Method for preparing organic silicon modified aqueous polyurethane adhesive

A water-based polyurethane and adhesive technology, applied in the directions of adhesives, adhesive types, starch-derived adhesives, etc., can solve problems such as reduced bonding performance, achieve enhanced bonding performance, improve peel strength, and solve the problem of bonding The effect of reduced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

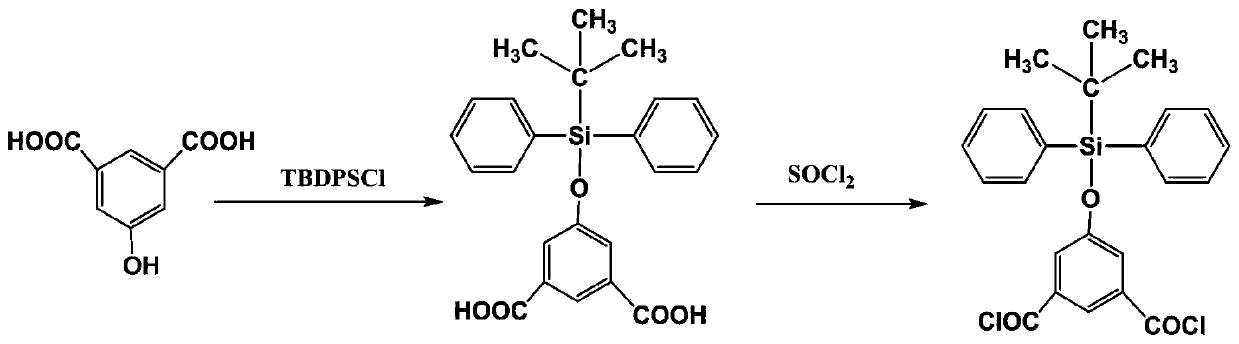

[0024] ①Weigh 1kg of 5-hydroxyisophthalic acid and dissolve it in 15L of pyridine, add 1kg of imidazole and 1.52kg of tert-butyldiphenylchlorosilane to it after heating up to 50°C, react at constant temperature for 2 hours, then use deionized water and saturated chlorine respectively Sodium chloride was washed, then dried with sodium sulfate and then rotary evaporated, and finally the column was carried out to obtain pure product A;

[0025] ② Add 1 kg of the product A prepared in step ① to 15 LN,N-dimethylformamide, heat up to 80°C, add 2.32 kg of thionyl chloride to it, react at constant temperature for 5 hours, and then filter and wash to obtain bisacyl chloride prepolymer.

Embodiment 2

[0027] A preparation method of silicone modified water-based polyurethane adhesive, comprising the following preparation process:

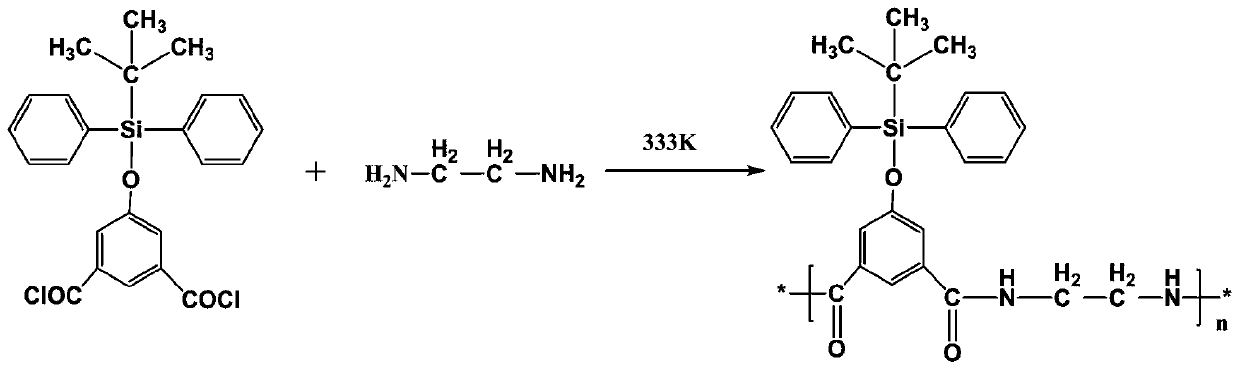

[0028] In the first step, add 1kg of the bisacyl chloride-based prepolymer prepared in Example 1 into 10L of acetone, raise the temperature to 60°C, and at the same time add 2.5L of ethylenediamine solution to the reaction vessel, react at constant temperature for 3 hours, then directly filter, wash and dry , to obtain modified polyurethane polymer;

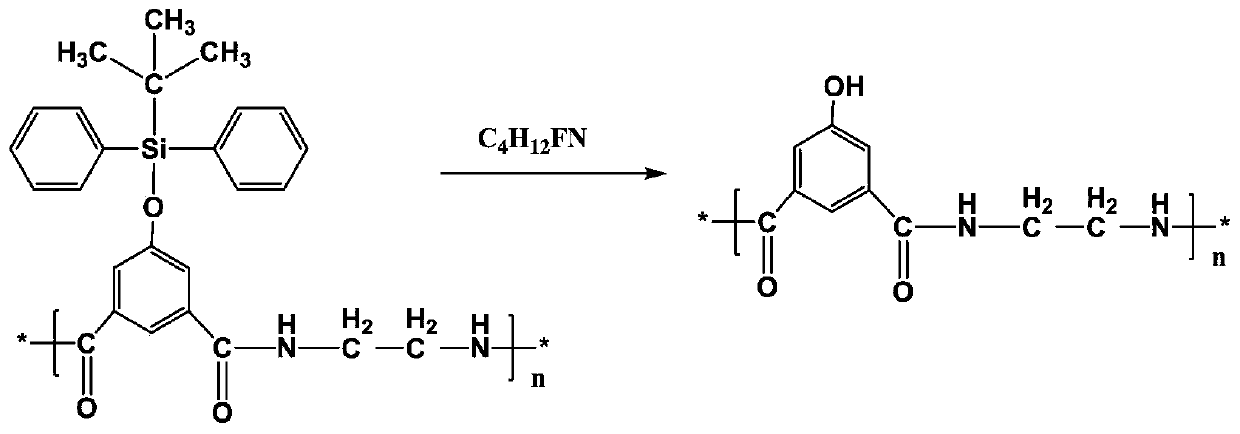

[0029] In the second step, add 1kg of the modified polyurethane polymer prepared in the first step into water, raise the temperature to 70°C, then add 0.86kg of tetramethylammonium fluoride to it, react at constant temperature for 5 hours, and then wash it with deionized water drying to obtain a hydroxylated modified polyamide polymer;

[0030] The third step is to weigh a certain amount of oxidized starch and dissolve it in acetone to form an oxidized starch solution with a concentration of 200g / L....

Embodiment 3

[0033] A preparation method of silicone modified water-based polyurethane adhesive, comprising the following preparation process:

[0034] In the first step, add 1kg of the bisacyl chloride-based prepolymer prepared in Example 1 into 12L of acetone, raise the temperature to 60°C, and at the same time add 3L of ethylenediamine solution to the reaction vessel, react at constant temperature for 3h, then directly filter, wash and dry, Obtain modified polyurethane polymer;

[0035] In the second step, add 1kg of the modified polyurethane polymer prepared in the first step into water, raise the temperature to 70°C, then add 0.89kg of tetramethylammonium fluoride to it, react at constant temperature for 5 hours, and then wash it with deionized water drying to obtain a hydroxylated modified polyamide polymer;

[0036] The third step is to weigh a certain amount of oxidized starch and dissolve it in acetone to form an oxidized starch solution with a concentration of 200g / L. Add 1kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com