Method for improving silicon wafer bonding force

A technology of bonding force and silicon wafers, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of high surface roughness and integrity of silicon wafers, expand the scope of silicon wafers, solve limitations, Guarantee the effect of yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

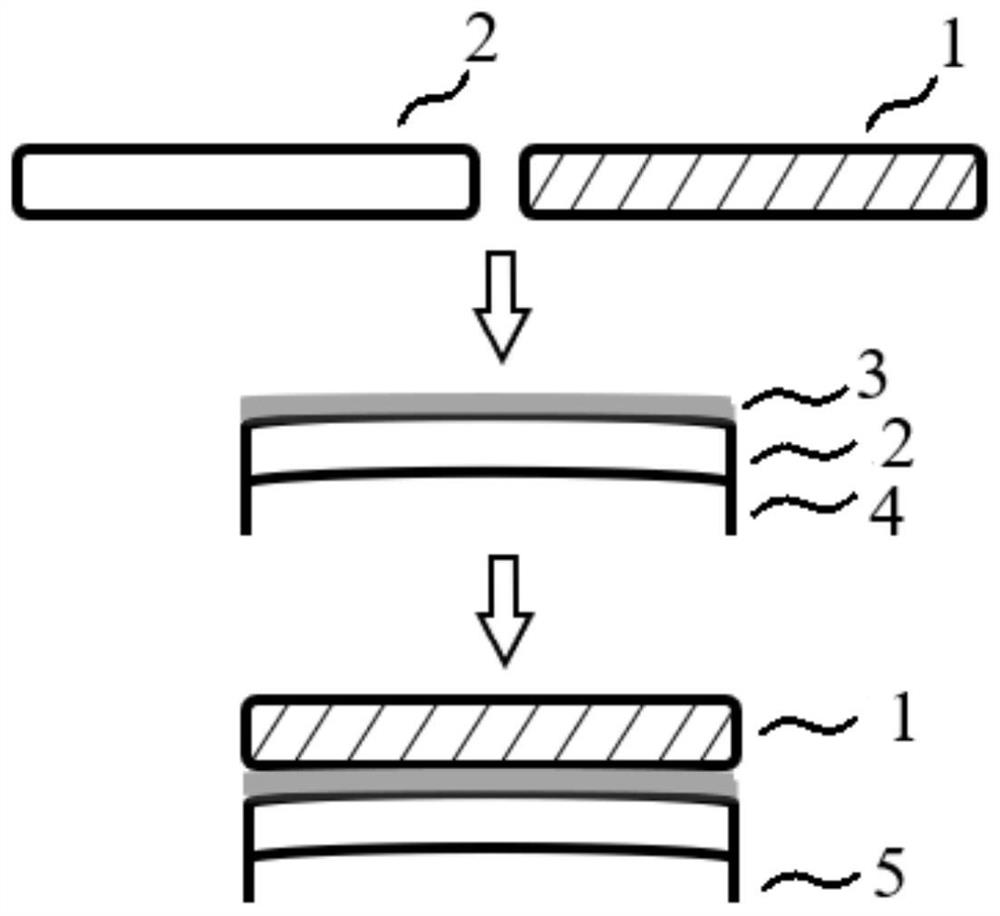

[0030] The present invention provides a method for improving the bonding force of silicon wafers. A silicon dioxide film 3 is grown on one of the silicon wafers using a plasma chemical vapor deposition process, so that the warpage (bow value) of the silicon wafers is about -50 μm, and then the The two silicon wafers are bonded and annealed at normal temperature and pressure, thereby improving the bonding force of the silicon wafers.

[0031] Such as figure 1 It is an experimental flow chart of a method for improving the bonding force of silicon wafers of the present invention.

[0032] Such as figure 1 Shown, the specific operation steps of the present invention are:

[0033] S1: Prepare two silicon wafers; and set one as the upper silicon wafer 1 to be bonded, and the other as the lower silicon wafer 2 to be bonded.

[0034] S2: Select the lower silicon wafer 2 to perform a film deposition process, and grow a silicon dioxide film 3 on the surface;

[0035] S3: Bonding two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com