method is simple in step, reasonable in design, convenient to implement, high in welding quality and good in use effect. Bonding strength between the base tube and the liner tube in the machined and formed semi-metallurgical metal composite tube is high. Besides, machining efficiency is high, and machining quality is easy to guarantee.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Nanometer heat insulation paint and preparation method thereof

InactiveCN108264813ASolve the problem of low bond strengthStrong adhesionFireproof paintsCelluloseTin dioxide

The invention discloses nanometer heat insulation paint and a preparation method thereof. The nanometer heat insulation paint is mainly prepared from the following raw materials in parts by weight: 30to 40 parts of silicone acrylic emulsion, 6 to 10 parts of ceramic microbeads, 5 to 10 parts of silica gel, 14 to 20 parts of titanium dioxide, 1.5 to 2 parts of carbon nanometer tubes, 2 to 6 partsof nanometer tin dioxide, 3 to 5 parts of nanometer zirconium oxide, 8 to 12 parts of quartz powder, 0.4 to 0.8 part of cellulose thickening agents, 0.4 to 0.7 part of dispersing agents, 0.2 to 0.6 part of anti-foaming agents, 0.3 to 0.5 part of leveling agents, 1.3 to 1.7 parts of coalescing agents and 22 to 26 parts of deionized water. The nanometer heat insulation paint can effectively solve the problem of low bonding strength of the paint on a wall body, and has the advantages of good heat insulation effect, short curing time, strong adhesive force, long service life and the like.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

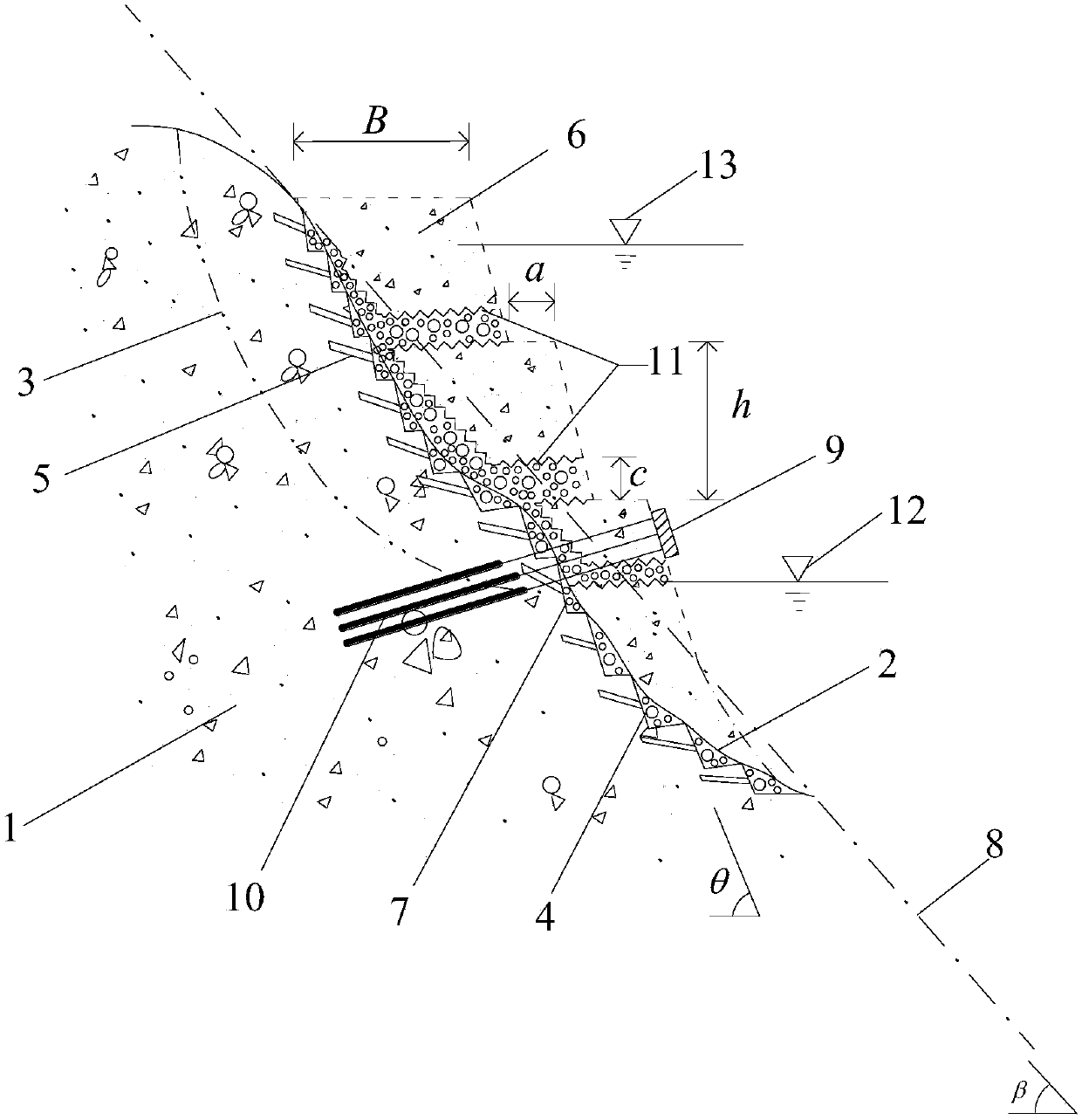

Coastal reservoir land reclamation type bank protection structure and construction method thereof

ActiveCN107761668ASolve the problem of synchronous drainageReduce adverse effectsCoastlines protectionLand resourcesStructure of the Earth

The invention provides a coastal reservoir land reclamation type bank protection structure. The coastal reservoir land reclamation type bank protection structure comprises earth-filled interface steps, water-permeable earth-filled layers and water-impermeable earth-filled layers, wherein the earth-filled interface steps are arranged along a bank protection foundation slope surface; each water-permeable earth-filled layer is arranged on the corresponding earth-filled interface step in a covering manner; and each water-impermeable earth-filled layer is arranged on the corresponding water-permeable earth-filled layer in a covering manner. The water-impermeable earth-filled layers are arranged into a multi-level step structure along the bank protection foundation slope surface from bottom to top. A water-permeable earth-filled layer is also arranged at the whole bottom of the water-impermeable earth-filled layer step at each level. Anti-seepage geotechnical cloth is arranged between each water-permeable earth-filled layer and the corresponding water-impermeable earth-filled layer. The water-permeable earth-filled layers are formed by being filled with sand gravel. The water-impermeableearth-filled layers are formed by being filled with a viscous soil body in a layered manner. By means of the coastal reservoir land reclamation type bank protection structure, the land-filled structure which guarantees stability of a coastal reservoir bank slope and meanwhile newly increases land is formed; the geological environment of a coastal reservoir region is effectively protected; and exploitation and utilization of bank slope land resources are promoted.

Owner:CHINA THREE GORGES UNIV +4

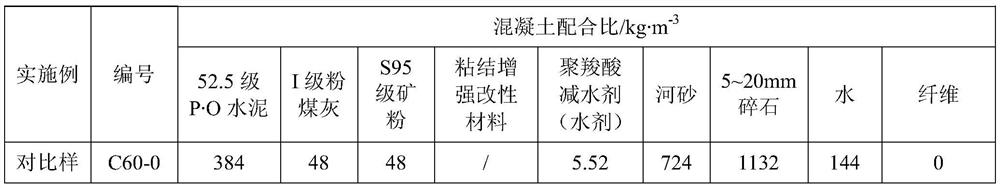

Bonding reinforced modified material and application thereof in wet joint concrete of steel-concrete composite bridge deck

PendingCN111892329AImprove liquidityGuaranteed construction effectSolid waste managementBridge structural detailsBridge deckUltimate tensile strength

The invention relates to a bonding reinforced modified material and an application thereof in wet joint concrete of a steel-concrete composite bridge deck. The bonding reinforced modified material iscomposed of the following components in percentage by mass: 55 to 70 percent of an expansion component, 20 to 35 percent of silica fume, 0 to 2.5 percent of an early strength component, 1.8 to 5 percent of a tackifying and toughening component, 1 to 3 percent of a water reducing component, 0.5 to 2.0 percent of a shrinkage reducing component, 0 to 0.25 percent of a tackifying and water retaining component and 0 to 1 percent of a defoaming agent. The bonding reinforced modified material provided by the invention solves the problems of cracking of wet joint concrete, cracking of new and old concrete interfaces, large early tension creep and low bonding strength of new and old concrete, and is suitable for wet joint engineering with high requirements on bonding and shrinkage creep propertiesof new and old concrete interfaces.

Owner:HUBEI CHANGJIANG ROAD & BRIDGE HLDG

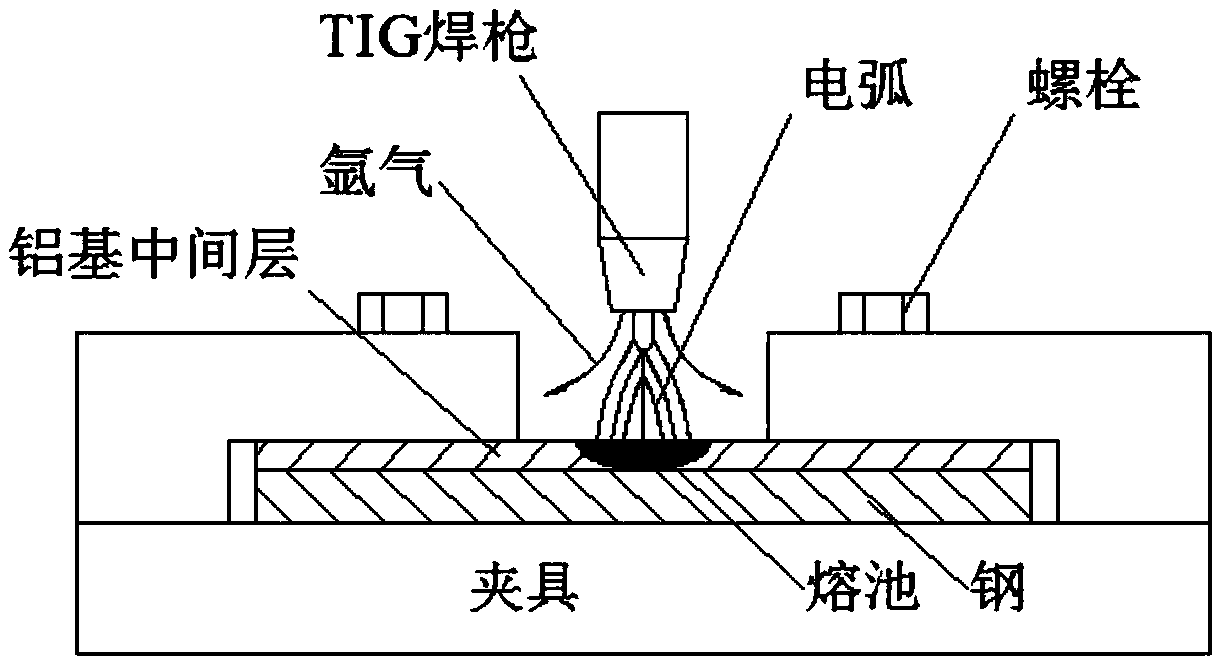

Method of micro-arc oxidation for steel surface

InactiveCN108193246ABeautiful weld shapeHigh bonding strengthAnodisationArc welding apparatusMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a method of micro-arc oxidation for steel surface. The steel surface can obtain a compact ceramic layer through the method of micro-arc oxidation for the steel surface, and the method of micro-arc oxidation for the steel surface can be used for improving the anti-corrosion performance of steel. A layer of aluminum with high bonding strength is firstly welded to the surfaceof a steel substrate in an aluminum steel melting-braze welding method, then the ceramic layer is obtained through a micro-arc oxidation technology, the problem of low bonding strength of the ceramiclayer on the steel substrate is solved on the one hand, and the anti-corrosion performance of the steel can be improved on the other hand.

Owner:JIANGSU UNIV

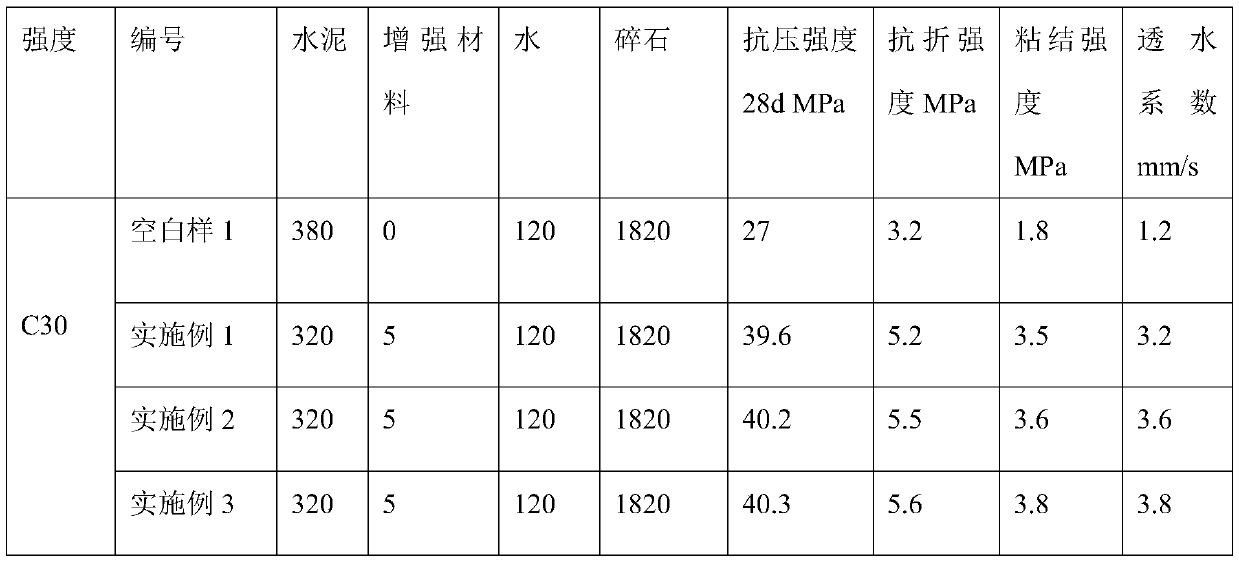

A water-based liquid reinforcing material for high-performance water-permeable concrete and a preparation method thereof

A water-based liquid reinforcing material for high-performance water-permeable concrete is disclosed. Raw materials of the water-based liquid reinforcing material include, by weight, 5-20 parts of powder reinforcing polymer, 35-50 parts of nanometer silica fume, 10-20 parts of a water reducing agent, 3-5 parts of a viscosity adjusting agent, 0.2-2 parts of a defoamer, 0.1-2 parts of a retarder, 0.5-1 part of a rheological agent and 10-15 parts of an early strength agent. A preparation method of the water-based liquid reinforcing material is also disclosed.

Owner:四川珠峰飞越科技有限责任公司

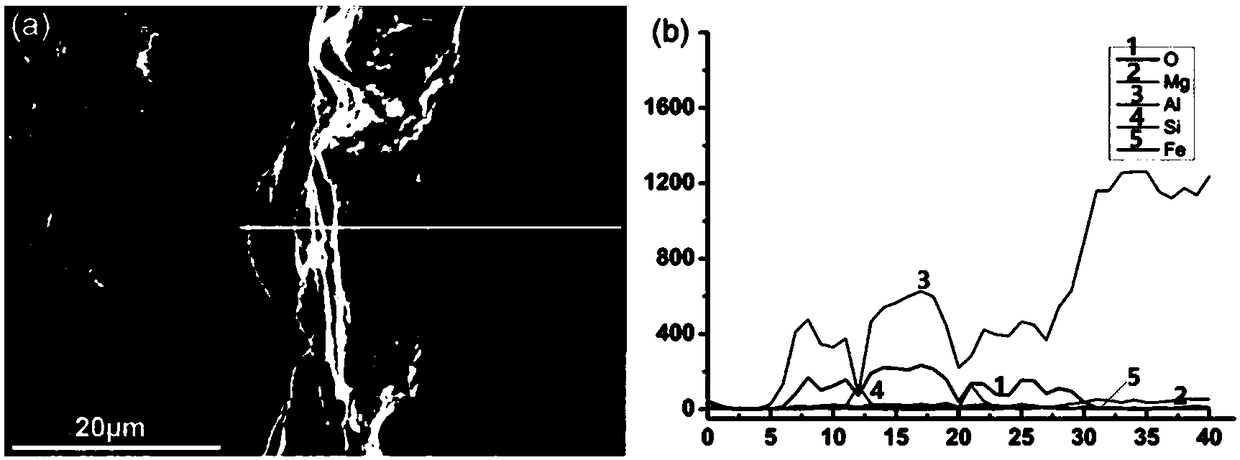

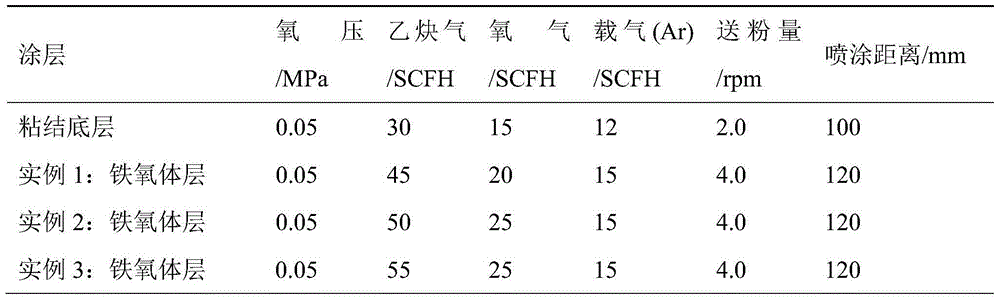

Method for preparing lithium ferrite anticorrosive coatings by flame spraying

ActiveCN103981477AHigh bonding strengthAccelerated corrosionMolten spray coatingConductive coatingOxygen

The invention relates to a method for preparing lithium ferrite anticorrosive coatings by flame spraying. Lithium ferrite conductive anticorrosive coating materials, prepared by adopting a manipulator through optimizing the technological parameters of oxygen-acetylene flame spraying, have excellent corrosion resistance and conductivity. The preparation method, provided by the invention, has the advantages of simple process, high deposition rate, strong repeatability and low facility request, can directly implement the spraying construction on site so as to meet the construction and repair requirements of actual grounding network engineering, and can be applied to metallic matrix surfaces with different shapes or different sizes; in particular, the preparation method has more advantages when preparing large-area anticorrosive conductive coatings for practical application; and meanwhile, the maintenance is simple in the workpiece service process, so that the preparation method is suitable for industrial popularization and application.

Owner:STATE GRID CORP OF CHINA +1

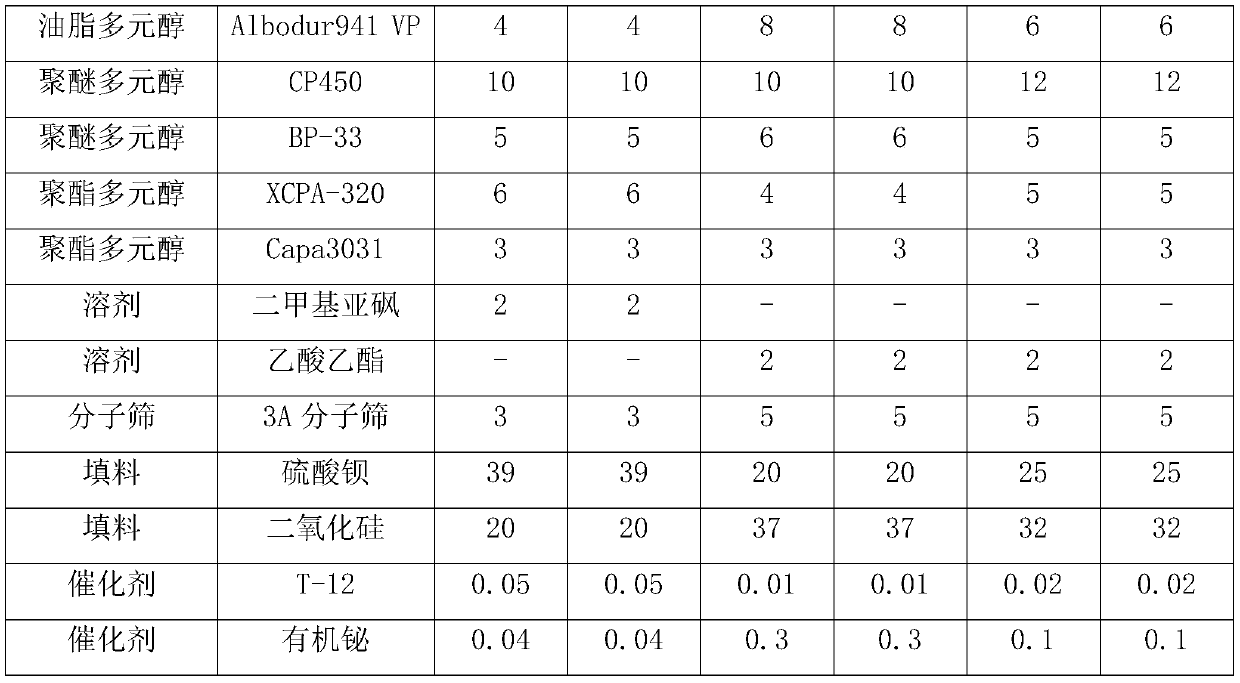

Polyurethane structural adhesive as well as preparation method and application thereof

ActiveCN111320959AHigh bonding strengthImprove stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCyclohexanonePolyester

The invention relates to the field of chemical engineering, and particularly discloses a polyurethane structural adhesive and a preparation method and application thereof, the polyurethane structuraladhesive comprises a component A and a component B, and the component B is a curing agent; wherein the component A comprises the following raw materials: grease polyol, polyether polyol, polyester polyol, a solvent, a molecular sieve, a filler and a catalyst; wherein the solvent is selected from any one or more of dimethylformamide, dimethyl sulfoxide, ethyl acetate or cyclohexanone. The preparedpolyurethane structural adhesive is high in bonding strength, by adding a small amount of solvent into the component A, an SMC composite material base material does not need to be treated at all before the adhesive is used, and the problems that an existing adhesive needs to treat the surface of an SMC composite material before bonding to achieve effective bonding and is low in bonding strength are solved; the preparation method provided by the invention is simple, and the prepared polyurethane structural adhesive is high in curing rate after sizing, so that the production efficiency is greatly improved.

Owner:上海汉司实业有限公司

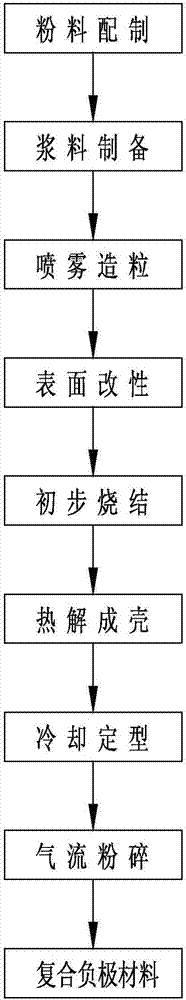

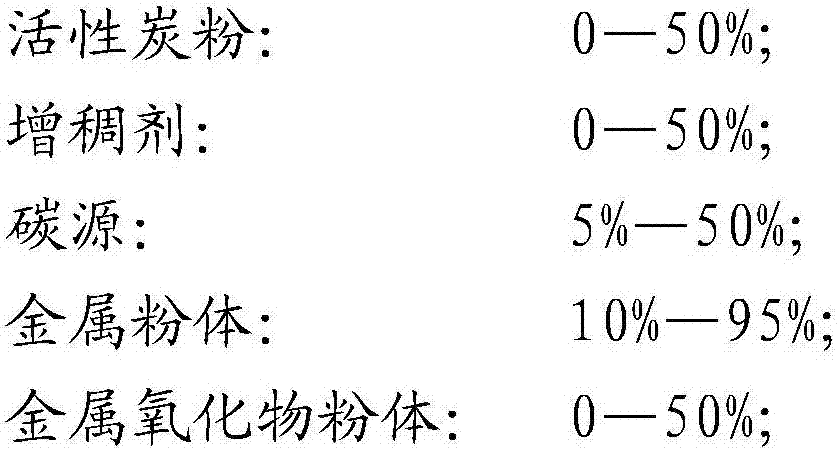

Production technology for composite material consisting of metal and oxides thereof and carbon

InactiveCN106876678AReduce peelingImprove performanceElectrode thermal treatmentNegative electrodesCarbon compositesPolyvinyl alcohol

The invention discloses a production technology for a composite material consisting of metal and oxides thereof and carbon. The production technology comprises powder material preparation, slurry preparation, spray granulation, surface modification, preliminary sintering, pyrolysis shell-forming, cooling sizing, airflow crushing, and compounding of negative electrode material; a carbon source comprises the mixture of any one or two or more of cane sugar, polyvinyl alcohol and starch high polymer material; metal powder comprises the mixture of any one or two or more of stannum, zinc and aluminum metal materials; metal oxide powder comprises the mixture of any one or two or more of stannum oxide, zinc oxide and aluminum oxide powder; sodium carboxymethyl cellulose is used as a thickener. According to the production technology provided by the invention, the carbon source, and the metal stannum, zinc and aluminum and the oxides thereof are subjected to coating treatment to prepare a composite negative electrode material with a spherical core-shell structure, expansion of a metal core negative electrode is limited and stripping of the metal negative electrode and foil is effectively relieved by pyrolyzing a carbon shell.

Owner:江苏强劲新能源科技有限公司

Zirconium nitride aluminum/aluminium oxide composite coating firmly combined with hard alloy and preparation method thereof

ActiveCN110656313AImprove bindingSolve the problem of low bond strengthVacuum evaporation coatingSputtering coatingEtchingHigh entropy alloys

The invention discloses a zirconium nitride aluminum / aluminium oxide composite coating firmly combined with a hard alloy. The zirconium nitride aluminum / aluminium oxide composite coating is a whole composed of five sublayers of a CoNiCrAlY high entropy alloy bonding layer, an alpha-Cr2O3 oxide template layer, an alpha-Al2O3 oxide supporting layer, a AlZrON nitric oxide cohesion layer and a AlZrN nitride wearing layer, wherein the five sublayers are arranged from the inside to outside in sequence, and the total thickness of the coating is 1-2.5 microns. A preparation method of the coating comprises the following steps that after a hard alloy substrate is heated and subjected to ion etching, firstly, a CoNiCrAlY layer is deposited on the substrate by using an electric arc evaporation platingprocess, and then the alpha-Cr2O3 layer, the alpha-Al2O3 layer, the AlZrON layer, and the AlZrN layer are sequentially deposited by using a magnetron sputtering process. The high entropy alloy bonding layer is adopted, different functional sub-layers cooperate with one another, so that the bonding between the coating and the hard alloy substrate is firm, the comprehensive performance of the coating is excellent, the process is simple, and the implementation is easy.

Owner:SICHUAN UNIV

Hole-type rolling forming method for metal layered composite plate

ActiveCN111922077ASolving Aluminum Spill ProblemsSolve coordination problemsAuxillary arrangementsMetal rolling arrangementsComposite plateUltimate tensile strength

The invention discloses a hole-type rolling forming method for a metal layered composite plate. The hole-type rolling forming method comprises the following steps: fixing a to-be-compounded steel plate and a to-be-compounded aluminum plate to form a steel / aluminum assembled plate blank; performing cold rolling by utilizing a hole-type cold rolling mill to prepare a steel / aluminum layered composite plate; and preparing a to-be-compounded aluminum alloy plate, processing the steel / aluminum layered composite plate and the to-be-compounded aluminum alloy plate, aligning and stacking according toa sequence of aluminum alloy / aluminum / steel / aluminum alloy, fixing to form an aluminum alloy / aluminum / steel / aluminum alloy assembled plate blank, heating to a preset temperature, rolling by utilizing a hole-type hot rolling mill to prepare an aluminum alloy / aluminum / steel / aluminum alloy layered composite plate, and separating from a steel-steel interface to obtain an aluminum alloy / aluminum / steel layered composite plate. The hole-type rolling forming method effectively solves the problems that component metal is not coordinated in deformation, the interface is easily oxidized and the bonding strength is low in a rolling process of the steel / aluminum alloy layered composite plate, and realizes continuous preparation of the steel / aluminum alloy layered composite plate with highinterface bonding strength and stable performance.

Owner:TAIYUAN UNIV OF TECH

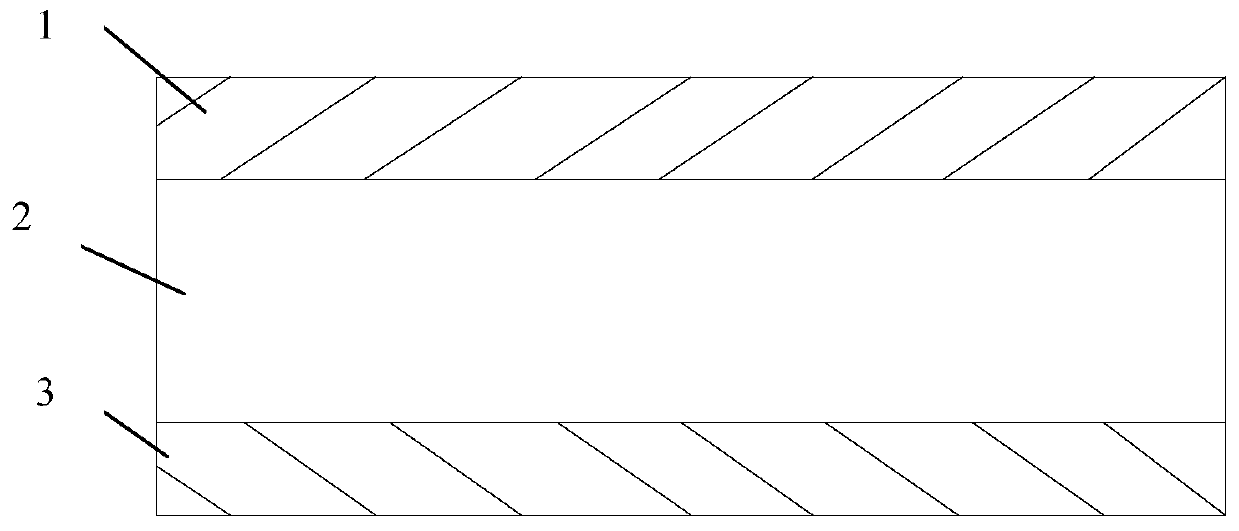

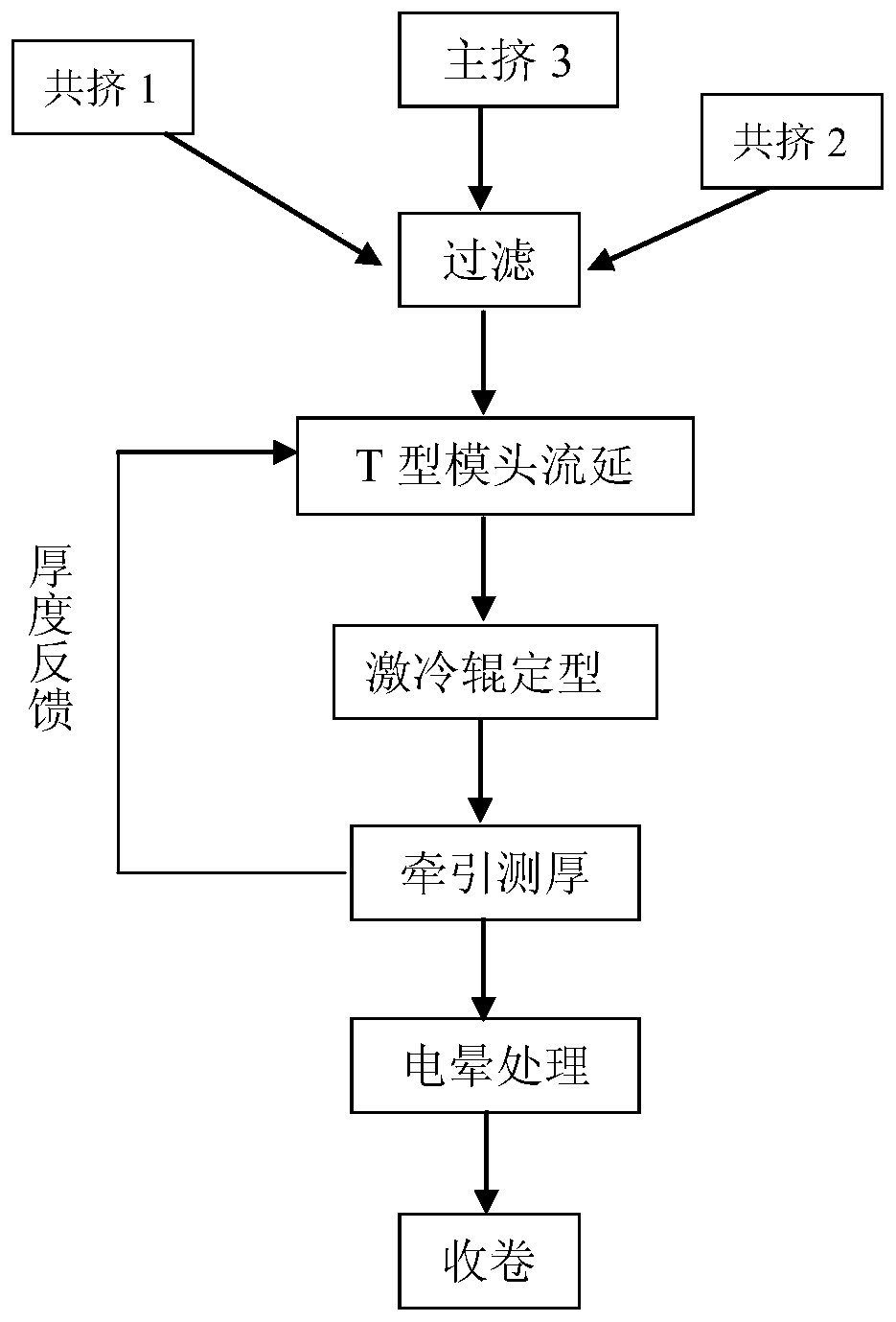

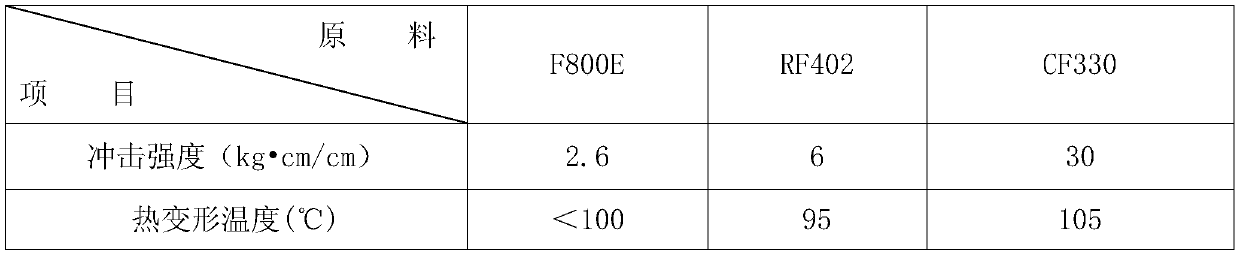

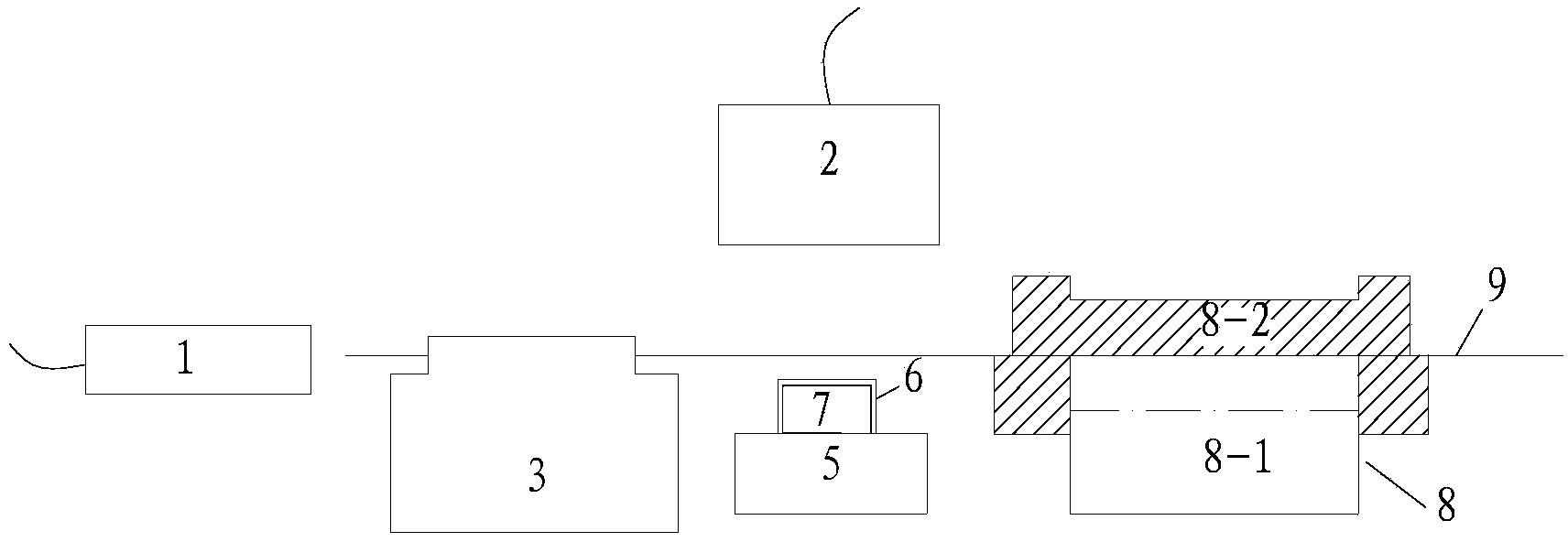

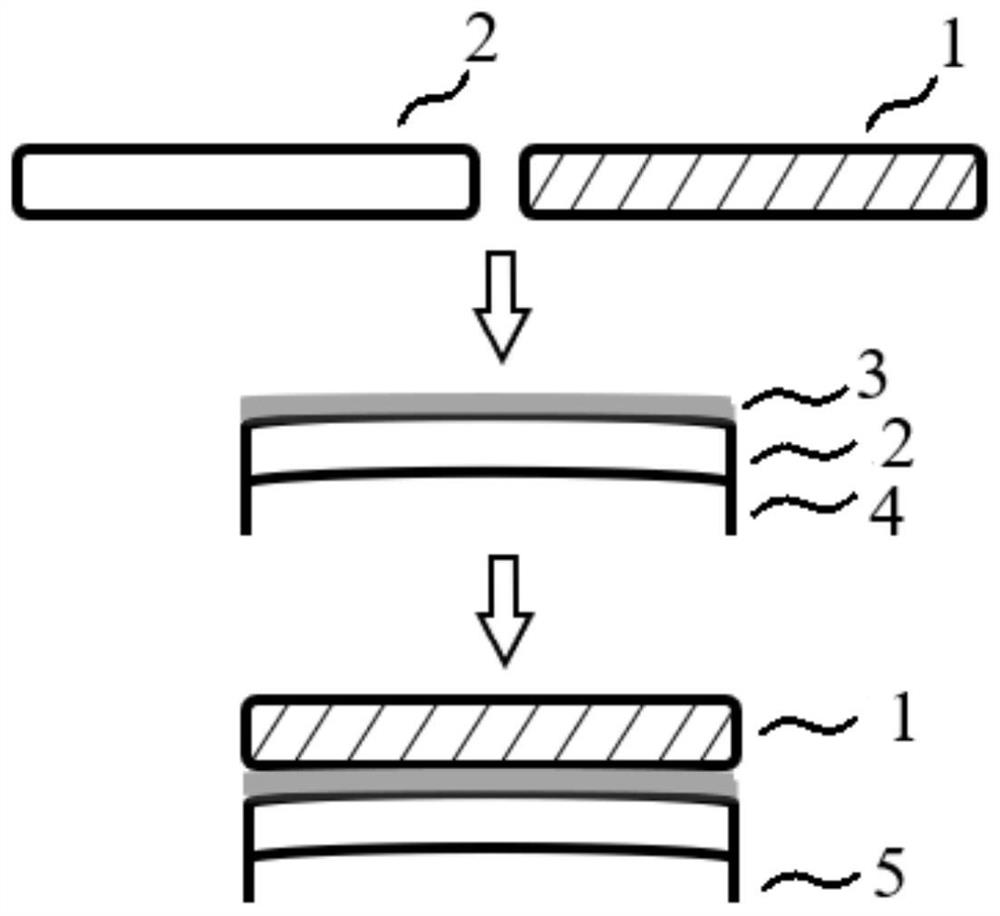

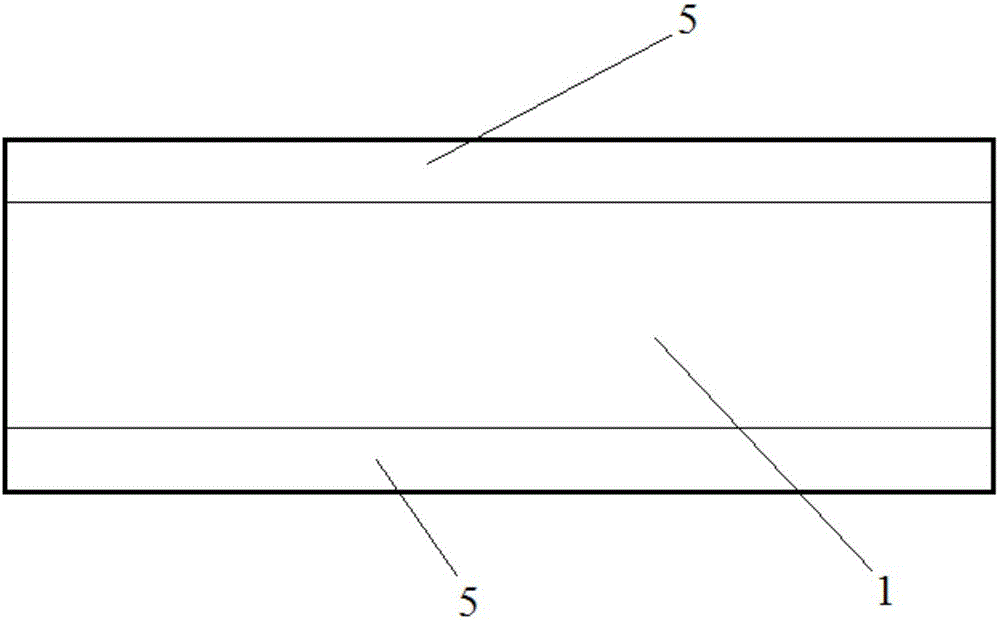

A kind of lithium-ion battery soft coating inner layer material and preparation method thereof

ActiveCN107599576BSolve the problem of low heat sealing strength at high temperatureSolve the problem of low bonding strengthSynthetic resin layered productsSecondary cellsPhysical chemistryLithium-ion battery

A kind of lithium-ion battery soft coating inner layer material, the inner layer material is cast polypropylene film, adopts three-layer structure, respectively is heat-sealing layer, core layer and corona layer from top to bottom; Copolymerized polypropylene, anti-adhesive agent and smooth agent, its mass and number ratio is 100: (1-3): (0.3-1.5); core layer includes binary copolymerized polypropylene and smooth agent, its mass and number ratio For: 100: (1‑3); the corona layer includes a mixture of binary copolymerized polypropylene, terpolymerized polypropylene, carboxyl-terminated polybutadiene liquid rubber and an anti-adhesive agent, and its mass-number ratio is: 100: (5-20): (1-3); the mixture of carboxyl-terminated polybutadiene liquid rubber is mixed in the dipping method, and the dipping ratio concentration with terpolymerized polypropylene is 0.01%-1%. And a preparation method of the inner layer material of the soft coating of the lithium ion battery. The invention has better high-temperature heat-sealing strength, higher adhesiveness with aluminum foil, and higher puncture-resistant strength.

Owner:ZHEJIANG GREAT SOUTHEAST PACKAGING

Manufacture method of low-stress polarization maintaining optical fibre applied to coupling

ActiveCN103145349BReduce stress effectsPrecise positioningOptical fibre with polarisationAdhesiveCoupling

Owner:GUANGXUN SCI & TECH WUHAN

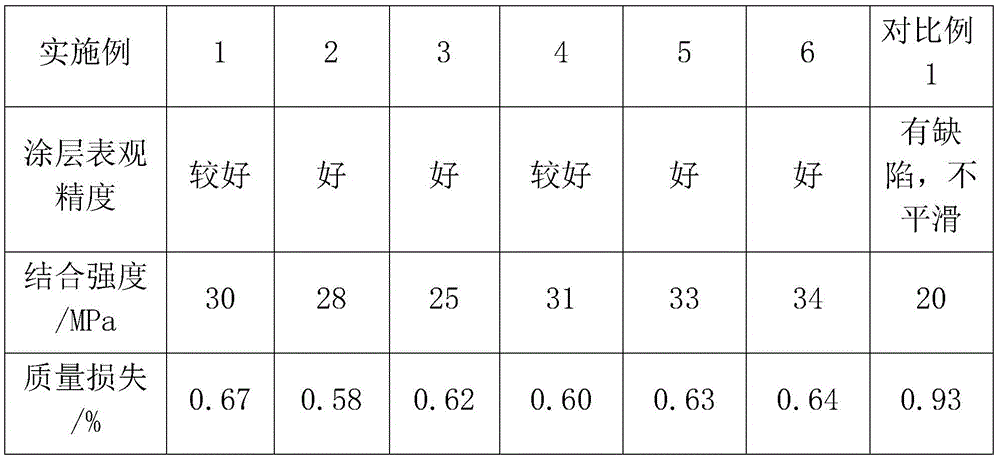

Manufacturing method of wear-proof coating

ActiveCN105458269ASolve the problem of low bonding strengthHigh bonding strengthAbrasive blastingThermal spraying

The invention provides a manufacturing method for a wear-proof coating. The manufacturing method includes the following steps that corrosion rust removal and abrasive blasting and coarsening treatment are conducted on the surface of a base body; a self-fluxing alloy material is sprayed to the coarsened surface of the base body; then self-propagating powder is pressed into a block to be placed on the sprayed surface of the base body and put into a combustion chamber; the base body is preheated, a self-propagating reaction is triggered through ignition, and the base body is naturally cooled after the reaction is finished; and a wear-proof material is sprayed to the surface of the product through the thermal spraying process, and the wear-proof coating is obtained. By means of the method, the problem that the bonding strength of the self-propagating coating and the base body is low can be solved, the bonding strength of the wear-proof coating is improved greatly, the wear-proof layer is added to the self-propagating coating, the wear resistance of the coating can be improved, the voidage of the coating can be lowered, and flatness is improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

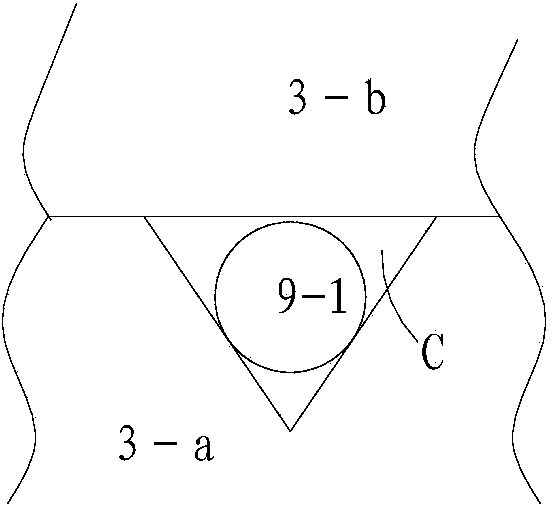

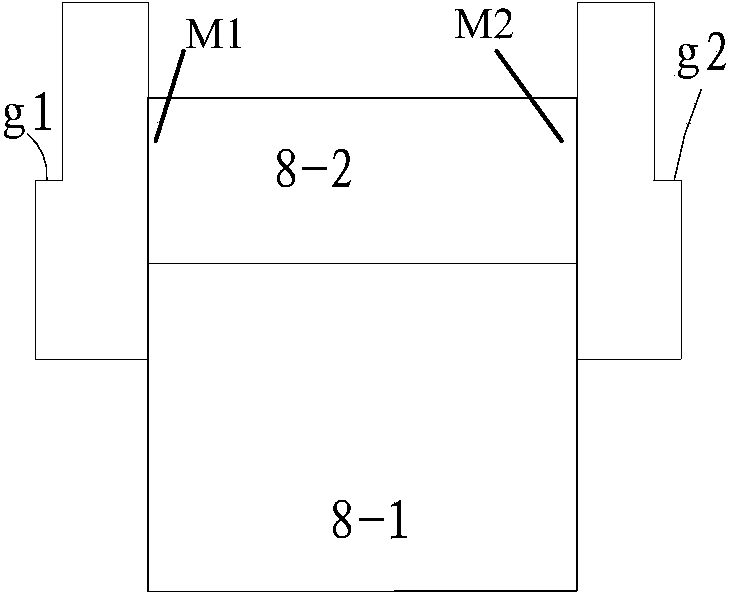

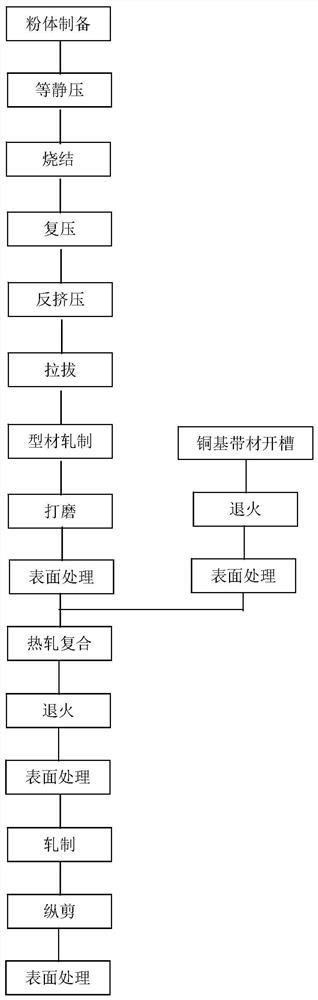

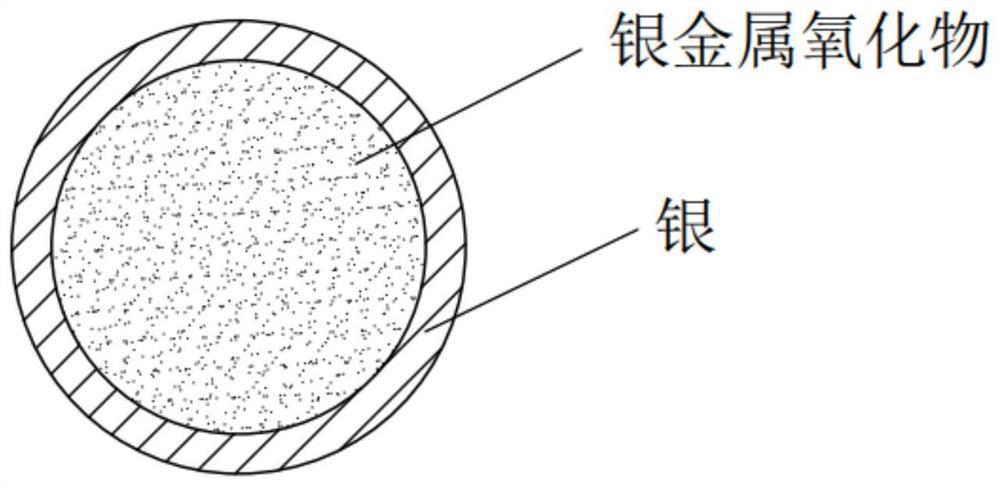

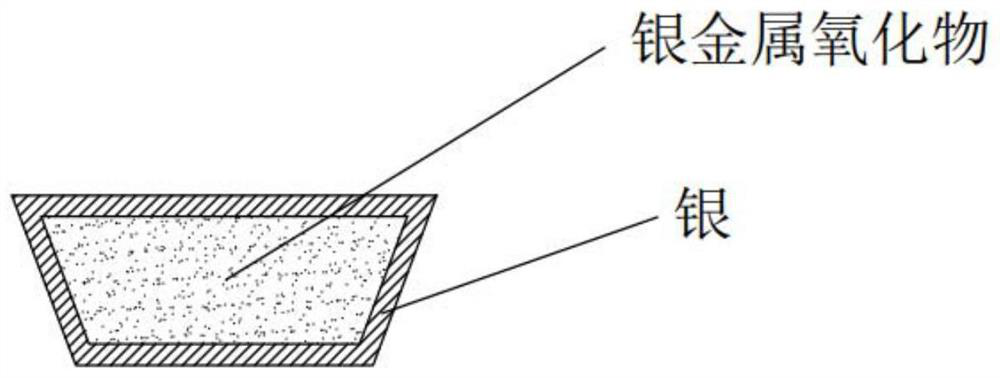

Silver metal oxide inlaid composite strip and preparation method thereof

PendingCN114512359AImprove wettabilityEnhanced atomic diffusion effectCable/conductor manufactureContactsBonding strengthCopper

The preparation method comprises the following steps: preparing a special-shaped strip with a trapezoidal cross section by taking a silver metal oxide composite silver core-spun wire as a raw material, grinding to remove a silver layer on the lower bottom surface of the trapezoidal cross section, and matching with a copper-based strip with a slotted trapezoidal groove, so as to prepare the silver metal oxide embedded composite strip. And the silver metal oxide inlaid composite strip is prepared after hot rolling compounding. According to the invention, the bonding strength between the silver metal oxide and the copper-based material can be effectively improved, especially the bonding strength of the bonding interface between the silver metal oxide of the vertical working surface of the inlaid composite strip and the copper-based material, and the interface is prevented from cracking in the bending forming process.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

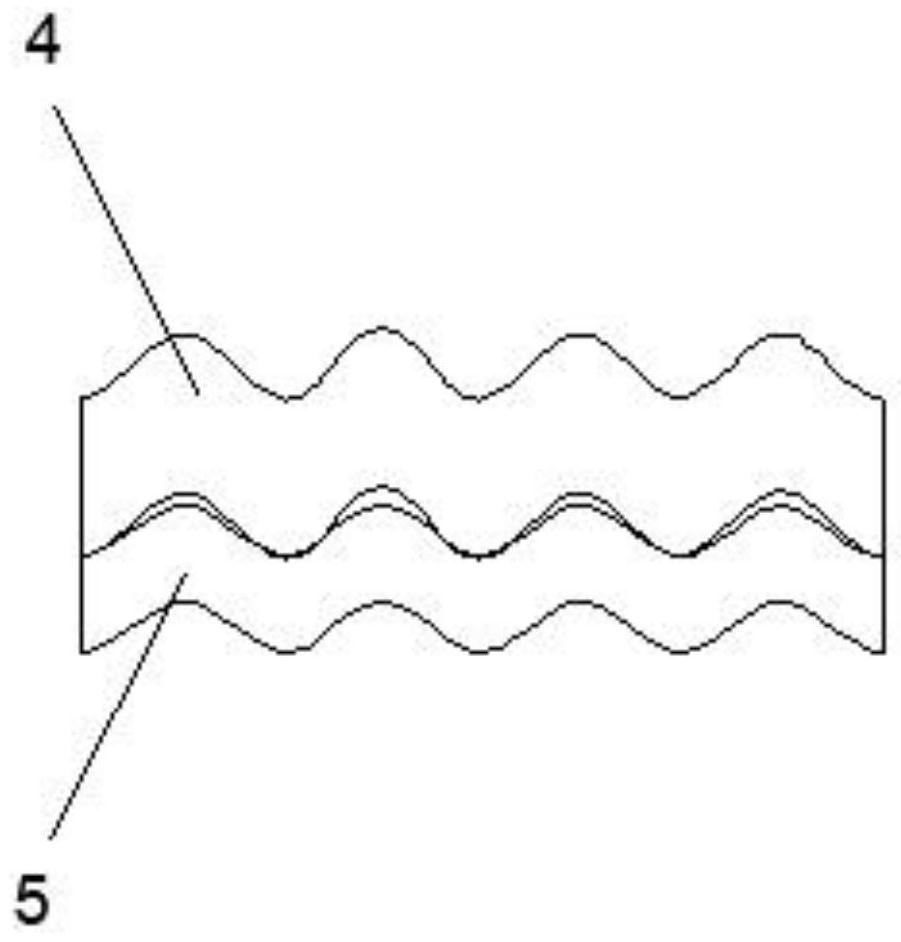

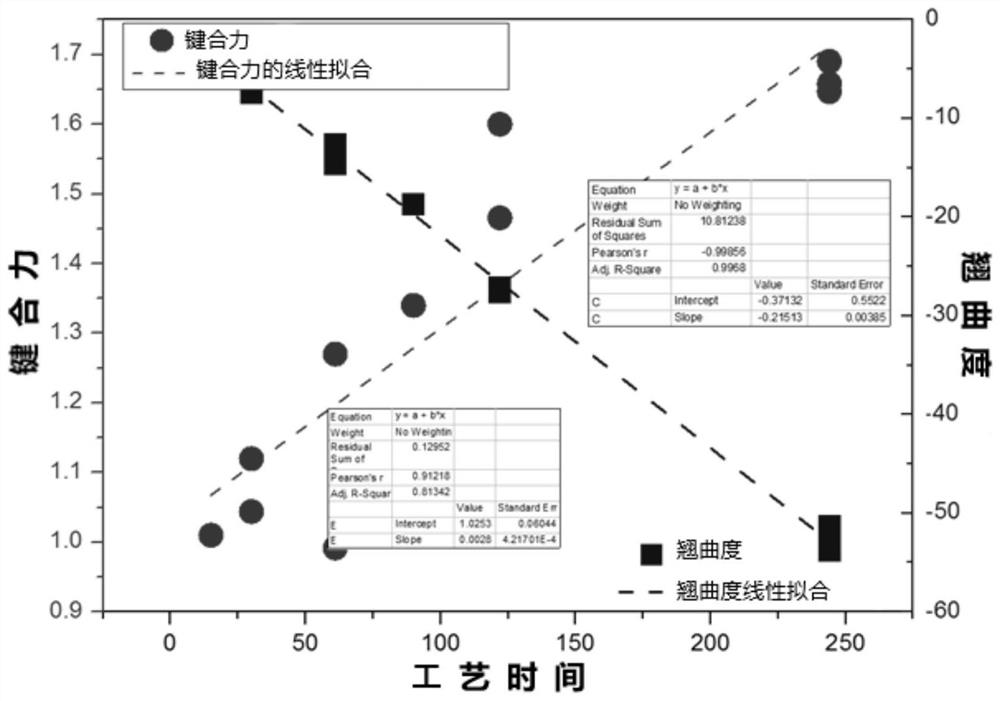

A preparation method of pulse current assisted rolling difficult/easy-to-deform metal composite plate

ActiveCN111054748BSolve the problem of low bonding strengthReduce deformation resistanceWork heating devicesAuxillary arrangementsComposite strengthComposite plate

The invention discloses a preparation method of a pulse current assisted rolling difficult / easy-deformable metal composite plate. The composite plate includes a difficult-deformable metal plate and an easily-deformable metal plate; After pre-rolling assisted by pulse current with small corrugation, the billets are put into a rolling mill equipped with a pulse power supply device for flat roll rolling to obtain a composite plate. The preparation method of the pulse current assisted rolling difficult / easy-to-deform metal disclosed in the present invention utilizes the tip discharge effect and the electroplastic effect to improve the plasticity of the two kinds of metal plates by discharging in the tiny gaps of the metal plates during rolling. Deformation resistance is reduced and residual stresses are relieved, resulting in a metallurgical bond. The preparation method has the advantages of low rolling temperature, less interface brittle compounds, significantly improved microstructure, and the prepared material has good plate shape, high composite strength and good interface bonding performance.

Owner:TAIYUAN UNIV OF TECH

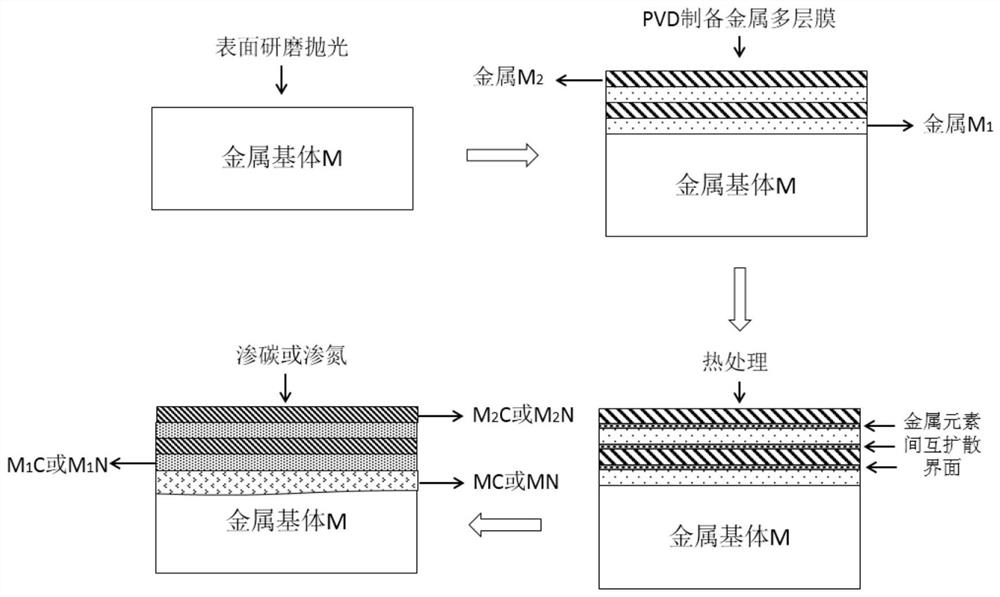

A kind of composite treatment method of coating first and then nitriding on the surface of metal material

ActiveCN103805996BSmall grain sizeReduce defect densityVacuum evaporation coatingSputtering coatingMetallic materialsHigh surface

The invention belongs to the field of material surface modification, and particularly relates to a composite treating method for nitriding the surface of a metal material after coating. The composite treating method is suitable for surface strengthening of tools, molds and metal accessories. The composite treating method comprises the following steps: firstly depositing a layer of nitride thin film on the surface of a metal material substrate by adopting magnetron sputtering or arc ion plating, wherein the thickness of the thin film is 0.1-50 micrometers; then carrying out ion nitriding treatment on the surface of the coating film by adopting an ion nitriding technology for 0.5-10 hours. Due to adoption of the composite treating method, the problem of low film-substrate bonding strength and the like caused by a black layer easily occurring in a composite treating process of coating after nitriding are solved. The workpiece obtained by adopting the coating-nitriding composite treating method of carrying out ion nitriding treatment after depositing a layer of thin film has the characteristics of high surface hardness, good wear resistance, high film-substrate binding force, reliable quality, stability and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for improving silicon wafer bonding force

PendingCN112670170ASolve the problem of low bond strengthOvercome limitationsSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention provides a method for improving silicon wafer bonding force, and is characterized in that a silicon dioxide film grows on one silicon wafer through plasma chemical vapor deposition; and two silicon wafers are bonded and annealed at normal temperature and normal pressure. According to the invention, the problem of low bonding strength of two silicon wafers at normal temperature and normal pressure is solved, the use limitation of the silicon wafers is improved, the available silicon wafer range is expanded, the bonding strength of the bonded silicon wafers is improved, and the yield and quality of products are ensured.

Owner:长春长光圆辰微电子技术有限公司

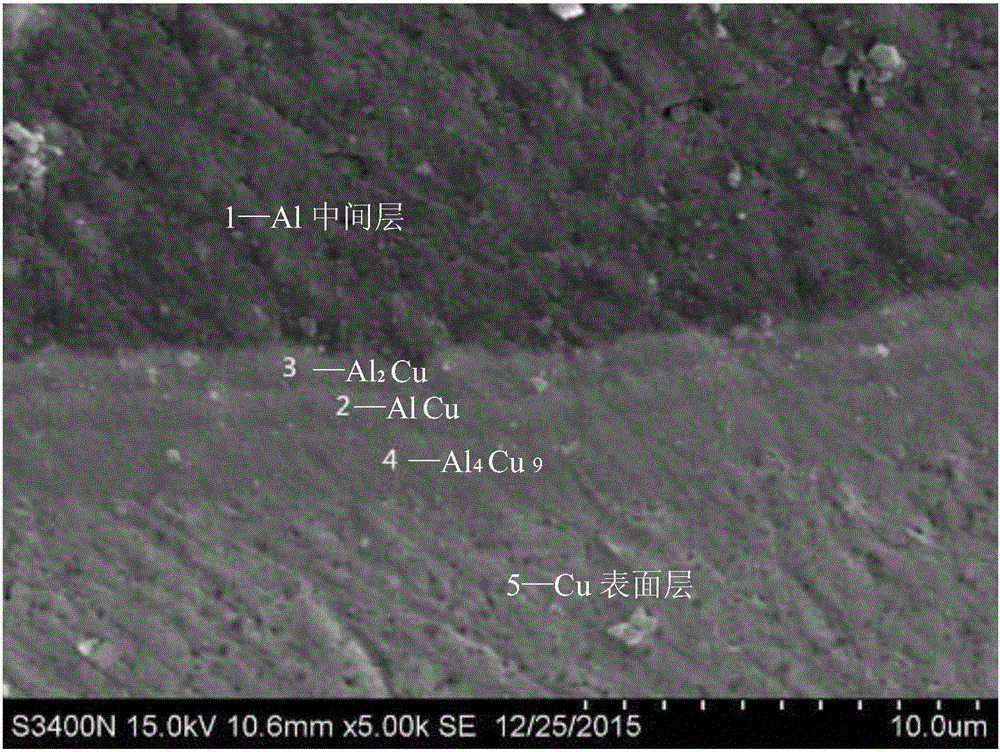

Photovoltaic junction box copper-clad aluminum current-conducting plate and precision rolling compound method thereof

InactiveCN106782746AReduce material costsMeet the comprehensive performance requirementsConductive materialMetal/alloy conductorsComposite plateTwo step

The invention discloses a photovoltaic junction box copper-clad aluminum current-conducting plate and a precision rolling compound method thereof. Firstly, a three-layer pure copper-pure aluminum-pure copper composite plate is selected as a rolling base plate, wherein the thickness of the base plate is 2mm, the thickness after rolling is about 0.7mm, and the thickness ratio of a single-sided pure copper surface layer to a pure aluminum middle layer is 1 to 6. A precision rolling compound process comprises two steps of rolling at room temperature and diffusion annealing, and comprises the concrete steps of firstly precision-rolling the base plate to the required thickness at room temperature, wherein the rolling reduction ratio is 65 percent; then carrying out the diffusion-annealing for 1h at the temperature of 300 DEG C. Layers of a copper-clad aluminum sheet obtained through the invention are in metallurgical bonding in a sawtooth shape; the copper-clad aluminum sheet has both excellent electrical conductivity and less proportion of copper, so that the copper-clad aluminum sheet meets the comprehensive performance requirement of the photovoltaic junction box current-conducting plate, furthermore, the bending resistance is high, and the bonding strength between the composite plates is improved. Since the volume percentage of the aluminum replacing the copper reaches up to 75 percent, the cost of the current-conducting plate is remarkably reduced.

Owner:HOHAI UNIV +1

Method for preparing ceramic multilayer film on metal surface by chemical heat treatment

ActiveCN113621937AImprove interface bonding strength and comprehensive mechanical propertiesImprove grain boundary binding forceVacuum evaporation coatingSputtering coatingMetal metalCarburizing

The invention discloses a method for preparing a ceramic multilayer film on a metal surface by chemical heat treatment. The method comprises the following steps: firstly, preparing a metal / metal multilayer film with carbide or nitride or nitride forming ability on the surface of a metal matrix needing surface strengthening by utilizing a physical vapor deposition method; then performing high-temperature heat treatment on a sample to promote mutual diffusion of metal element layers; lastly, performing carburizing treatment or nitriding treatment or nitriding treatment on the sample, and making the sample react with metal along with inward diffusion of carbon or nitrogen, so that the metal / metal multilayer film is converted into a carbide / carbide nitride / nitride multilayer film; and finally forming a ceramic / ceramic multilayer film on the surface of the matrix. Compared with the prior art, the method has the advantages that mutual diffusion of metal elements of an interlayer interface can be promoted, a high-strength interlayer interface and a film-based interface which are metallurgically bonded are formed, and the comprehensive mechanical property of a film layer is remarkably improved.

Owner:XIAN UNIV OF TECH

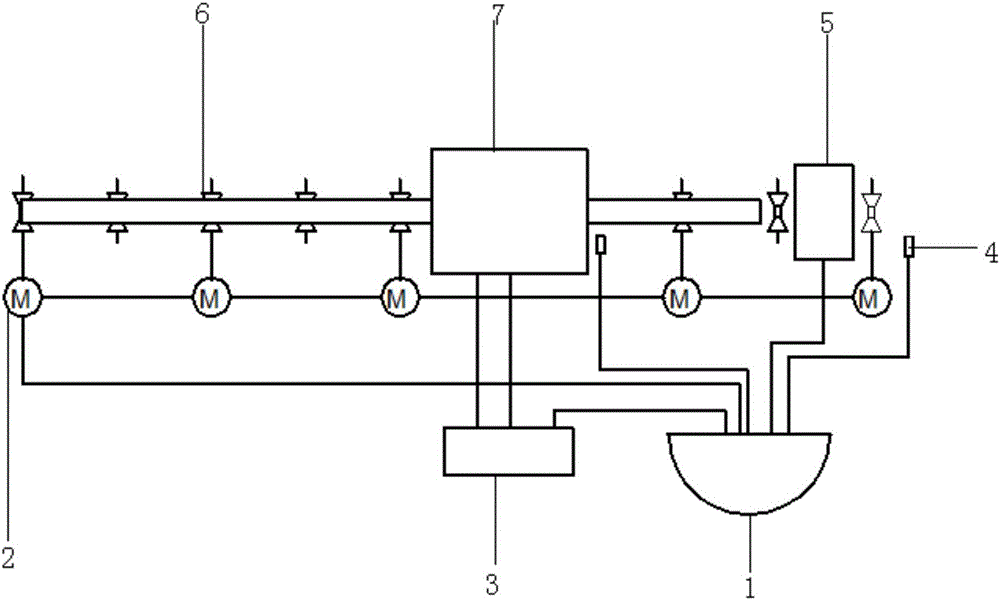

Induction brazing device and method for producing metallurgical composite tubes in atmospheric environment

InactiveCN106270905ASolve the problem of low bonding strengthIncrease productivityHeating appliancesTubular articlesControl systemEnergy consumption

The invention discloses an induction brazing device and method for producing metallurgical composite tubes in the atmospheric environment. The brazing device comprises a control system. The control system is connected with a speed regulating motor set, an induction heating power supply, a thermodetector and a cooling device. The speed regulating motor set is connected with a roller carrier for supporting walking of the composite tubes. An induction heating coil is connected with the induction heating power source, and the induction heating coil, the thermodetector and the cooling device are sequentially arranged in the conveying direction of the roller carrier. The metallurgical metal composite tubes manufactured through the method effectively solve the problem that the bonding strength of mechanical metal composite tube base liners is not high, compared with a complex process of traditional metallurgical composite tubes, no vacuum environment is needed, the process is simple, cost is low, production efficiency is high, energy consumption is low, the bonding strength of base liners is high, and the excellent mechanical performance of base tubes and the anti-corrosion performance of liner tubes are achieved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

A method for preparing wear-resistant coating on steel plate

ActiveCN105463358BSolve the problem of low bonding strengthIncreased durabilityMolten spray coatingSelf-propagating high-temperature synthesisCombustion chamber

The invention provides a method for preparing a wear-resisting coating on a steel plate. The method comprises the following steps that the surface of the steel plate is firstly subjected to corrosion derusting and sand-blasting roughening treatment, a reaction combustion chamber is designed, and a self-fluxing alloy material is sprayed to the roughened surface of the steel plate; and then, self-propagating powder is pressed into blocks to be placed on the surface of a base body obtained after spraying, the base body is put in the combustion chamber, the steel plate is preheated, then ignition is carried out to trigger a self-propagating high-temperature synthetic reaction, and natural cooling is carried out after the reaction is finished. The method has the following beneficial effects that the method can be used for solving the problem that the bonding strength of a coating obtained through self-propagating reaction high-temperature synthesis and the steel plate is not high, and the bonding strength of the wear-resisting coating is greatly improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com